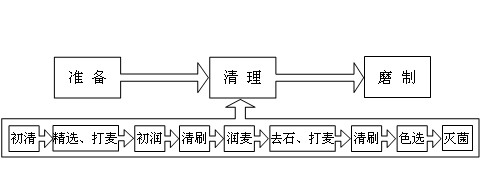

Wheat flour cleaning production process

A technology for cleaner production and wheat flour, applied in application, grain processing, agriculture, etc., can solve the problems of lack of effective technical means and insufficient attention to product quality and safety control, and achieve the effect of ensuring quality, low production cost and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

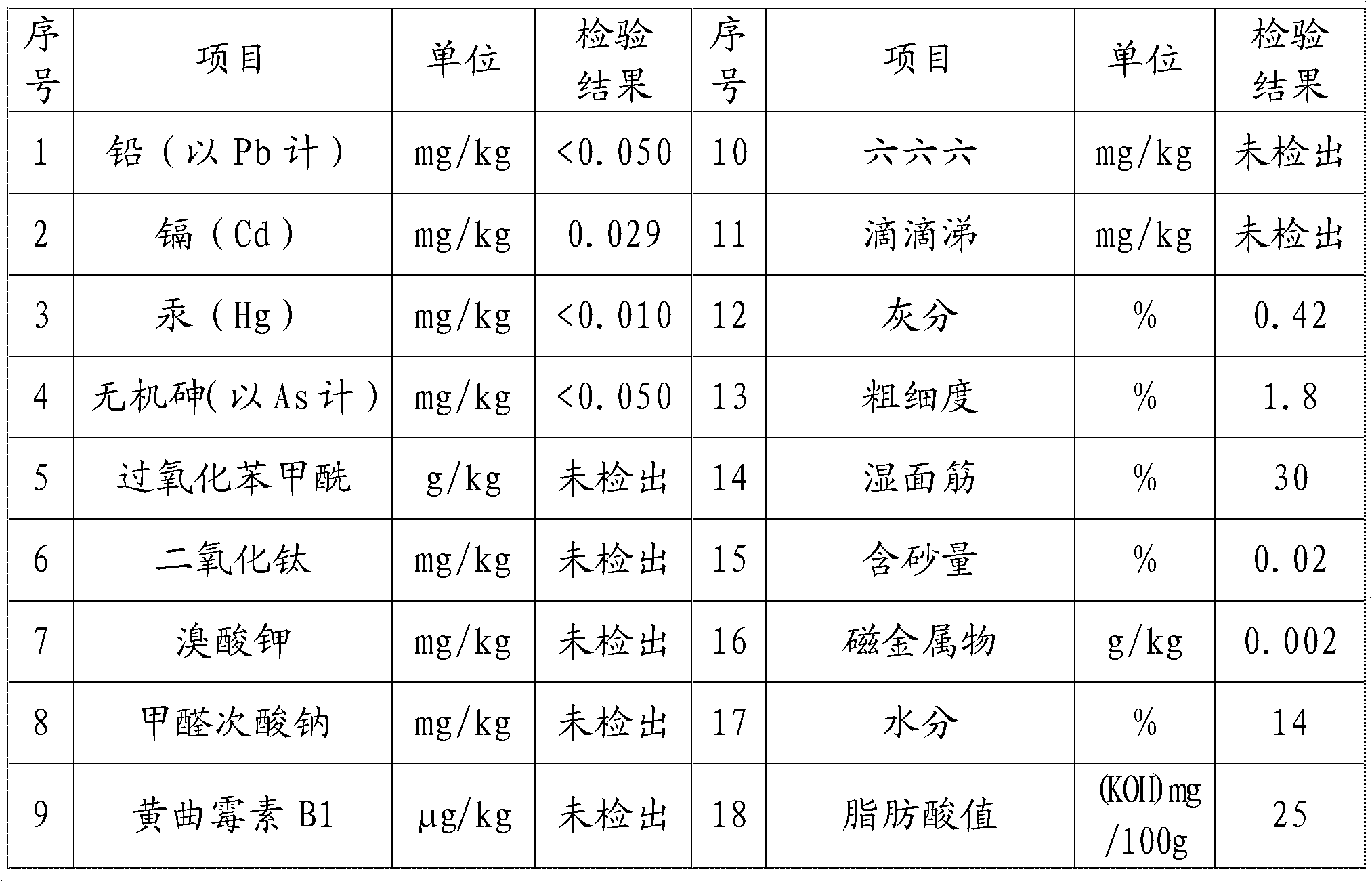

Embodiment 1

[0038] Different pasta foods have very different requirements for the quality of wheat flour. For example, bread is mainly produced with high-gluten wheat flour, while noodles, steamed bread, dumplings and other steamed noodles are mainly produced with wheat flour as raw materials to make biscuits. It is mainly produced with low-gluten wheat flour as a raw material, and the present invention adopts the wheat blending and flour blending technology of off-line blending and online blending, and the production of various special flours is treated differently. Because the finished wheat flour cannot be washed, and during the growth, harvesting, transportation and storage of the wheat, the wheat contains a variety of inorganic and organic impurities, as well as pesticide residues (residual poisons), chemical residues (residual poisons), mildew, and Disease-type microorganisms are difficult to remove by a single process. However, various toxins that can cause acute and chronic poisoni...

Embodiment 2

[0064] The process method of this embodiment is basically similar to the first embodiment, the difference is: in the first embodiment, the water source used in each step of B. cleaning and C. pulverizing is deep well water or deionized water, and passes The multi-media filter (produced by Henan Chunyi Water Treatment Equipment Co., Ltd., JDL series) filters, removes suspended solids, colloids, silt, clay, corrosives, particulates, organic matter, heavy metals, pigments and other impurities in the water body, and reduces water Turbidity, to achieve clarification of water quality, reduce the ash content of wheat flour by at least 0.11% to further improve the cleanliness of the finished wheat flour.

Embodiment 3

[0066] The process method of this embodiment is basically similar to that of the first embodiment. The difference is: in the first embodiment, the stable chlorine dioxide and activator (citric acid, maleic acid, Acid, lactic acid), that is, activated stable chlorine dioxide solution, in which the concentration of stable chlorine dioxide is 10-100mg / L, and the ratio of mass parts of stable chlorine dioxide to activator is 5-15:1 . Activated stable chlorine dioxide is recognized internationally as a new generation of mature high-efficiency, broad-spectrum and safe sterilization and disinfectant. It has been listed as a Class A high-efficiency and safe sterilization and disinfection by the World Health Organization (WHO), which can kill viruses , Bacteria, protists, algae, fungi and various spores and spore-forming bacteria, and can control the production of "three causing substances" (carcinogenic, teratogenic, mutagenic) in edible water. The use of activated stable chlorine dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com