Encapsulating method of blue-light LED chip

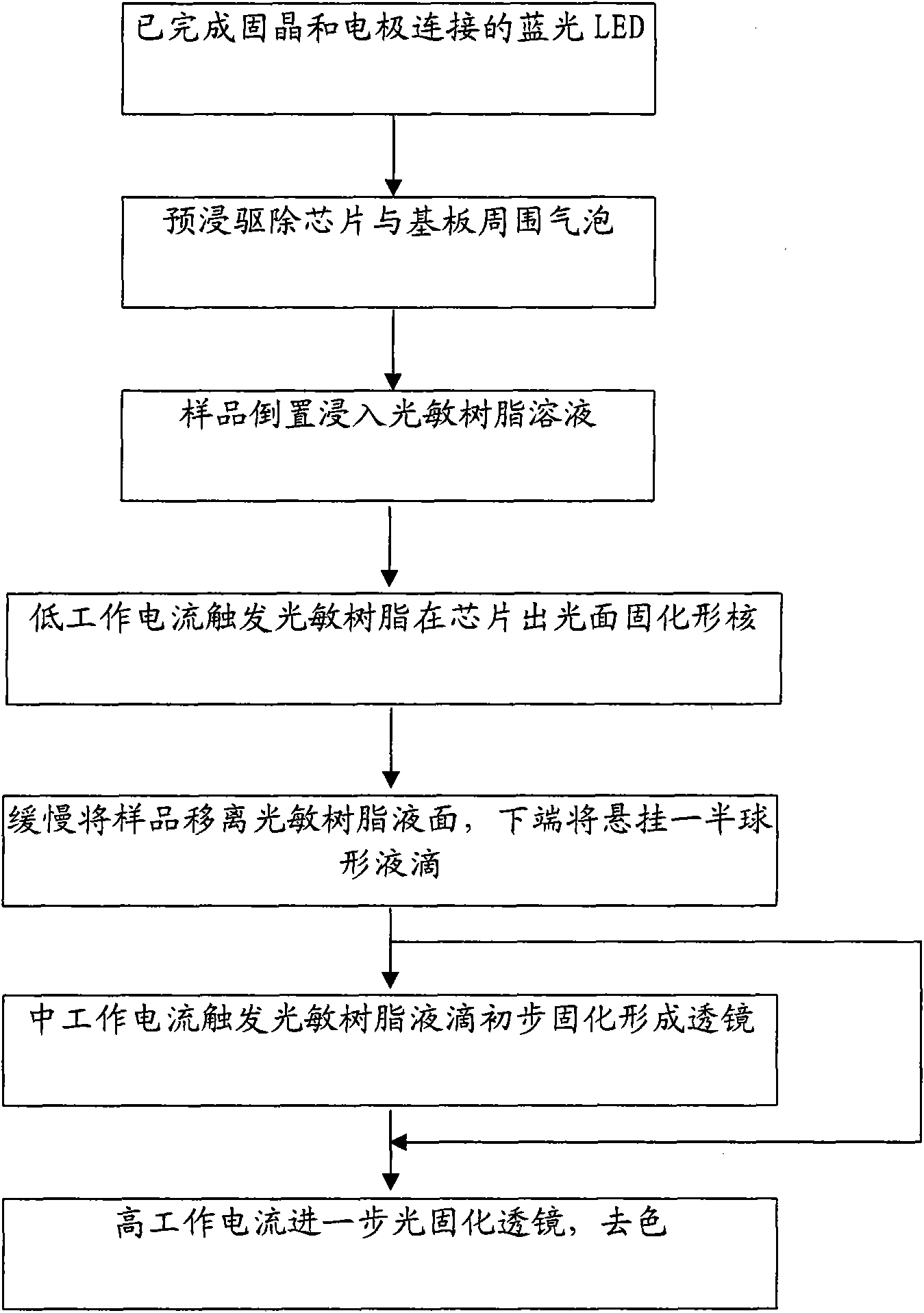

A technology of LED chip and packaging method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of many processes, high cost, and low production efficiency, and achieve high process repeatability, short production time, and high packaging efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

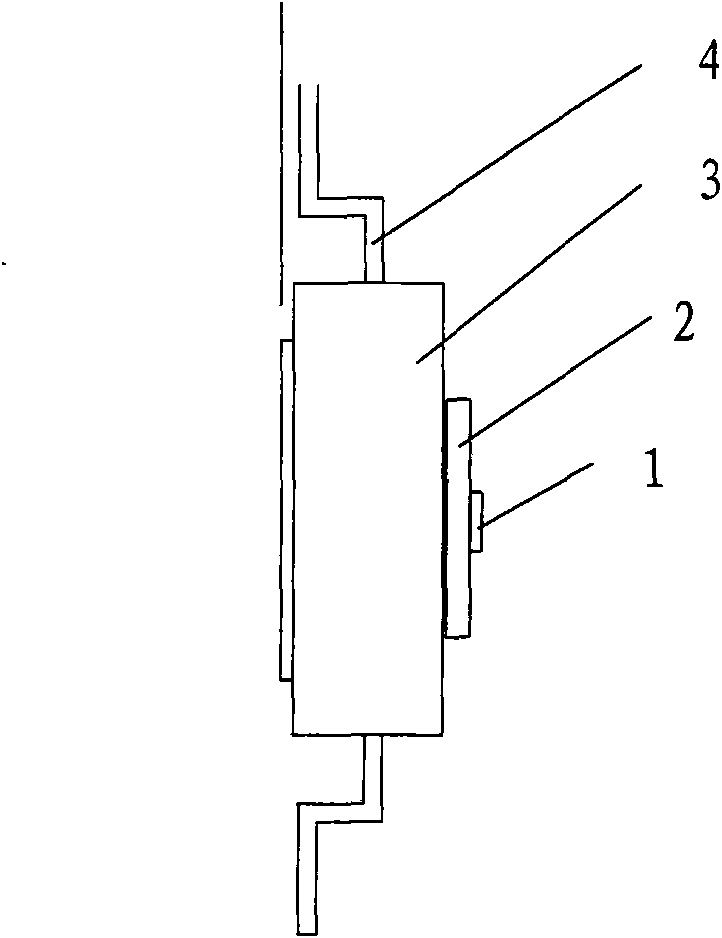

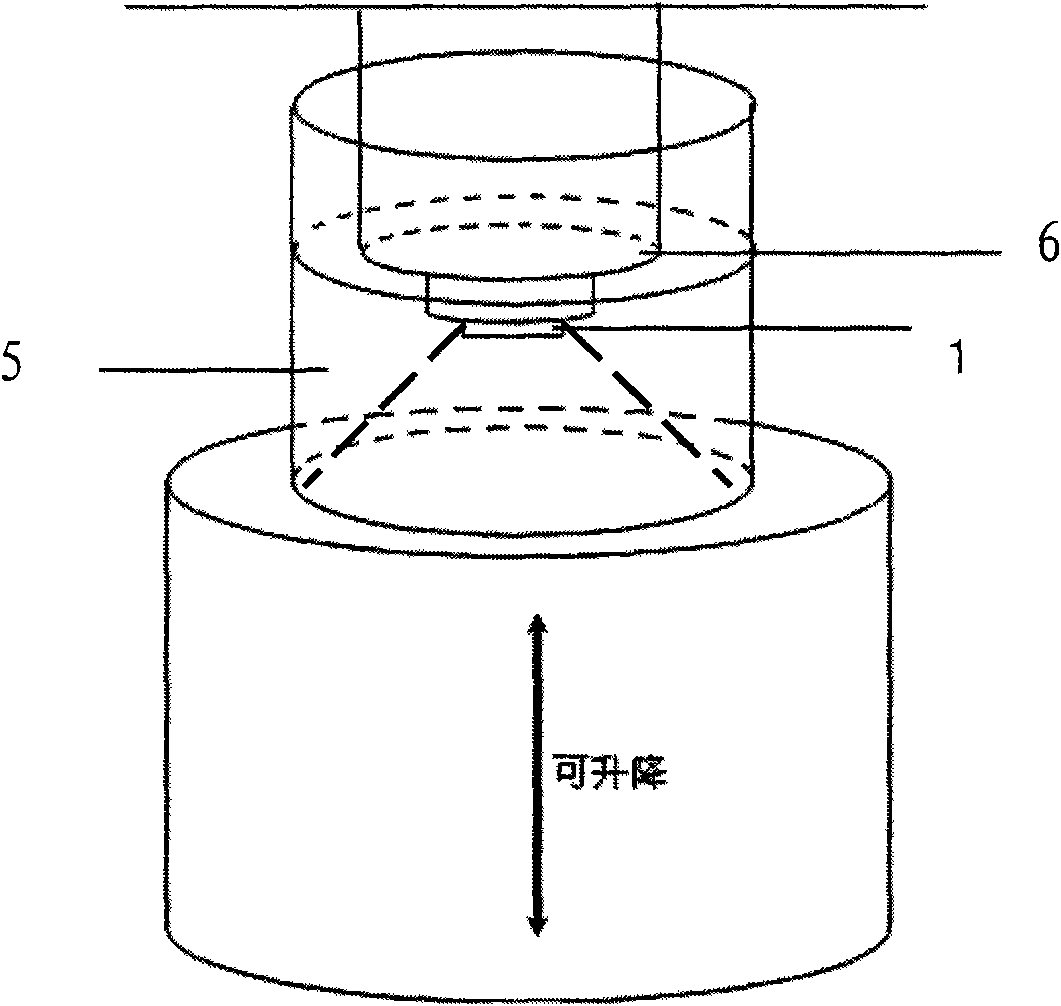

Examples

Embodiment

[0047] Example product test report

[0048] Compare the light color parameters before and after packaging:

[0049] Luminous flux increased from 7.511m before encapsulation to 9.211m after encapsulation;

[0050] Luminous efficacy increased from 6.99lm / w before packaging to 8.821m / w after packaging;

[0051] Optical radiation power increased from 169.09mW before packaging to 208.54mW after packaging;

[0052] The data of color rendering index, dominant wavelength, color purity, peak wavelength, and average wavelength remain unchanged.

[0053] It can be seen that this encapsulation method can effectively improve the indices of luminous flux, luminous efficiency, and radiant power by more than 20%. Moreover, the color rendering, dominant wavelength, color purity, peak wavelength, and average wavelength of the light emitted by the chip can be kept unchanged. This shows that this active packaging method can effectively improve the performance of blue LED chips.

[0054] The ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com