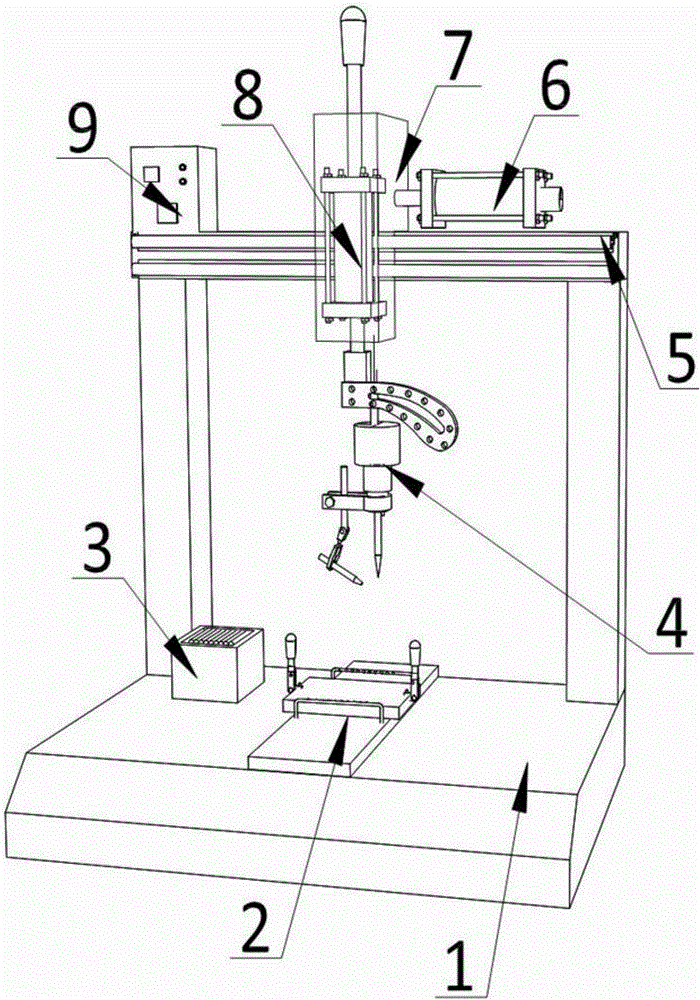

Horizontal sliding rail-type pose self-adjusting welding machine and control method thereof

A slide rail type, welding machine technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of jamming and high failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

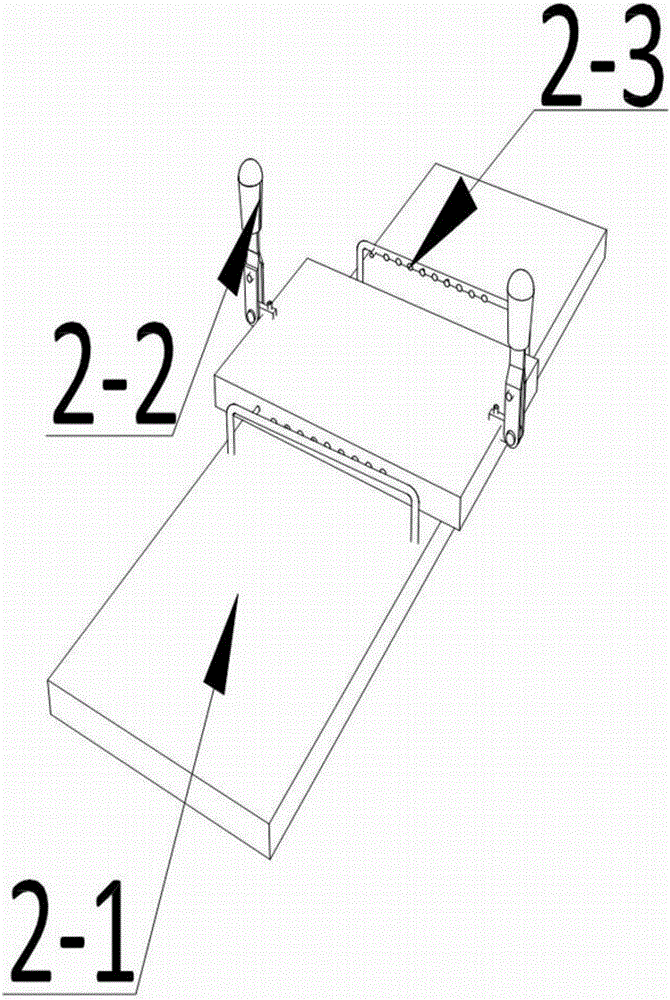

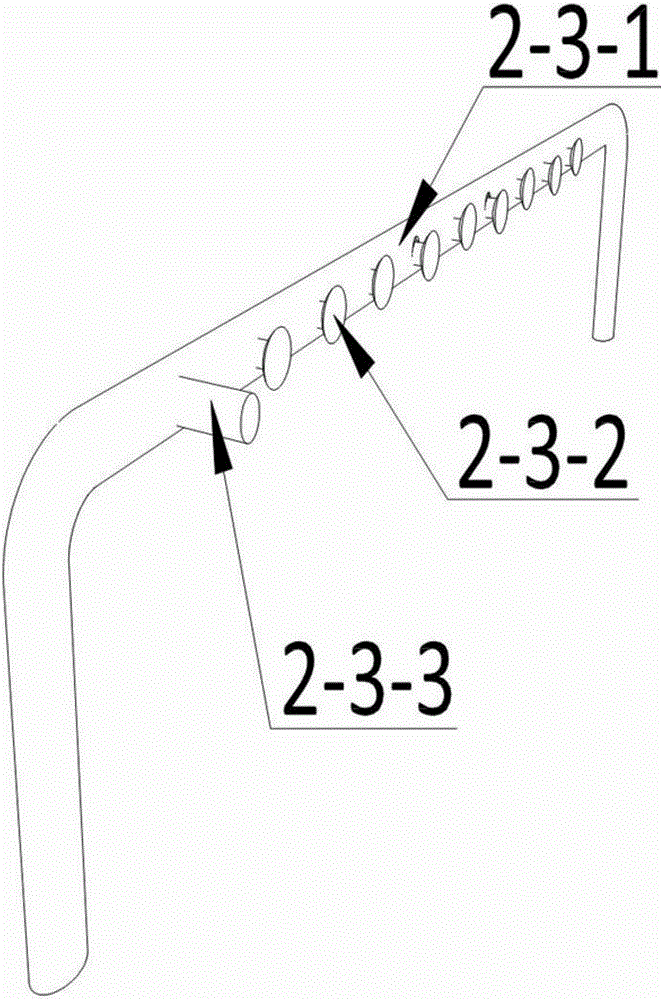

Method used

Image

Examples

Embodiment 1

[0057] The solder pin 4-4 of the present invention is manufactured according to the following steps, and is calculated in parts by weight:

[0058] Step 1: Add 1600 parts of ultrapure water with conductivity of 1.15μS / cm to the reactor, start the stirrer in the reactor, rotate at 51 rpm, start the heat pump, and increase the temperature in the reactor to 63℃; add sequentially 42 parts of 2-methoxy-4-prop-1-propenyl-1-benzyloxybenzene, 2,2-dimethyl-3-(2-methyl-1-propenyl)-cyclopropanecarboxylic acid 13 parts of 4-(methoxymethyl)-benzyl ester, (S)-3-allyl-2-methyl-4-oxo-cyclopent-2-enyl(1R,3R)-2, 58 parts of 2-dimethyl-3-(2-methyl-1-propenyl)cyclopropane carboxylate, stir until completely dissolved, adjust the pH to 5.3, adjust the stirrer speed to 128rpm, and the temperature to 78℃ , Esterification reaction for 18 hours;

[0059] Step 2: Take 33 parts of α-cyano-3-phenoxybenzyl (IRS) cis-3-(2,2-dibromovinyl)-2,2-dimethylcyclopropane carboxylate , (R,S)-α-cyano-3-phenoxybenzyl(1R,...

Embodiment 2

[0064] The solder pin 4-4 of the present invention is manufactured according to the following steps, and is calculated in parts by weight:

[0065] Step 1: Add 1820 parts of ultrapure water with a conductivity of 3.82μS / cm to the reactor, start the stirrer in the reactor, rotate at 71 rpm, start the heat pump, and increase the temperature in the reactor to 83°C; add sequentially 58 parts of 2-methoxy-4-prop-1-propenyl-1-benzyloxybenzene, 2,2-dimethyl-3-(2-methyl-1-propenyl)-cyclopropanecarboxylic acid 38 parts of 4-(methoxymethyl)-benzyl ester, (S)-3-allyl-2-methyl-4-oxo-cyclopent-2-enyl(1R,3R)-2, 83 parts of 2-dimethyl-3-(2-methyl-1-propenyl) cyclopropane carboxylate, stir until completely dissolved, adjust the pH to 7.5, adjust the stirrer speed to 158rpm, and the temperature to 122°C , Esterification reaction for 21 hours;

[0066] Step 2: Take 55 parts of α-cyano-3-phenoxybenzyl (IRS) cis-3-(2,2-dibromovinyl)-2,2-dimethylcyclopropane carboxylate , (R,S)-α-cyano-3-phenoxybenz...

Embodiment 3

[0071] The solder pin 4-4 of the present invention is manufactured according to the following steps, and is calculated in parts by weight:

[0072] Step 1: Add 1950 parts of ultrapure water with a conductivity of 5.43μS / cm to the reactor, start the stirrer in the reactor, rotate at 96rpm, start the heat pump, and increase the temperature in the reactor to 105°C; add sequentially 78 parts of 2-methoxy-4-prop-1-propenyl-1-benzyloxybenzene, 2,2-dimethyl-3-(2-methyl-1-propenyl)-cyclopropanecarboxylic acid 65 parts of 4-(methoxymethyl)-benzyl ester, (S)-3-allyl-2-methyl-4-oxo-cyclopent-2-enyl(1R,3R)-2, 102 parts of 2-dimethyl-3-(2-methyl-1-propenyl)cyclopropane carboxylate, stir until completely dissolved, adjust the pH to 9.7, adjust the stirrer speed to 188rpm, and the temperature to 146°C, Esterification reaction for 25 hours;

[0073] Step 2: Take 86 parts of α-cyano-3-phenoxybenzyl (IRS) cis-3-(2,2-dibromovinyl)-2,2-dimethylcyclopropane carboxylate , (R,S)-α-cyano-3-phenoxybenzy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com