Combination conveying particle discharge machine

A discharge machine and granule technology, applied in the field of grain storage, can solve the problems of unimaginable consequences, high energy consumption, high labor intensity, etc., and achieve the effects of reducing labor costs, improving the safety of grain storage, and ensuring the broken rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

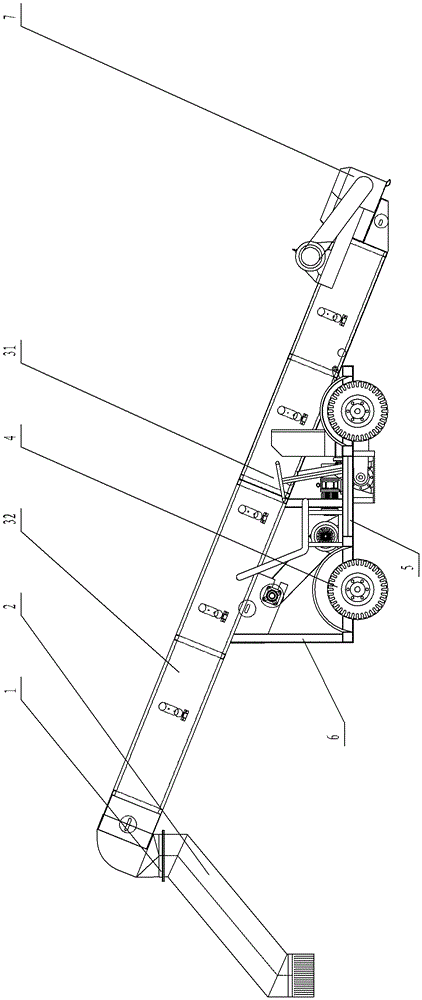

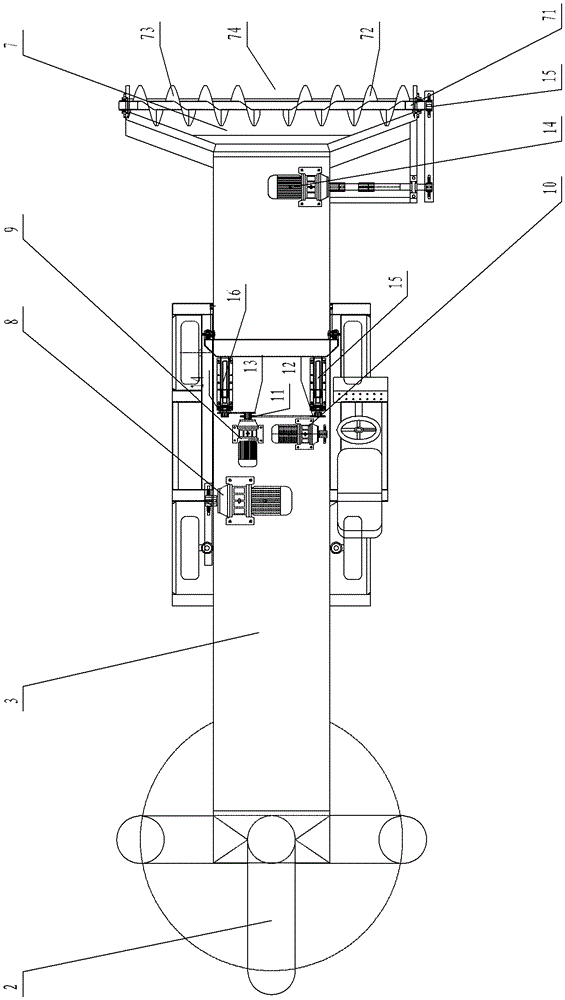

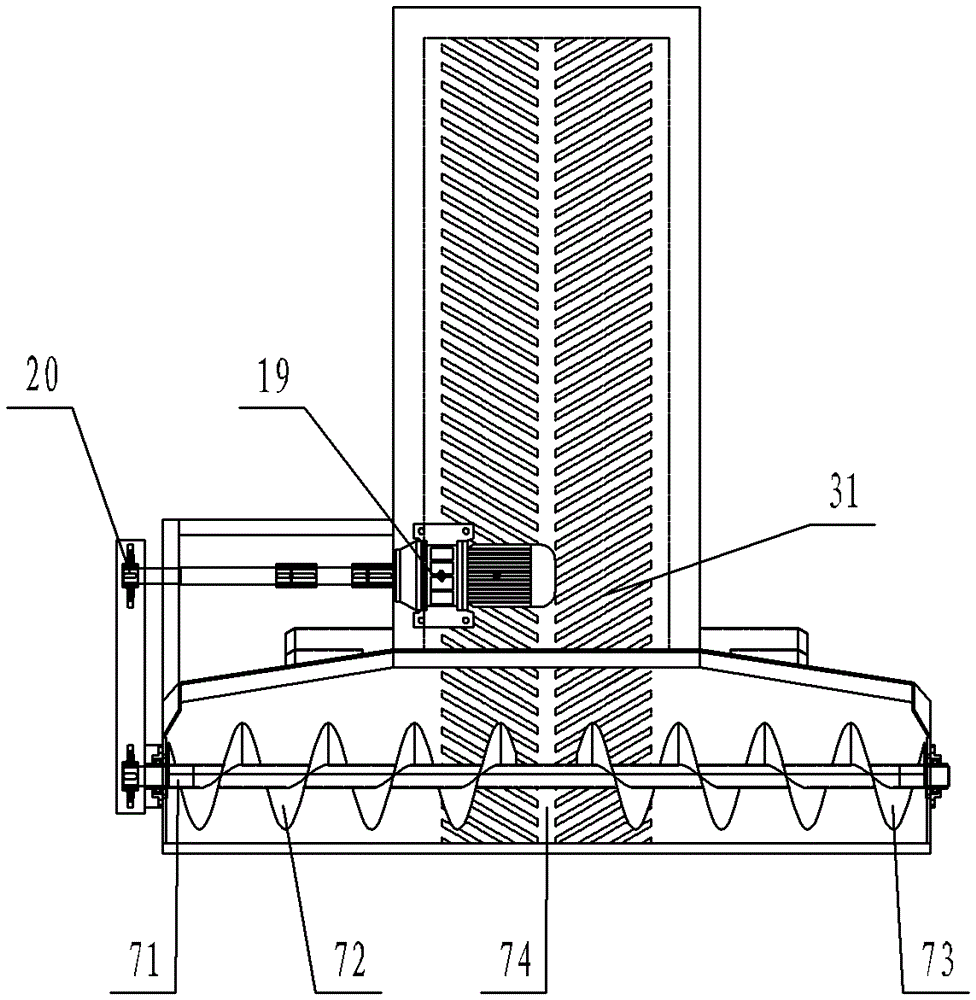

[0023] see Figure 1 ~ Figure 3 , is a structural schematic diagram of the combined conveying particle discharger involved in the present invention. Including a chassis 5, the chassis 5 is a frame structure, the trolley 5 is provided with a running wheel 4, and the rear end of the trolley 5 is provided with a support frame 6, and is connected with the inclined conveyor belt 3 through the support frame 6. The tail end of the conveyor belt 3 is connected to the discharge port 2 , and the front end of the conveyor belt 3 is connected to the shovel hopper 7 . The tail end and the front end are determined by the travel direction of the combined conveying particle discharger. The front end of the conveyor belt 3 is also the lower end, and the tail end of the conveyor belt 3 is also the higher end. The shovel hopper 7 is provided with a rotating shaft 71 , and both ends of the rotating shaft 71 are pivotally connected to the shovel hopper 7 . The rotating shaft 71 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com