Flexible-tooth threshing system with adjustable threshing gap

A technology of threshing teeth and gap adjustment, which is applied in the field of threshing systems, can solve the problems of being unable to adapt to the threshing requirements of materials to be threshed, the impact force of rapeseed pods is large, and the threshing gap remains unchanged, so as to achieve prolonged action time, high productivity, and fast threshing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

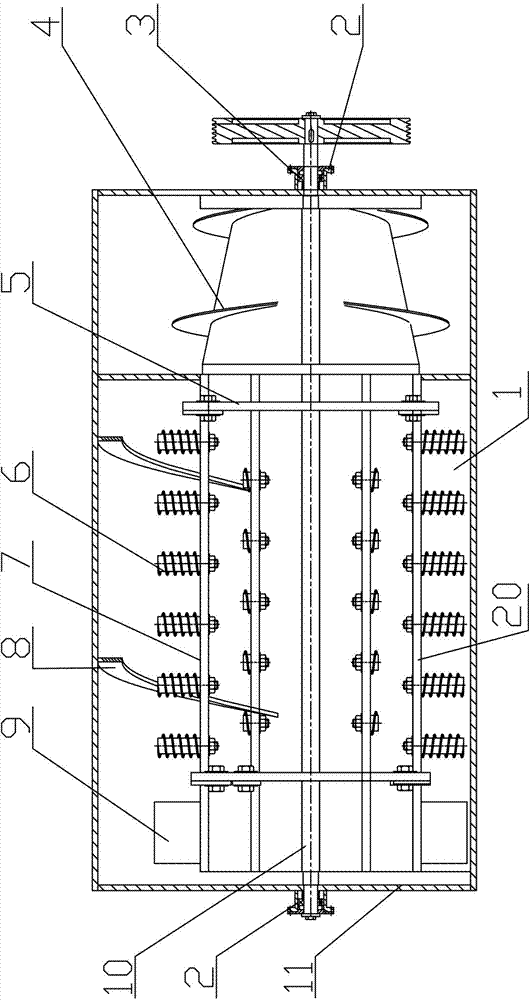

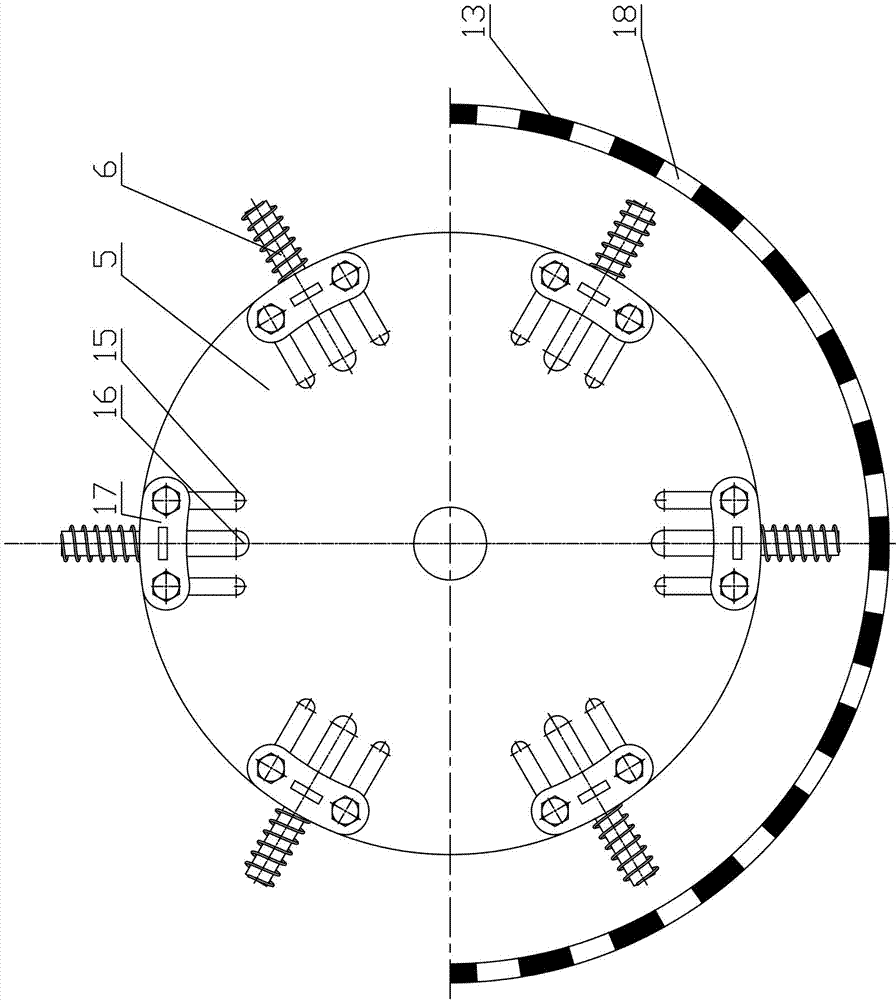

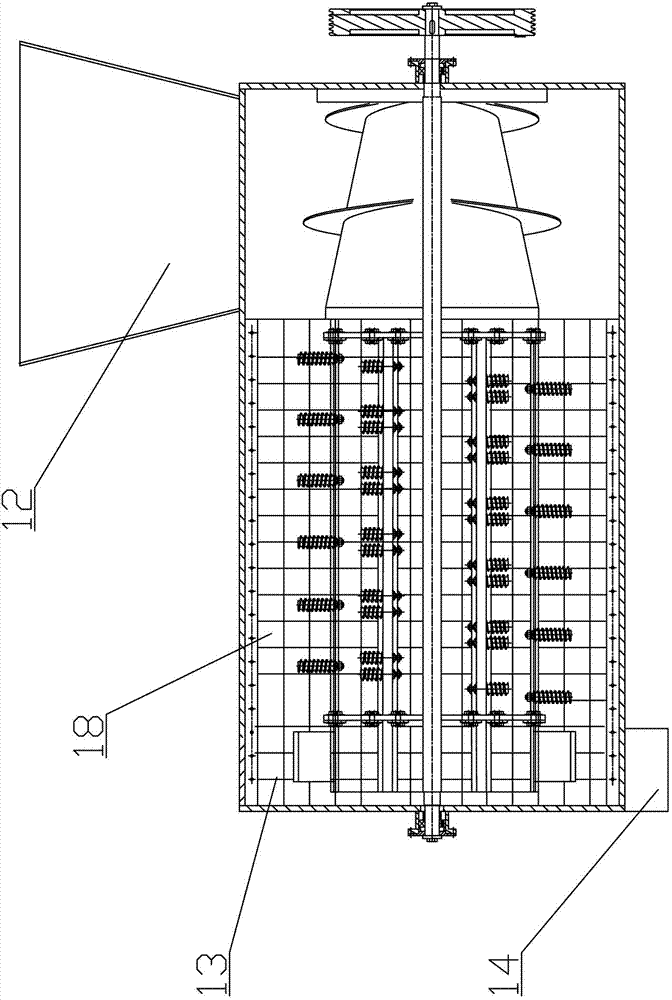

[0026] see Figure 1-Figure 4 , The flexible tooth threshing system with adjustable threshing gap of the present invention includes a threshing drum 20 installed on the frame 2 via a drum shaft 10 and a concave screen 13 installed below the threshing drum 20 . The drum shaft 10 is installed on the frame 2 through the drum support bearing 3, and the concave screen 13 is provided with a plurality of through holes 18 for convenient separation of oil seeds. The outer side of the threshing drum 20 is covered with a drum casing 11 , and a threshing chamber 1 is formed in the drum casing 11 . The threshing drum 20 is located in the threshing chamber 1, and includes two gap adjustment end plates 5 fixed on the drum shaft 10, and a plurality of threshing tooth fixing rods 7 with flexible threshing nail teeth 6 are arranged between the two gap adjustment end plates 5 . The drum shaft 10 at the input end of the threshing drum is provided with a feeding auger 4 distributed in a spiral s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com