Self-adaption regulation system for threshing segregation loads of tangential flow and longitudinal axial flow devices

一种自适应调控、脱粒分离的技术,应用在脱粒设备、应用、切割器等方向,能够解决籽粒破碎率、夹带损失率增大、缺乏调节结构等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

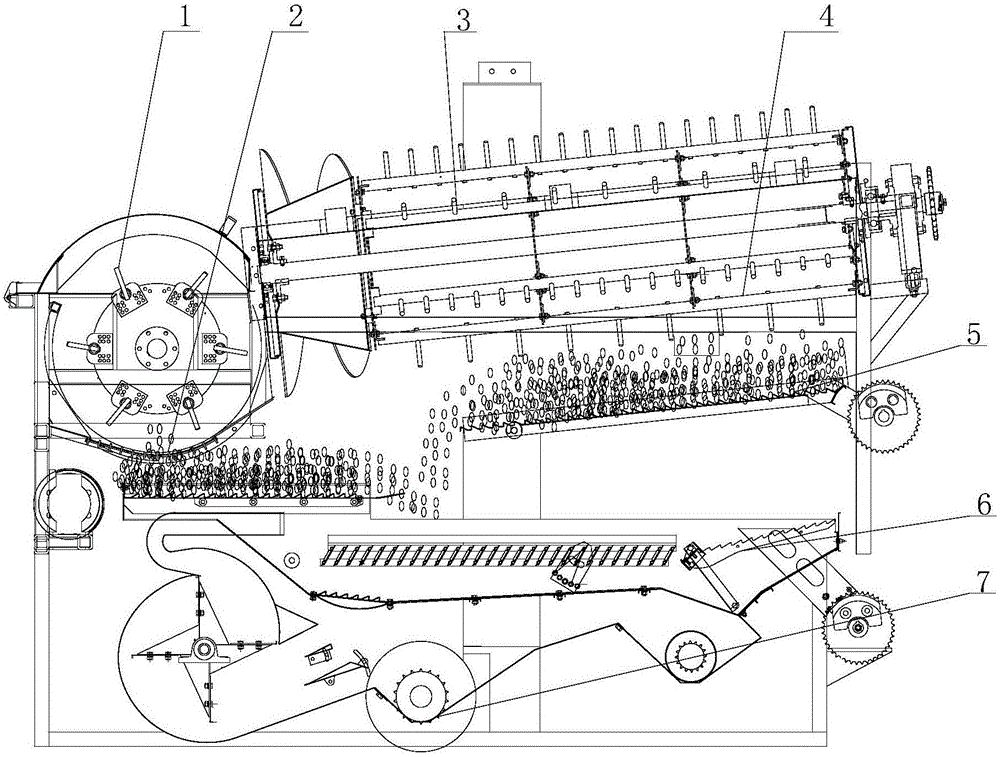

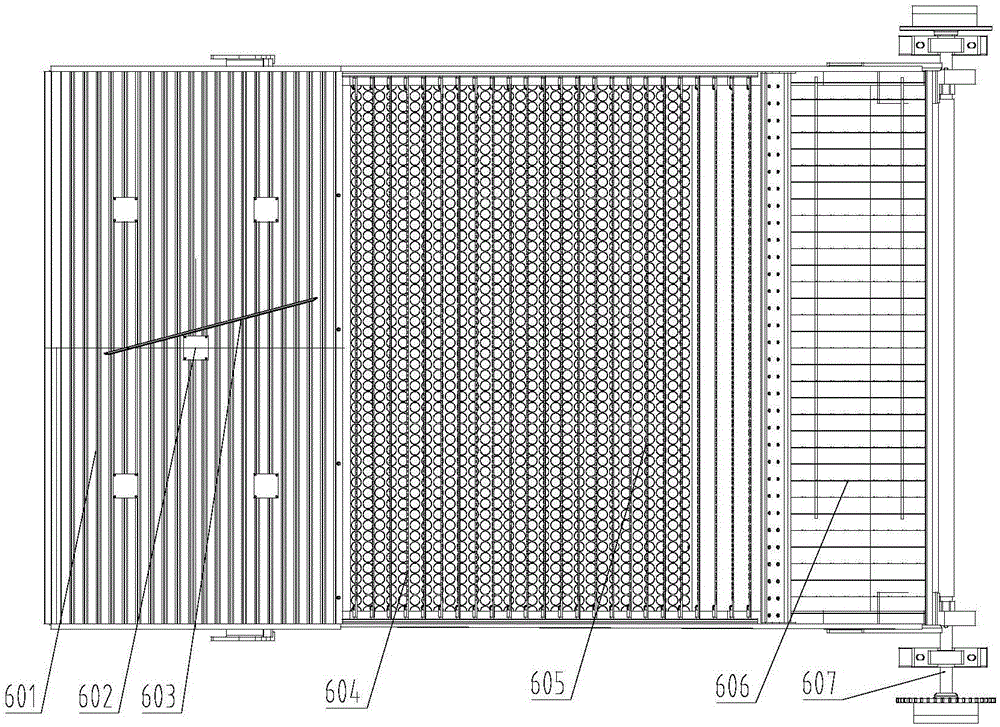

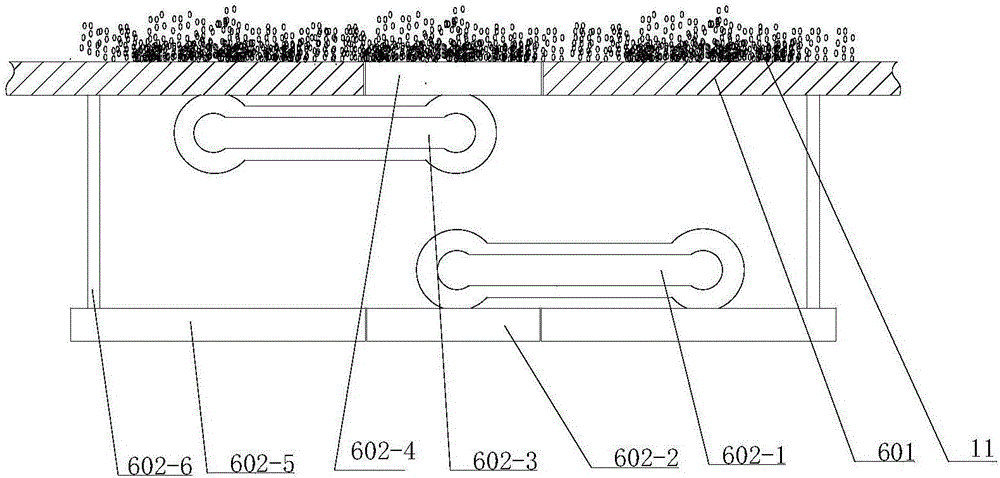

[0064] The structure of the self-adaptive control system of the threshing separation load of the cutting flow and longitudinal axial flow device described in the present invention is as follows: figure 1 As shown, the cutting flow and longitudinal axial flow threshing separation device consists of a cutting flow drum 1, a cutting flow concave plate 2, a longitudinal axial flow drum 3, a longitudinal axial flow concave plate sieve 4, a return plate 5, a cleaning screen 6, and a grain auger 7. Composed of entrainment loss monitoring device 8, grain crushing rate monitoring device 9 and cutting flow concave plate outlet gap adjustment device 10; the shaking plate 601 is located below the cutting flow drum 1, and the longitudinal axial flow concave plate sieve 4 is installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com