Box-type formula technology of tobacco threshing and redrying production line

A technology of threshing and redrying and production line, which is applied to tobacco, tobacco preparation, storage device, etc., can solve the problems of long storage time, difficult handling of tailings, and reduced processing index, and achieves improved uniformity, improved uniformity and precision. The effect of formula production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

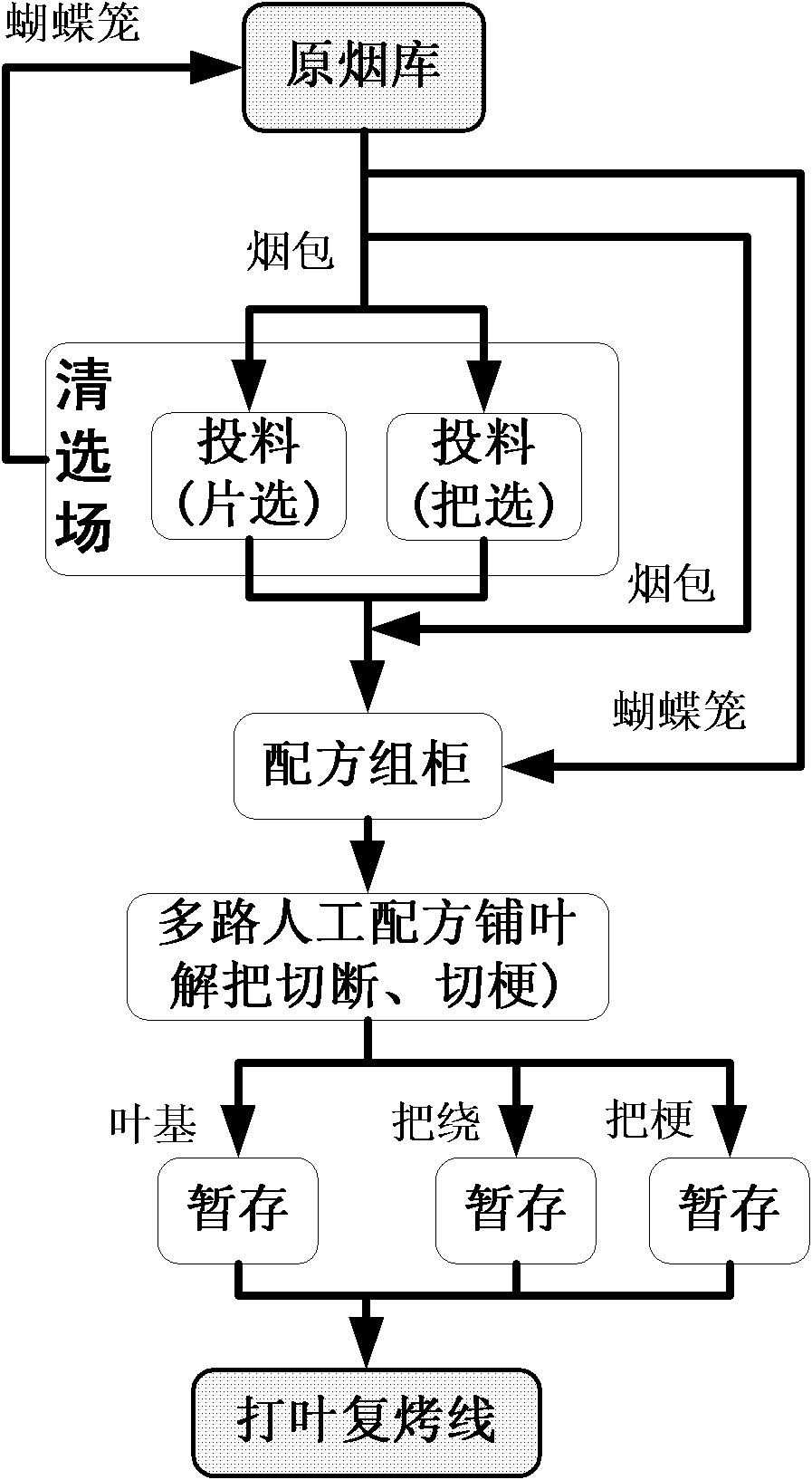

[0044] A box-type formula process of a tobacco threshing and redrying production line, such as Figure 4 As shown, the following process steps are included:

[0045] For the threshing and redrying production line with a processing capacity of 6000Kg / h, the formula modulus is 6000kg, and the rated value of the standard cage is 200kg / box.

[0046] 1. Feeding and packing;

[0047] Raw tobacco leaves of various types, flavors, origins, and grades are taken out from the original tobacco warehouse, and can enter the cleaning field for hand selection or sheet selection as required.

[0048] When the formula ratio is not known, a single-variety boxing method can be adopted, that is, the tobacco leaves that are selected or selected are measured and packed in a single-variety manner, and the full material box and tailing material box formed can be calculated according to It is necessary to choose to put in storage for temporary storage or return to the raw material warehouse for stora...

Embodiment 2

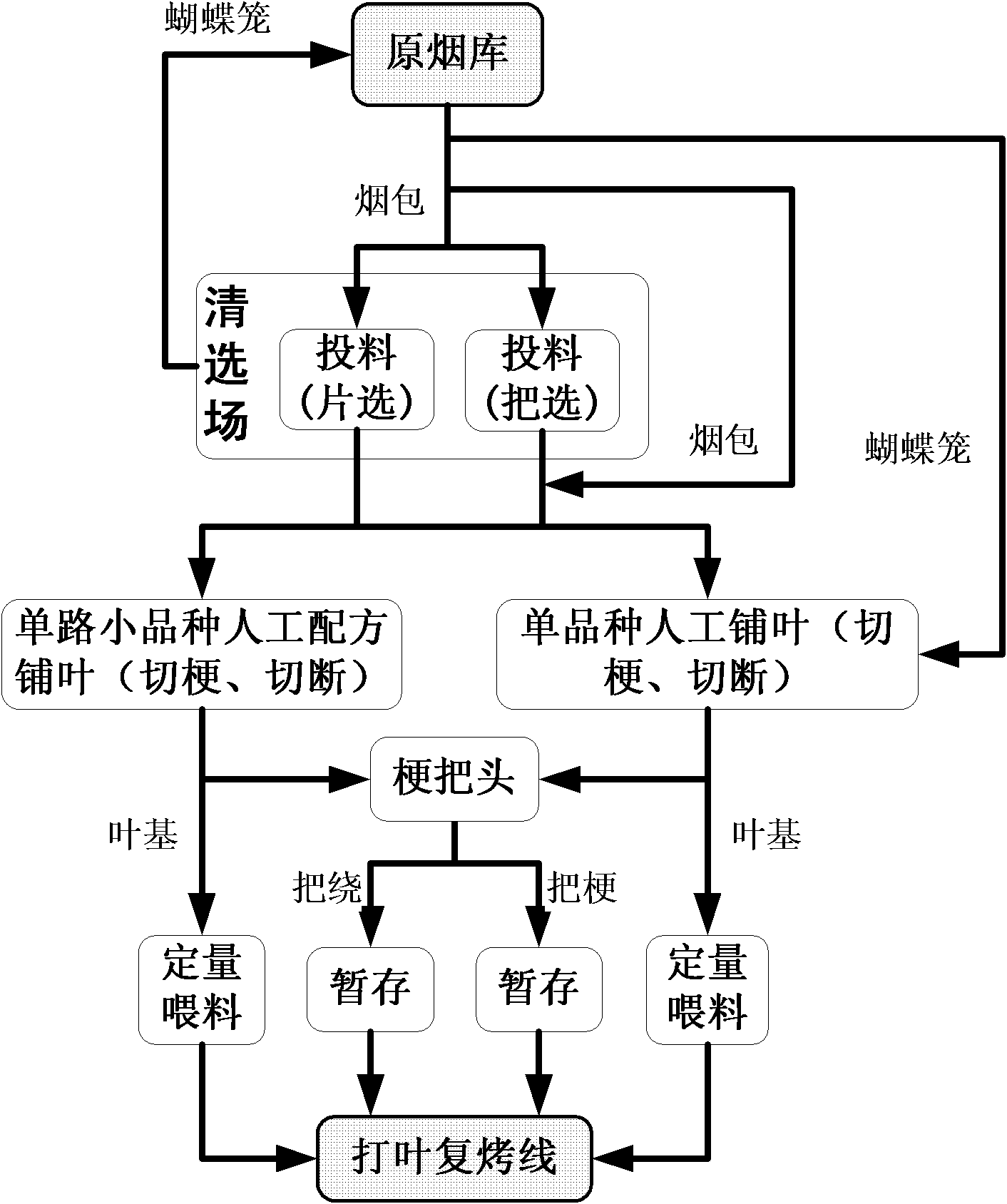

[0075] A box-type formula process of a tobacco threshing and redrying production line, such as Figure 4 As shown, the following process steps are included:

[0076] For the threshing and redrying production line with a processing capacity of 12000Kg / h, the formula modulus is 12000kg, and the rated value of the standard cage is 300kg / box.

[0077] 1. Feeding and packing;

[0078] Raw tobacco leaves of various types, flavors, origins, and grades are taken out from the original tobacco warehouse, and can enter the cleaning field for hand selection or sheet selection as required. Then you can choose to untie or cut off the treatment.

[0079] For the tobacco leaves whose formula ratio is not known at this time, the single-variety metering and boxing method is used for metering and boxing, and then sent to the temporary storage area of the cigarette box for temporary storage, and can also be returned to the original tobacco warehouse for storage as needed.

[0080] For the to...

Embodiment 3

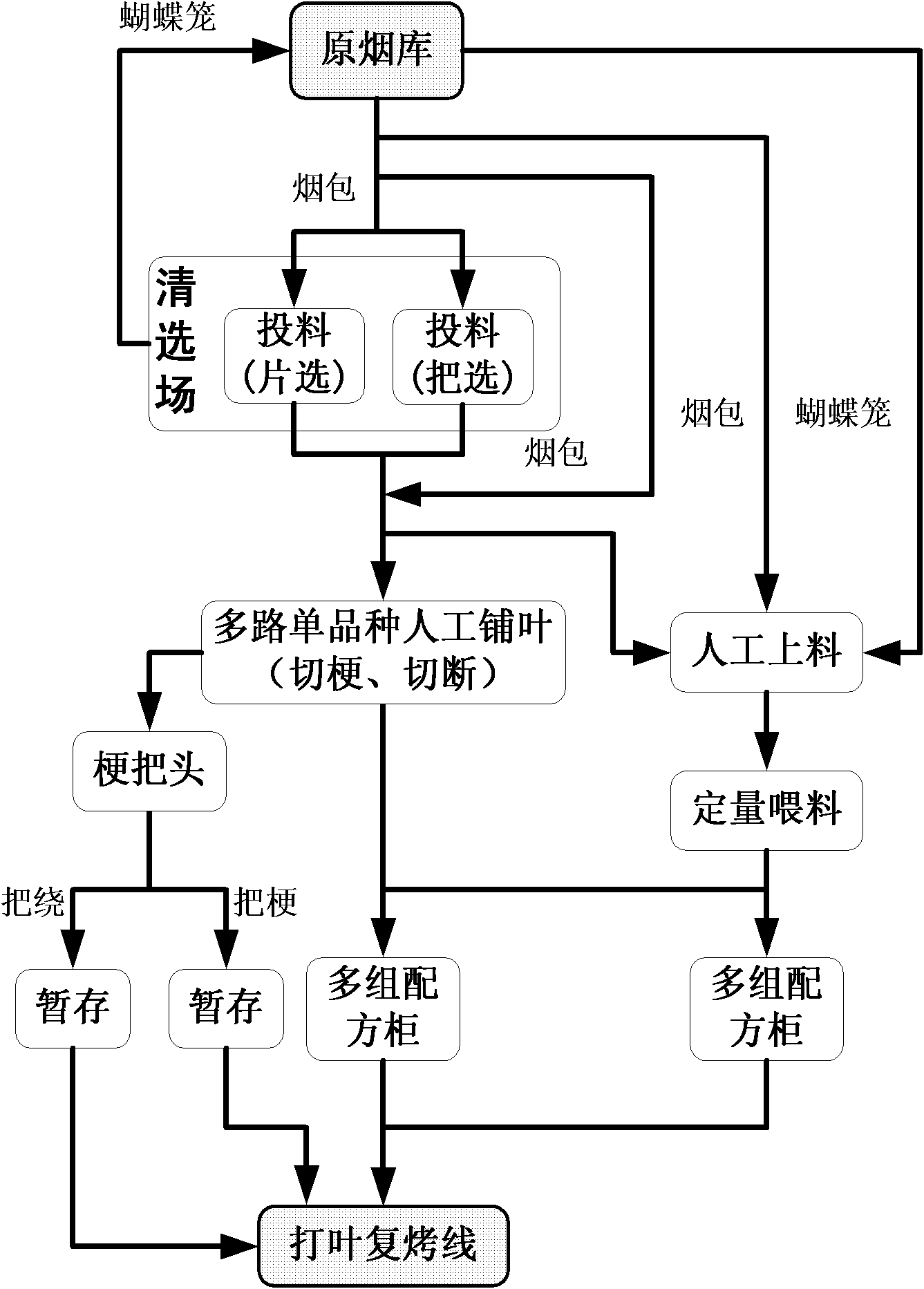

[0095] A box-type formula process of a tobacco threshing and redrying production line, such as Figure 4 As shown, the following process steps are included:

[0096] For the threshing and redrying production line with a processing capacity of 8000Kg / h, the formula modulus is 8000kg, and the rated value of the standard cage is 200kg / box.

[0097] 1. Feeding and packing;

[0098] Raw tobacco leaves of various types, flavors, origins, and grades are taken out from the original tobacco warehouse, and can enter the cleaning field for hand selection or sheet selection as required.

[0099] For the tobacco leaves whose formula ratio is not known at this time, the method of single-variety metering and boxing is used for metering and boxing, and then sent to the temporary storage area of the cigarette box for temporary storage, and can also be returned to the original tobacco warehouse for storage as needed. The storage mode in the temporary storage area is the same as that in Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com