Combined brush assembly for wind power sliding ring

A combined brush technology, which is applied to electrical components, circuits, collectors, etc., can solve the problems of difficulty in making brush components, high manufacturing costs, and precious metal consumption, so as to facilitate mass production, ensure product quality, and The effect of saving the use of precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

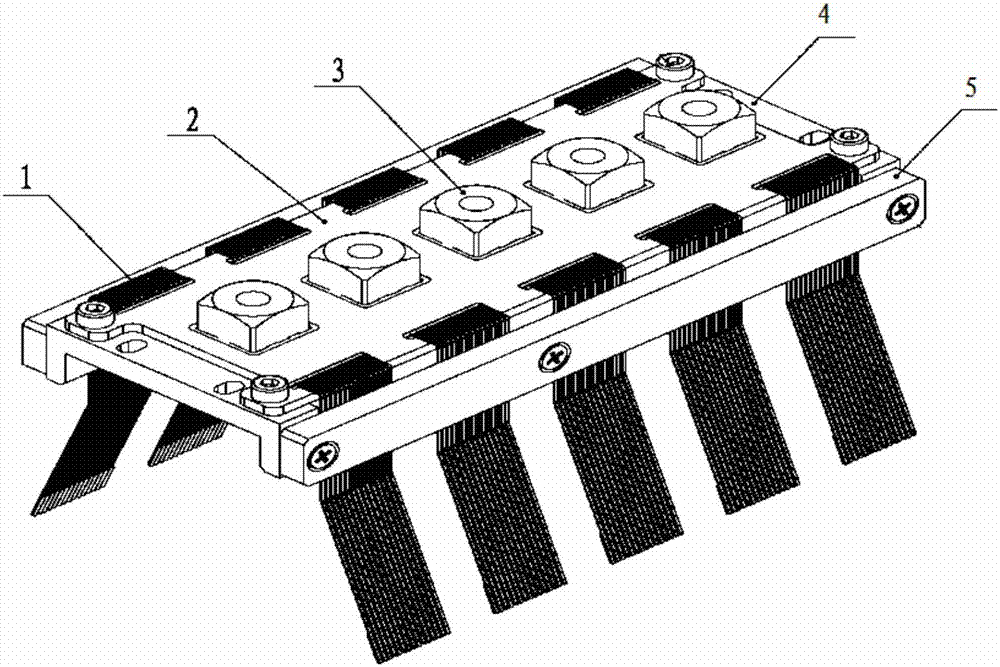

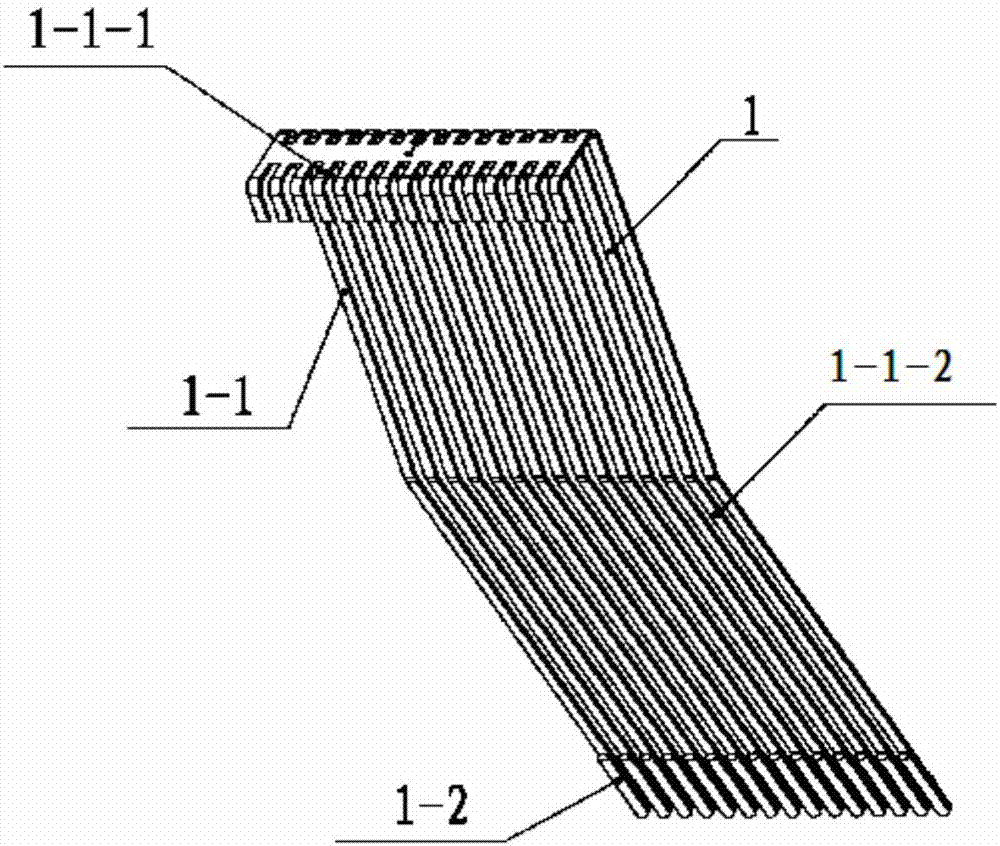

[0024] Such as figure 1 Shown is a schematic structural diagram of a combined brush assembly. It can be seen from the figure that a combined brush assembly for a wind power slip ring includes a brush 1, a printed circuit board 2, a terminal 3, a support plate 4 and a side pressure plate 5; Wherein, the support plate 4 is a rectangular structure placed horizontally, and the middle part of the lower surface of the support plate 4 is provided with grooves along the long side direction; the printed circuit board 2 is a rectangular structure placed horizontally, and the printed circuit board 2 is fixedly installed on the support plate 4 on the upper surface; n brushes 1 are stacked at equal intervals and fixedly installed on both sides of the printed circuit board 2 along the long side direction; m wires are evenly arranged on the midline of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com