A kind of pedot film with high film thickness and high conductivity and preparation method thereof

A high-conductivity, thin-film technology, used in equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, circuits, etc., can solve the problems of accelerated reaction speed, low solubility, pollution, etc. The effect of simplifying the process and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

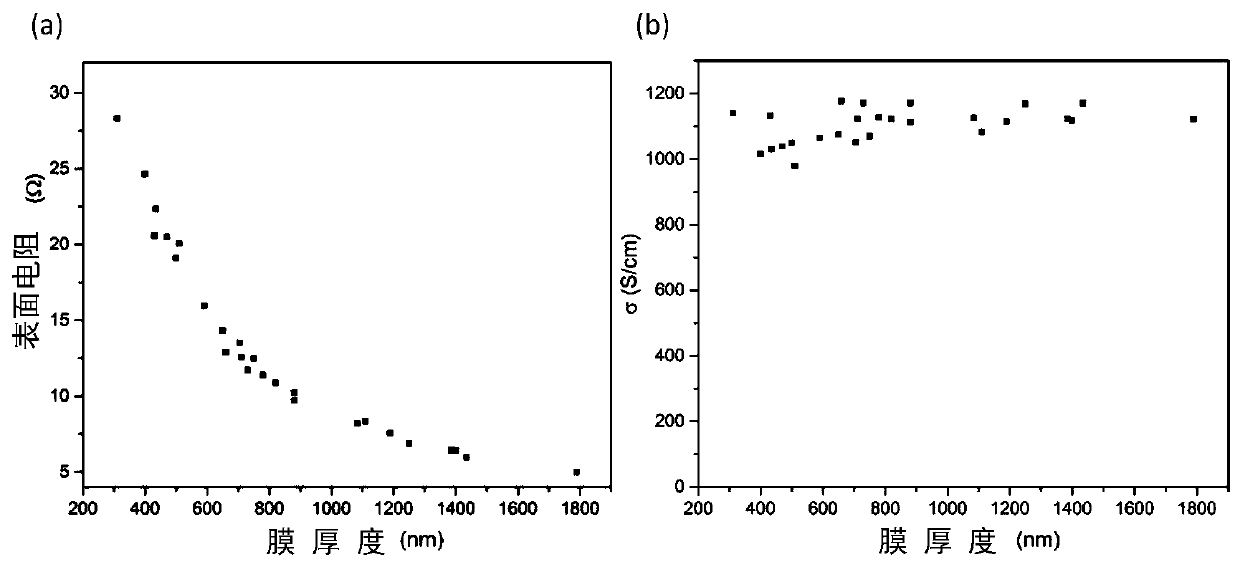

[0030] The present invention is prepared by synthesizing oxidant iron salt FeX 3 , Preparation of precursor solution, spin coating, polymerization, and washing processes. The invention can also effectively increase the film thickness and avoid the addition of pyridine and PEPG, while ensuring that the thermoelectric performance is not reduced.

[0031]The present invention uses doped ion sodium salt, barium salt or acid as raw material, reacts with ferric trichloride or ferric sulfate, prepares oxidant iron salt by barium sulfate precipitation method, hydrogen chloride distillation method or solution precipitation method, and then its Soluble in alcohol solvent. The solvent can be one or more of methanol, ethanol, propanol, butanol or alcohol-water mixed medium, and the concentration is between 46%-84% by mass fraction. The PEDOT synthesized based on the method provided by the present invention can be synthesized in methanol, ethanol, propanol, butanol or alcohol-water mixed...

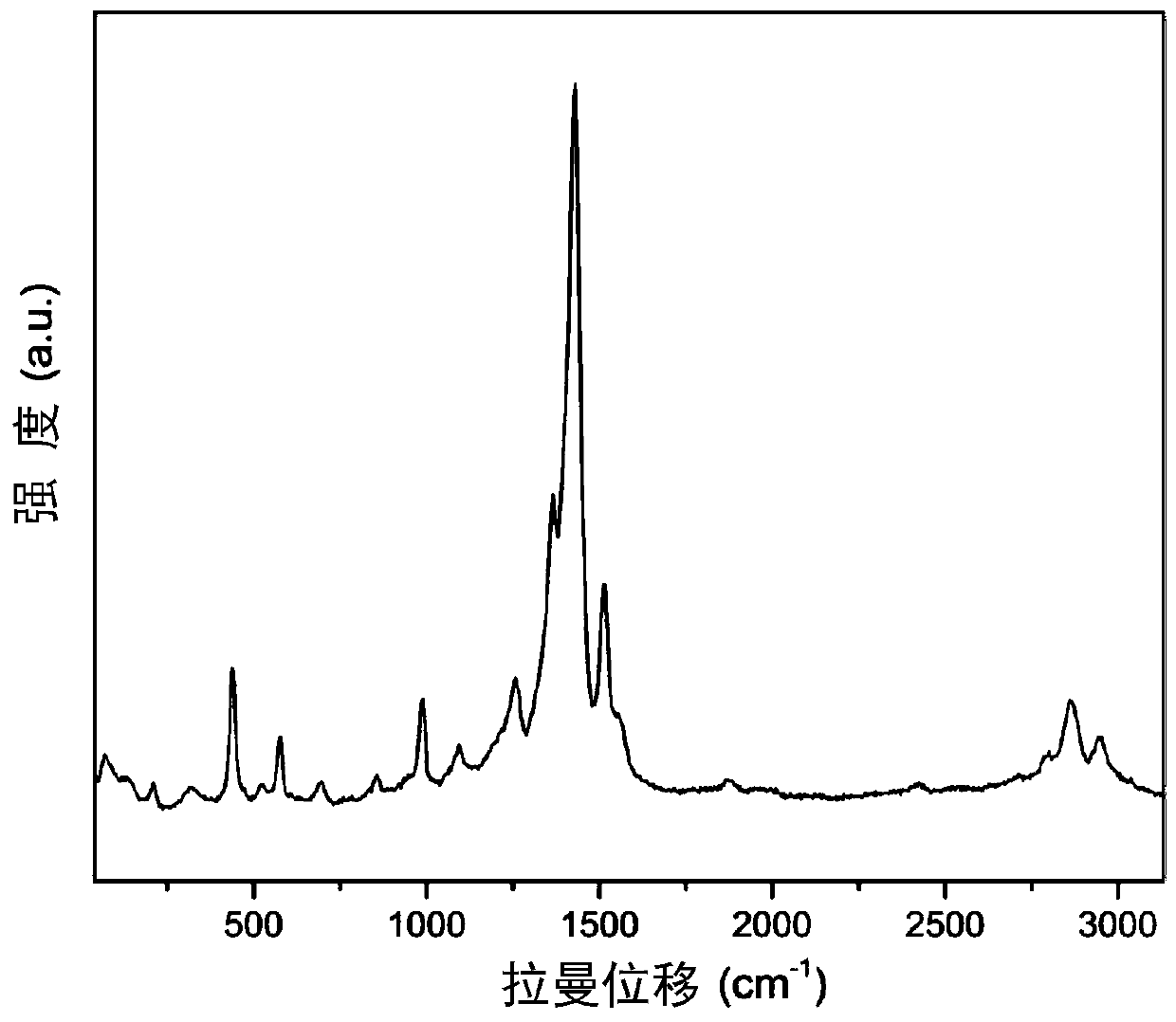

Embodiment 1

[0041] Embodiment 1PEDOT: dodecylbenzenesulfonic acid (PEDOT: DBSA) material

[0042] Dissolve 9.00mmol ferric chloride hexahydrate and 18.00mmol sodium dodecylbenzenesulfonate in deionized water respectively, and add the ferric chloride solution dropwise to the sodium dodecylbenzenesulfonate solution under vigorous stirring , the iron dodecylbenzenesulfonate precipitate was washed 10 times with deionized water until no Cl - Check out. Then add 250mL ethanol to dissolve and evaporate to dryness in a rotary evaporator. Then re-dissolve the solid in ethanol to prepare an ethanol solution with a mass fraction of 74.3%-83.1% for future use. The above solution was spin-coated on a 18*18mm soda-lime glass substrate to form a film at a rotation speed of 5000-10000rpm and a spin-coating time of 15s. Place the spin-coated ferric dodecylbenzenesulfonate film in a double-pass flat-bottomed reaction vessel made of quartz or glass, feed nitrogen and saturated EDOT monomer vapor with a g...

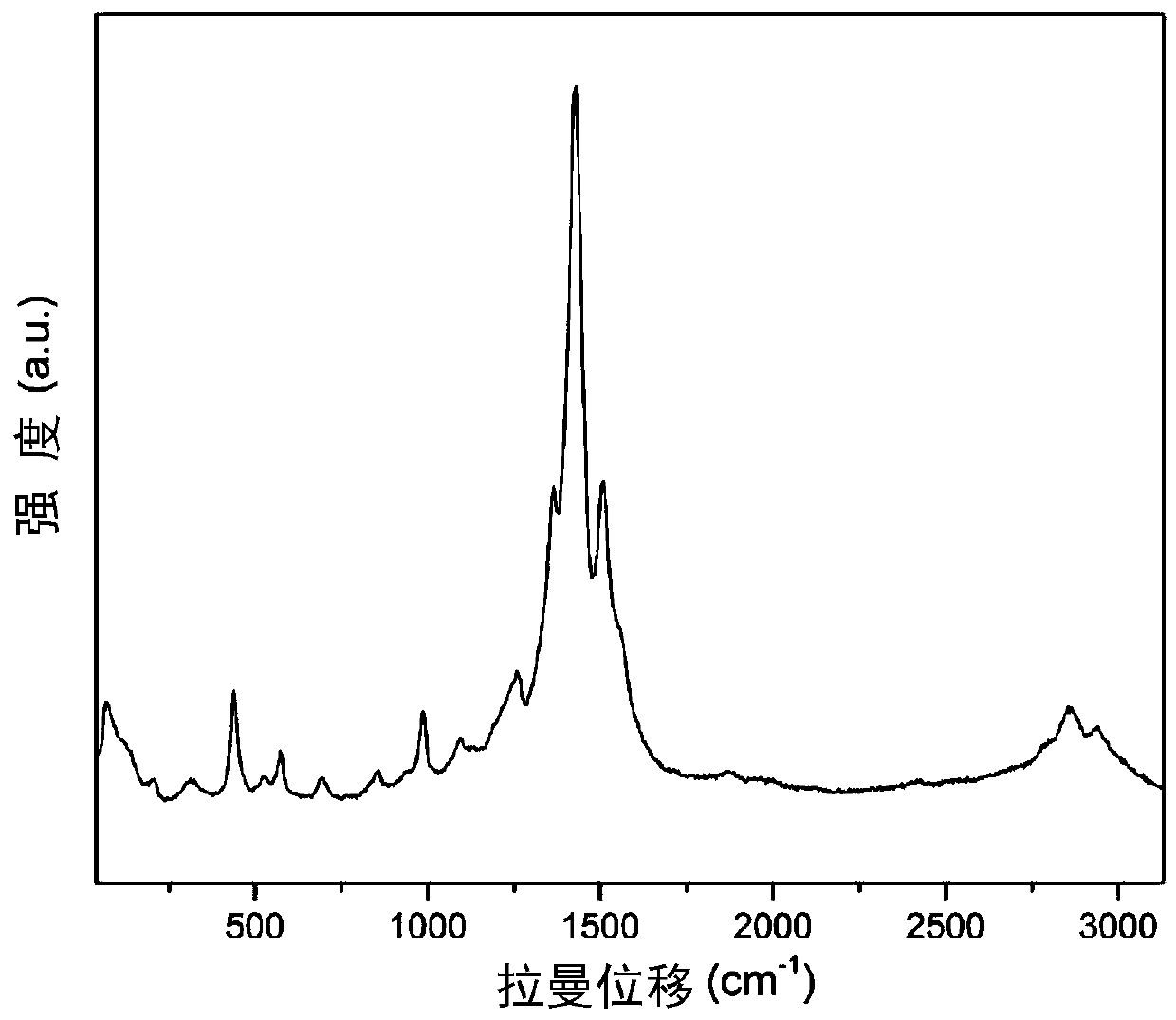

Embodiment 2

[0043] Embodiment 2PEDOT: butyl naphthalene sulfonic acid (PEDOT: BNSA) material

[0044] Dissolve 9.00mmol ferric chloride hexahydrate and 18.00mmol sodium butylnaphthalene sulfonate in deionized water respectively, add the ferric chloride solution dropwise into the sodium butylnaphthalene sulfonate solution under vigorous stirring, and The ferric naphthalenesulfonate precipitate was washed 10 times with deionized water until no Cl ions were detected. Then add 250mL ethanol to dissolve and evaporate to dryness in a rotary evaporator. Then the solid was re-dissolved in ethanol to prepare an 80.1% mass fraction ethanol solution for later use, and then 5% mass fraction of butylnaphthalenesulfonic acid was added. The above solution was spin-coated on a 18*18mm soda-lime glass substrate to form a film at a rotation speed of 6000rpm and a spin-coating time of 15s. Place the spin-coated precursor film in a double-pass flat-bottomed reaction vessel made of quartz or glass, pass thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com