Film covering proppant

A technology of proppant and film coating, which is applied in the direction of production fluid, wellbore/well components, drilling composition, etc., can solve the problems of high fracturing cost, non-self-suspension, reservoir damage, etc., and achieve low cost, Eliminate the liquid preparation process and equipment, and the effect of low drag reduction rate

Inactive Publication Date: 2019-01-04

CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

View PDF17 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The effect of the polyurethane resin used in the proppant coating is to increase the hardness of the proppant and reduce the fracture rate of the proppant, but this kind of proppant only meets the requirements of strength and ha

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

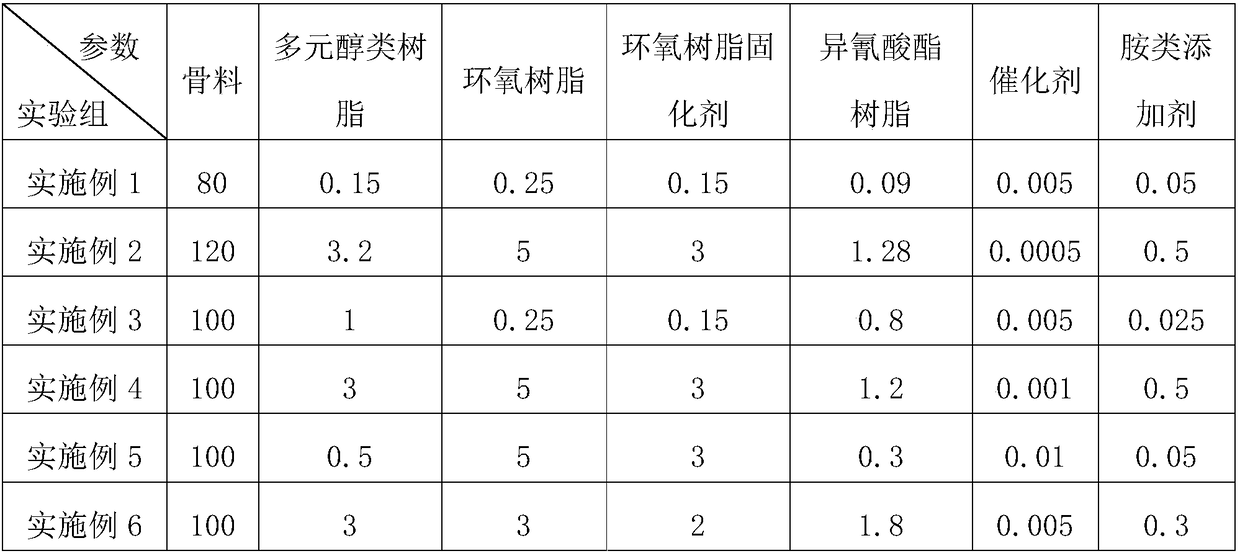

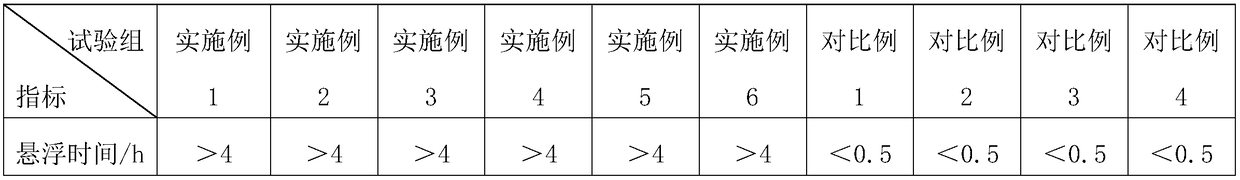

The invention belongs to the field of mixtures for hole drilling or well drilling and particularly discloses a film covering proppant. The film covering proppant comprises an aggregate and a resin layer for wrapping the aggregate; the resin layer is divided into an inner resin layer and an outer resin layer; the inner resin layer is synthesized from an inner layer synthetic material; the inner layer synthetic material comprises epoxy resin and an epoxy resin curing agent; the outer resin layer is synthesized from an outer layer synthetic material; the outer layer synthetic material comprises polyol resin, isocyanate resin, an amine additive and a catalyst, wherein the hydroxyl equivalent of the polyol resin is 60-300, and the mass fraction of the isocyanate resin is 2/5-4/5 of the polyol resin. The proppant can naturally suspend in clear water; while the fracturing index of a traditional proppant is satisfied, any thickening agent is not required to be added during the fracturing process, so that the fracturing cost is reduced, the fracturing process is simplified, and the environmental pollution is reduced.

Description

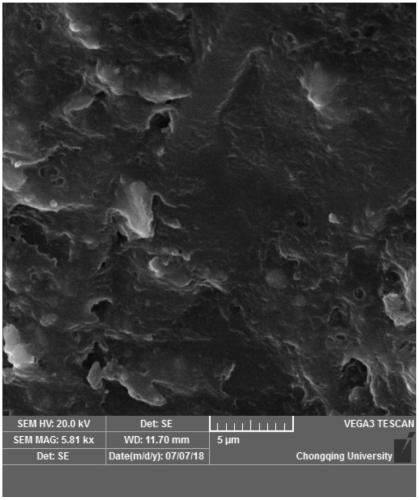

technical field [0001] The invention relates to the field of mixtures used for drilling or well drilling, in particular to a membrane-covered proppant. Background technique [0002] In order to develop deep oil and gas wells and increase production, hydraulic fracturing technology is widely used. Hydraulic fracturing technology is a technology that uses high-pressure pumps on the ground to continuously inject high-viscosity fracturing fluid into the oil well through the wellbore to form a high pressure in the lower part of the oil well. With the continuous injection of fracturing fluid, the pressure also continues to rise. When the tensile strength and formation stress of the formation rock near the wellbore wall are less than the pressure formed by the fracturing fluid, fractures will occur in the formation near the bottom of the well. When the fracturing fluid carrying proppant continues to be injected, the fractures in the rock formation will extend forward and be filled...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09K8/80C08G18/40

CPCC08G18/40C09K8/805

Inventor 熊帆熊鹰王正力陈秋庆

Owner CHONGQING CHANGJIANG RIVER MOLDING MATERIAL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com