Preprocessing method of glass bottle raw materials

A pre-processing, glass bottle technology, applied in the field of pottery or other ceramics, glass, can solve the problems of easy accidental injury to staff, low safety performance, glass slag splashing, etc., to increase melting efficiency, speed up melting speed, and improve safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

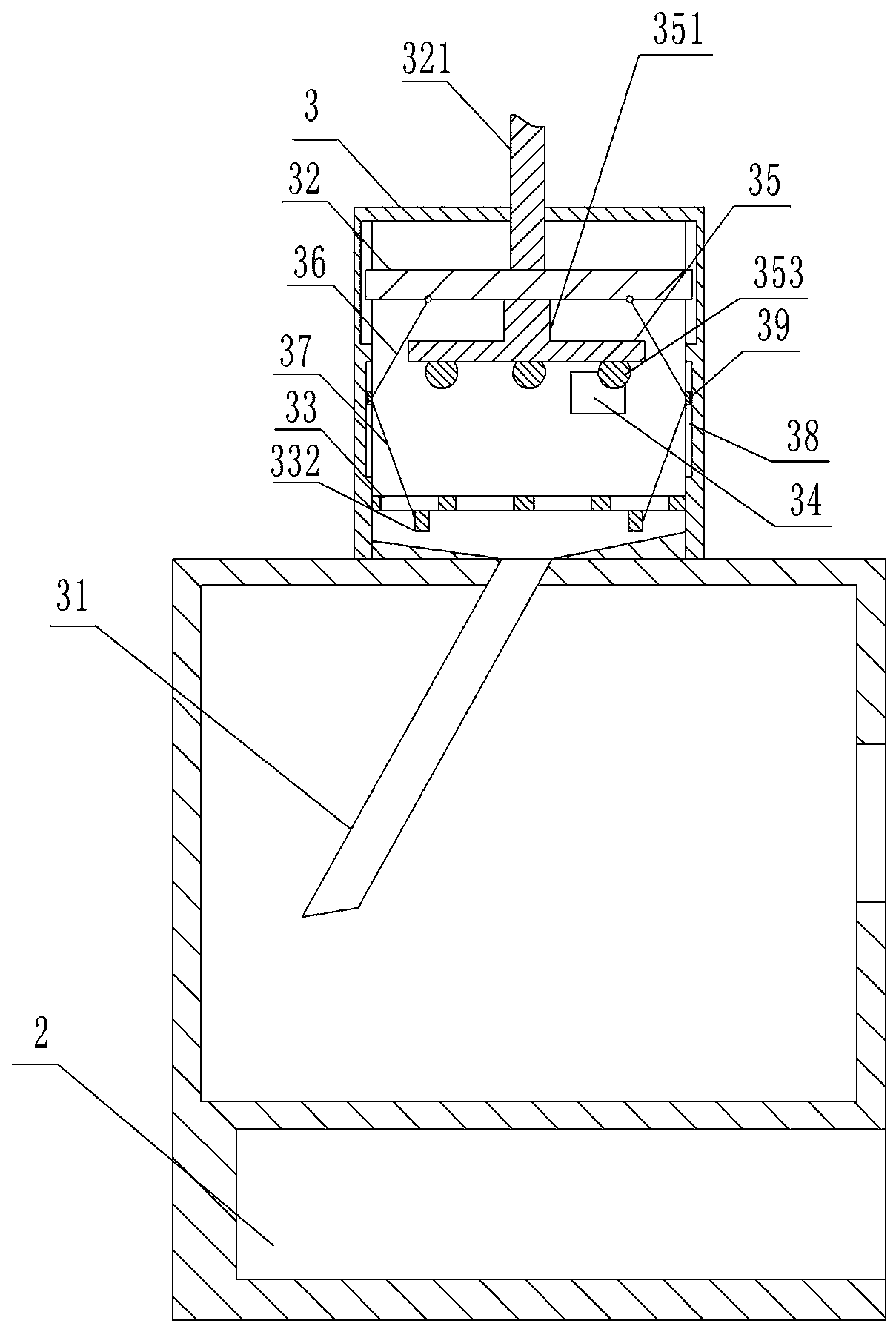

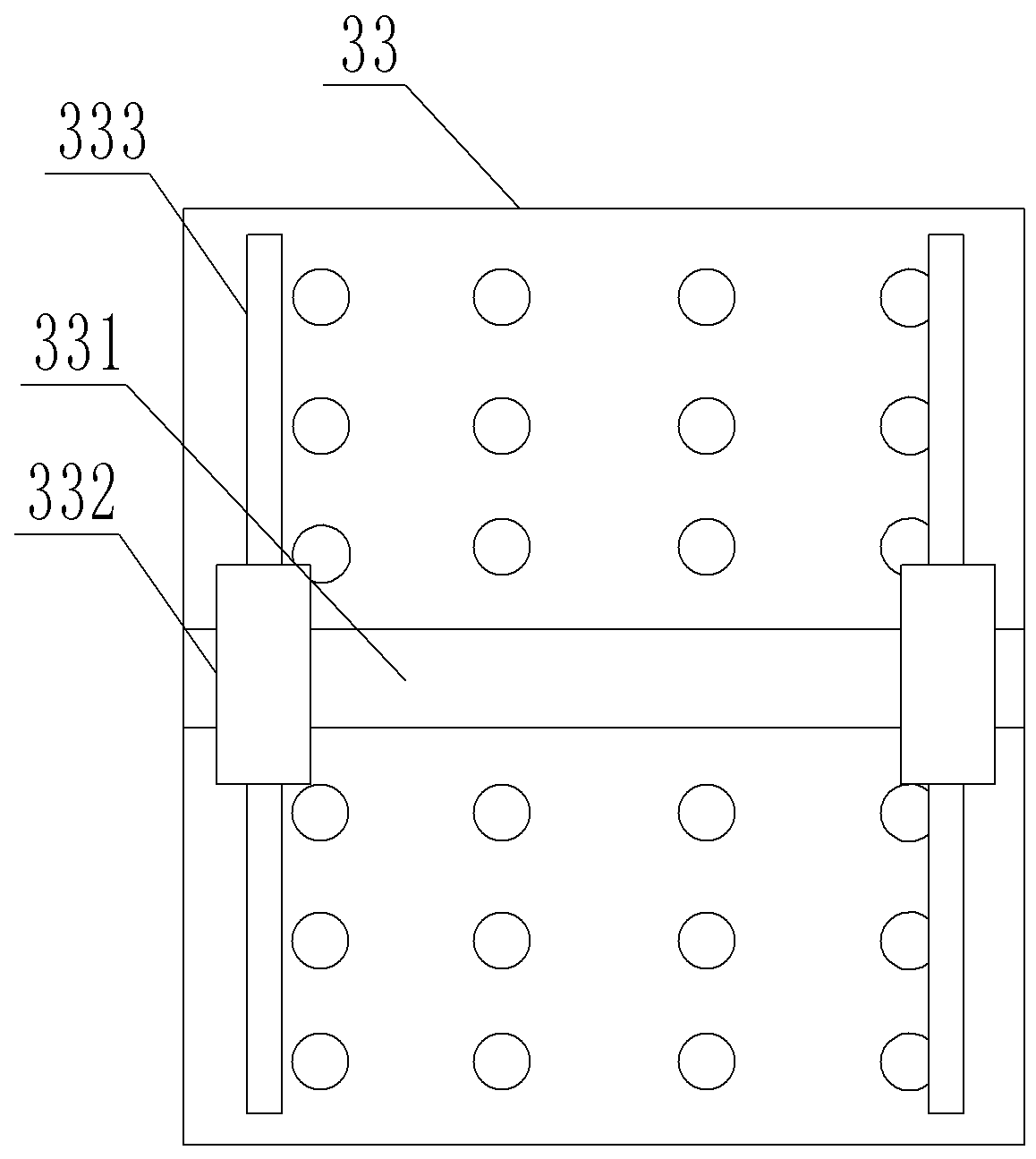

[0032] Such as figure 1As shown, the preprocessing method of glass bottle raw materials uses a melting furnace to preprocess the raw materials. The melting furnace includes a melting tank 1. The lower part of the melting tank 1 is provided with a heating part 2 for heating the melting tank 1; There is a power device and a feeding part for feeding into the melting tank 1; The feeding part includes a barrel 3 and a heat pipe 31, and the barrel 3 can be set to a circle or a square as required (the barrel 3 in this solution is a square), and the inside of the barrel 3 is a holding chamber for holding glass blocks One end of the heat pipe 31 is connected to the center of the bottom surface of the barrel 3, and the other end of the heat pipe 31 extends into the melting tank 1; One end is set at an angle. The inner bottom surface of the barrel 3 is a concave surface inclined toward the heat pipe 31 .

[0033] A piston 32 is slidably connected in the barrel 3, and the top surface o...

Embodiment 2

[0051] The difference between this embodiment and embodiment 1 is that the preprocessing method of the glass bottle raw material:

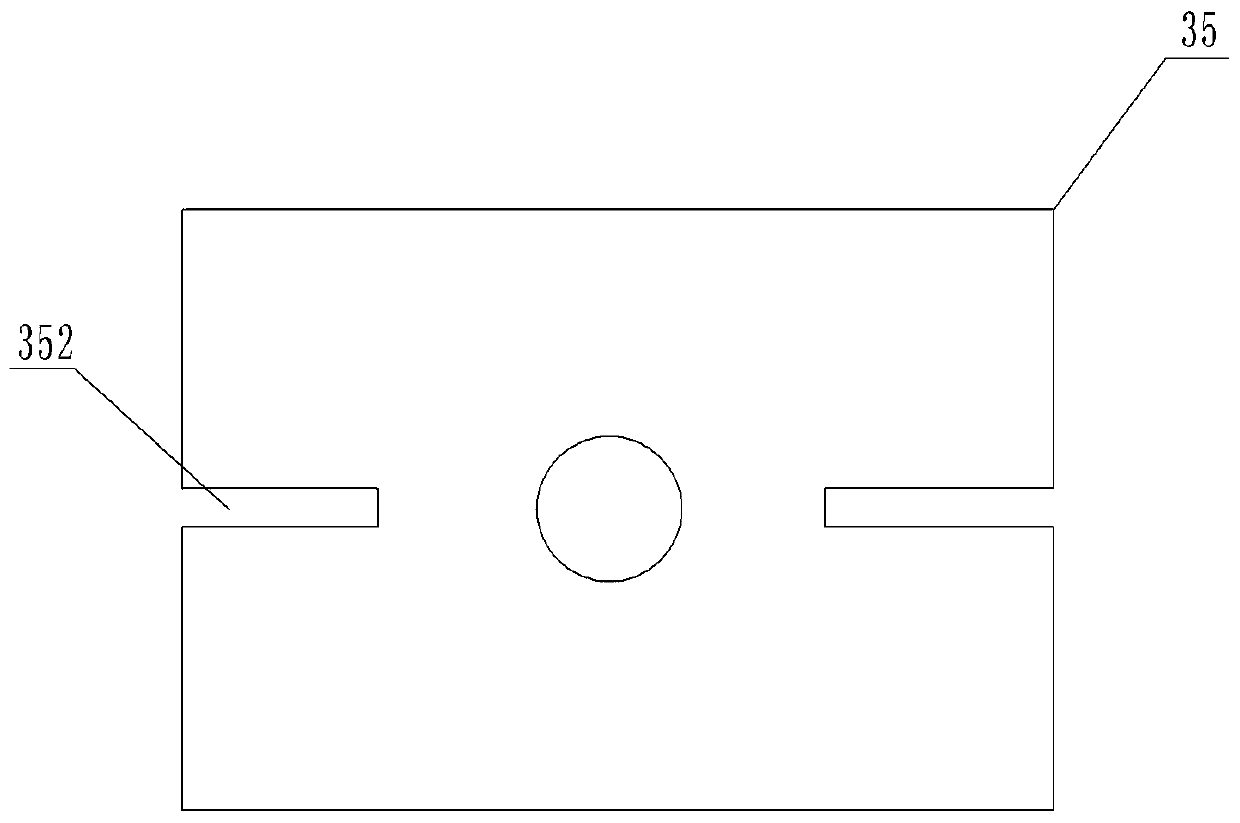

[0052] Step 1. Breaking for the first time: put the glass block into the barrel 3 from the feeding port 34, close the feeding port 34; after 30 minutes, start the power device, which drives the piston 32 to move downward; at the same time, the crushing plate 35 also moves downward Move until the steel ball 353 contacts the glass block, and squeeze the glass block to realize the first breaking of the glass block.

[0053] Step 2, secondary crushing: the power device drives the piston 32 to move upward, and at the same time the crushing plate 35 also moves upward, and the steel ball 353 leaves the glass block; when the temperature in the barrel 3 reaches 160°C, the power device drives the piston 32 to move downward, Simultaneously, the crushing plate 35 also moves downward until the steel ball 353 contacts the glass, and squeezes the glass to realiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com