Adjusting device and adjusting method for cereal threshing cylinder concave clearance

A concave plate gap adjustment and threshing drum technology, which is applied in threshing equipment, applications, agricultural machinery and implements, etc. Plate gap and other issues, to achieve the effect of improving work reliability and work efficiency, improving threshing separation performance, and good follow-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation process of a specific model of a grain threshing drum concave plate gap automatic adjustment device and adjustment method of the present invention will be further described below in conjunction with the accompanying drawings.

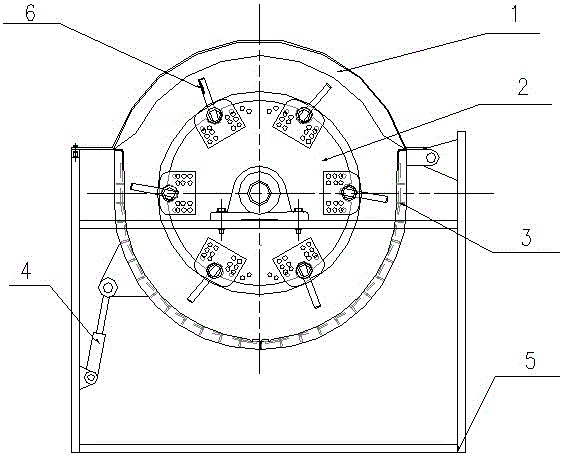

[0026] Such as figure 1 As shown, a grain threshing drum concave plate gap automatic adjustment device and adjustment method, including a top cover 1, threshing drum 2, concave screen 3, drive motor 4, frame 5, threshing tooth stress testing system 6 and signal receiving and processing system 7;

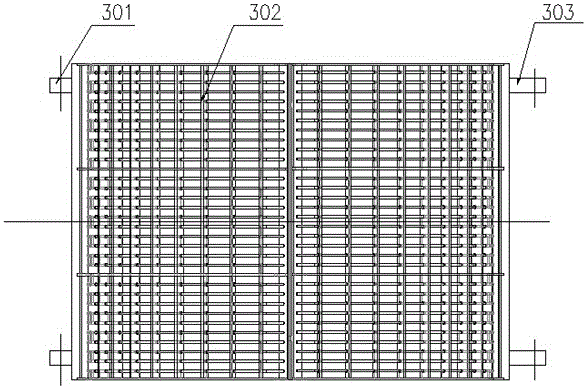

[0027] Such as figure 2 As shown, the concave plate sieve 3 is composed of a left hinged ear 301, a screen body 302, and a right hinged ear 303; the left hinged ear 301 is hinged with the right end of the drive motor 4, and the right hinged ear 303 is hinged with the frame 5. The adjustment range is 10~50mm.

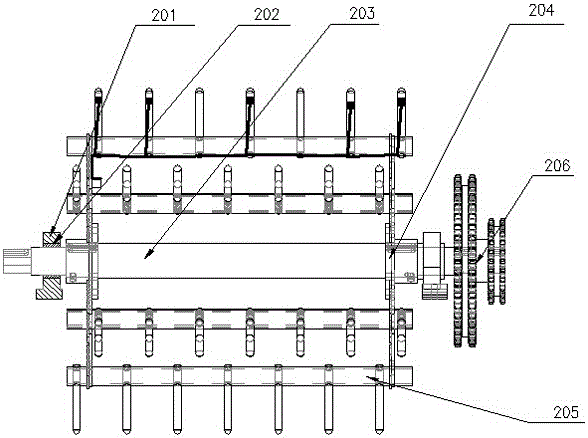

[0028] Such as image 3 As shown, the threshing drum 2 is composed of a bearing seat 201, a bearing 202, a trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com