Temperature-equalizing plate and device and method for manufacturing temperature-equalizing plate

A technology of vapor chamber and cover plate, used in manufacturing tools, lighting and heating equipment, indirect heat exchangers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

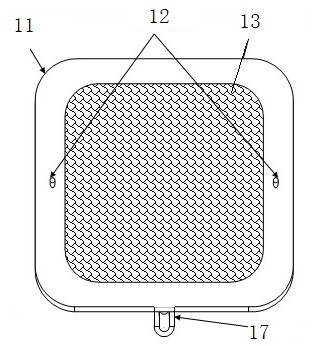

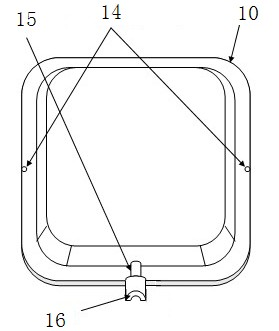

[0050] Combine below figure 2 and Figure 12 , the present invention is further described:

[0051] Such as figure 2 and image 3As shown, the lower cover 11 is symmetrically provided with two fixing pins 12 , and the upper cover 10 is correspondingly provided with two circular holes 14 . When the upper cover plate 10 is joined with the lower cover plate 11, the fixed pins 12 are inserted into the corresponding circular holes 14 on the upper cover plate 10 to fix the upper and lower cover plates, so that the upper cover plate 10 and the lower cover plate 11 are welded together by ultrasonic welding. No shifting will occur.

[0052] A third semicircular protrusion 17 is provided at the edge of the lower cover 11 , and a first semicircular protrusion 15 and a second semicircular protrusion 16 are also provided at the edge of the upper cover 10 . The first semicircular protrusion 15 and the second semicircular protrusion 16 are located on the same straight line. Wherein, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com