Diameter-adjustable corn threshing and flow cutting roller

A technology of corn threshing and cutting flow drum, which is applied in threshing equipment, application, agricultural machinery and tools, etc. It can solve the problems of reducing farmers' income, destroying food security, and clogging of threshing drums, so as to reduce the rate of grain damage and machine failure rate , increase grain production and farmers' income, and the effect of high-efficiency threshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

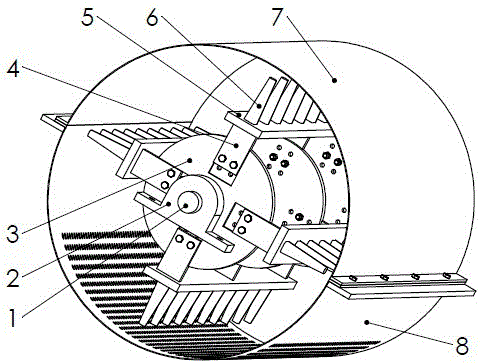

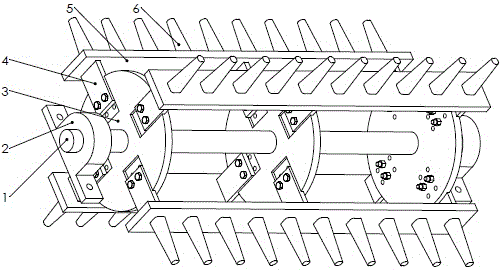

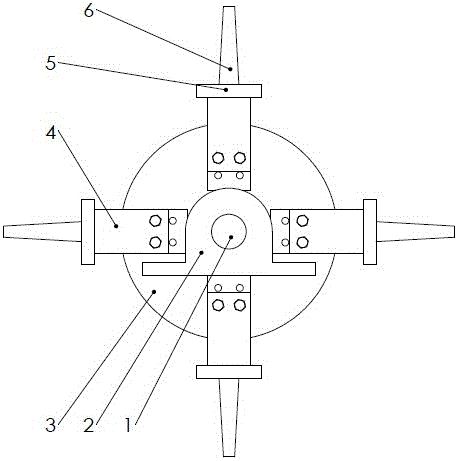

[0016] Refer to the attached figure 1 to attach Image 6 A diameter-adjustable corn threshing cutting drum of the present invention will be described in detail below.

[0017] A diameter-adjustable corn threshing shearing drum, including a rotating shaft 1, a bearing seat 2, a spoke disc 3, a connecting seat 4, a support rod 5, a threshing rod tooth 6, an upper cover plate 7, and a lower concave plate 8, characterized in that, The rotating shaft 1 is matched with the bearing seat 2, the spoke disk 3 is connected with the rotating shaft 1 through a key connection, the connecting seat 4 is connected with the spoke disk 3 through bolts, and the support rod 5 is welded It is connected with the connection seat 4, the threshing rod tooth 6 is connected with the support rod 5 by welding, and the upper cover plate 7 is aligned with the lower concave plate 8 and then connected by bolts.

[0018] Further, there are 3 spoke disks 3, which can be increased with the increase of the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com