Preparation method of high-temperature serving welding point based on tin-filled foamy copper

A technology of high-temperature service and foam copper, which is applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of electromigration reliability, long welding time, reliability problems, etc., and achieve shortened preparation cycle, short welding time, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

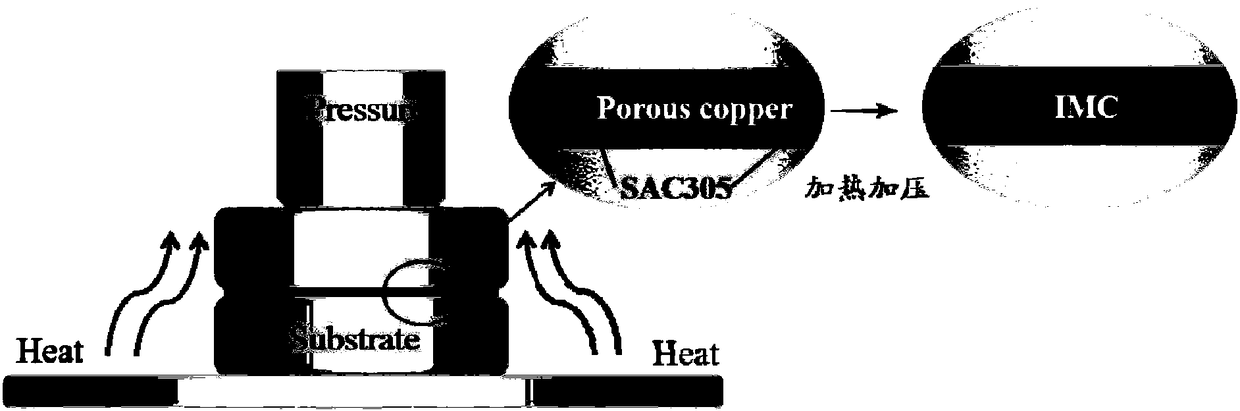

[0040] Embodiment 1, reference figure 1 :

[0041] After a lot of experiments, we invented the welding method in which tin-filled foamed copper is used as the intermediate layer in the schematic diagram, so that solder joints that can be used for high temperature service can be obtained by welding at a lower temperature and less pressure for a short time.

Embodiment 2

[0042] Embodiment 2, refer to figure 2 and image 3 :

[0043] according to figure 1 Welding method, to obtain figure 2 Solder joint structure ( image 3 Enlarged picture of the inside of the solder joint). The method specifically includes the following steps (using a dealloying corrosion method to obtain a foamed copper sheet, stencil printing SAC305 solder paste on both sides of the foamed copper sheet, heating and pressurizing welding and obtaining high-temperature serviceable solder joints as an example):

[0044] (1), Cu with a size of 10mm*10mm*0.2mm 40 Al 60 The alloy flakes were placed in dilute hydrochloric acid solution (10wt.%), and selectively corroded in a water bath environment at 80°C for 12 hours until no obvious bubbles were formed on the surface of the alloy flakes, and a copper foam sheet with a pore size of about 300nm was obtained.

[0045] (2), use distilled water to repeatedly rinse the foamed copper sheet obtained in step (1), then use filter p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com