Preparation technology of coated material

A preparation process and coating technology, applied in the field of coating material preparation technology, can solve the problems of reservoir damage, inability to self-suspend, and high fracturing cost, achieve energy-saving production efficiency, save the liquid dispensing process and equipment, reduce Damage and Effects of Fracturing Costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

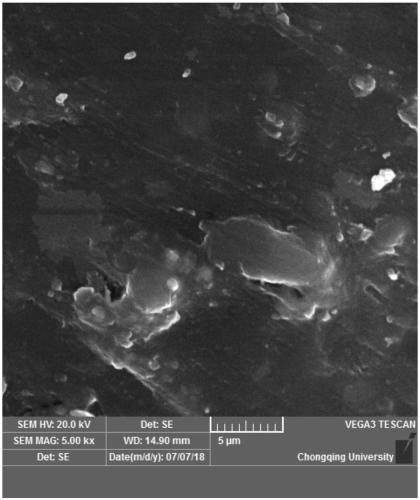

Image

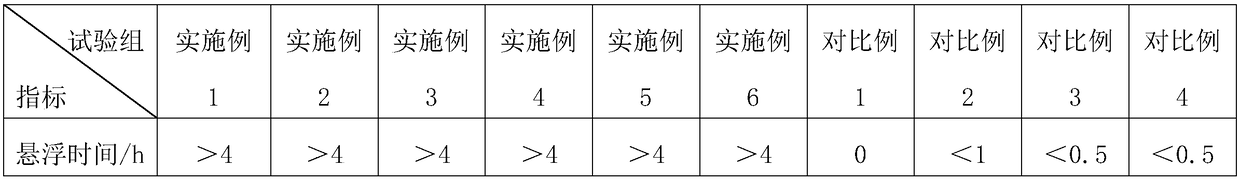

Examples

preparation example Construction

[0033] A preparation method of a coating material, comprising the following steps:

[0034] (1) Prepare the following raw materials: 40 / 70 mesh ceramsite, outer layer polyol resin, inner layer polyol resin, inner layer isocyanate resin, outer layer isocyanate resin, outer layer catalyst, inner layer catalyst and amine additives;

[0035] (2) Heating: heating the ceramsite in step (1) to 80-160°C;

[0036] (3) sand mixing: adding the ceramsite in step (2) into the mixing pot and mixing sand at a rotating speed of 70-100 rev / min;

[0037] (4) Film coating for the first time: add the inner layer polyol resin and inner layer catalyst in step (1) into the mixing casserole, and time it; when the temperature of the mixing casserole is lowered to 75-140 ℃, add step ( 1) the inner layer isocyanate resin;

[0038] (5) Second film coating: when the temperature of the mixing casserole drops to 55-110 °C, add the outer polyol resin and the outer layer catalyst; when the temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com