Compression, cutting, forming and automatic packing device for biomass fuel

A technology of biomass fuel and encapsulation device, which is applied in the direction of material molding presses, packaging, presses, etc., can solve the problems of no encapsulation machinery, etc., and achieve the effect of high encapsulation efficiency and good tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

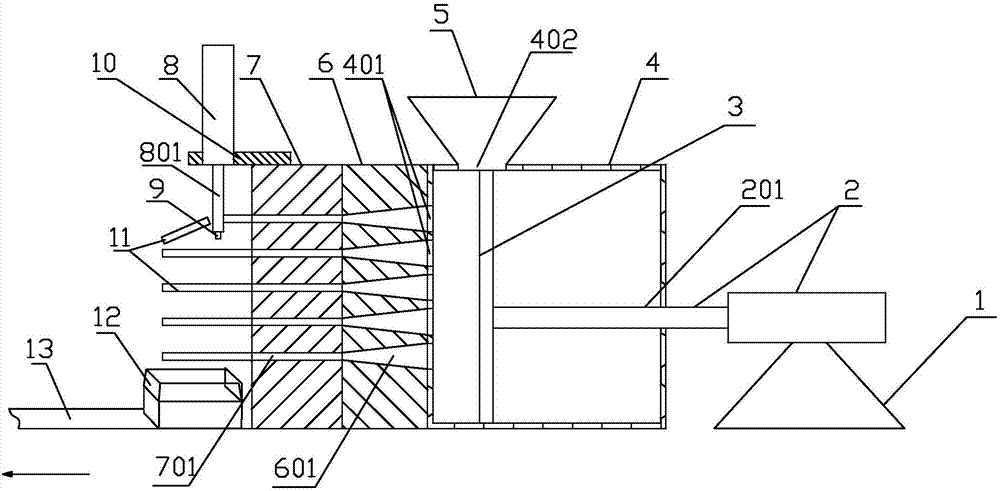

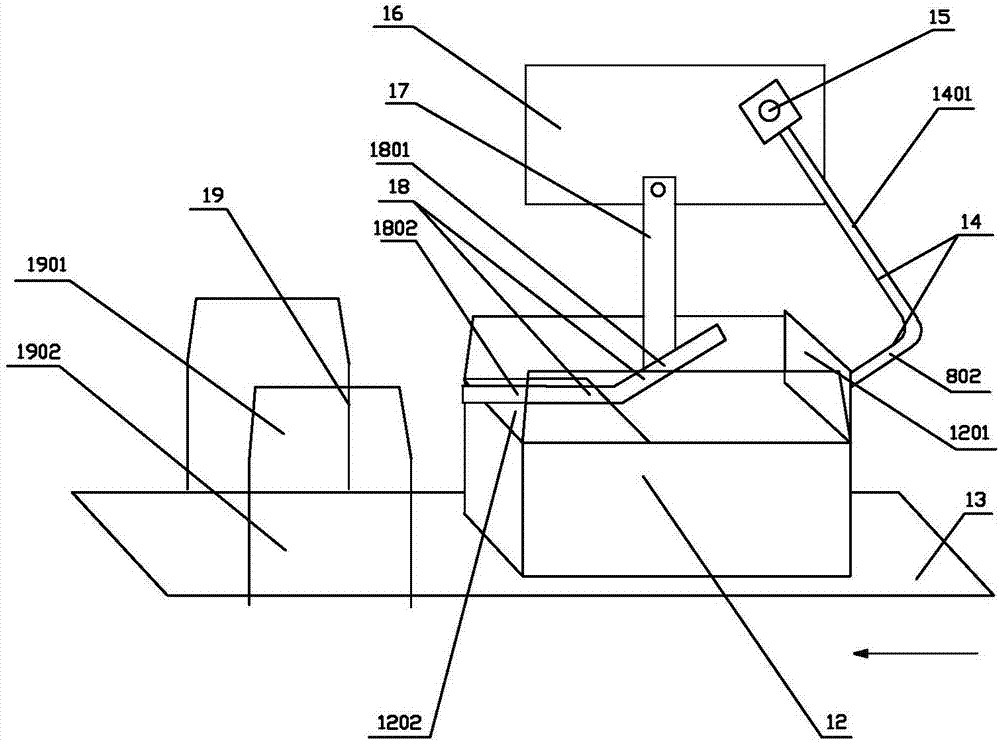

[0034] Embodiment: As shown in the figure, a biomass fuel compression cutting molding and automatic packaging device. After the biomass fuel waste is crushed, mixed with water, stirred and dried, viscous material debris is formed. The compression molding and cutting device includes A compression device for compressing viscous material debris, and a cutting device for cutting the compressed biomass fuel into required sizes.

[0035] Described compressing device comprises square box body 4, and the upper end of box body 4 is provided with feeding port 402, and the upper end of feeding port 402 upper end is fixedly provided with upper and lower feeding hopper 5, and described feeding hopper 5 is conical, and box body 4 There are a plurality of outlets 401 on one side.

[0036] The outside of the box body 4 is provided with a push cylinder 2 for compressing the viscous material debris to increase its internal tightness and push the compressed viscous material debris to the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com