Packaging machine and packaging method for dual-interface card

A dual-interface card, packaging machine technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unstable welding, high product defect rate, slow speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

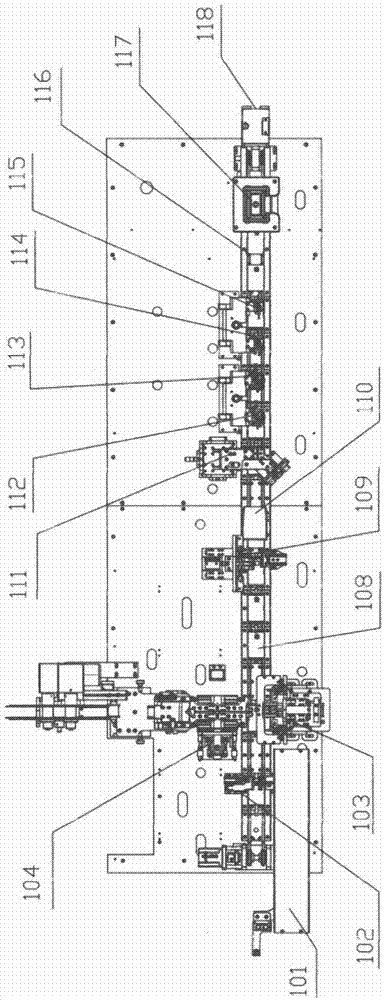

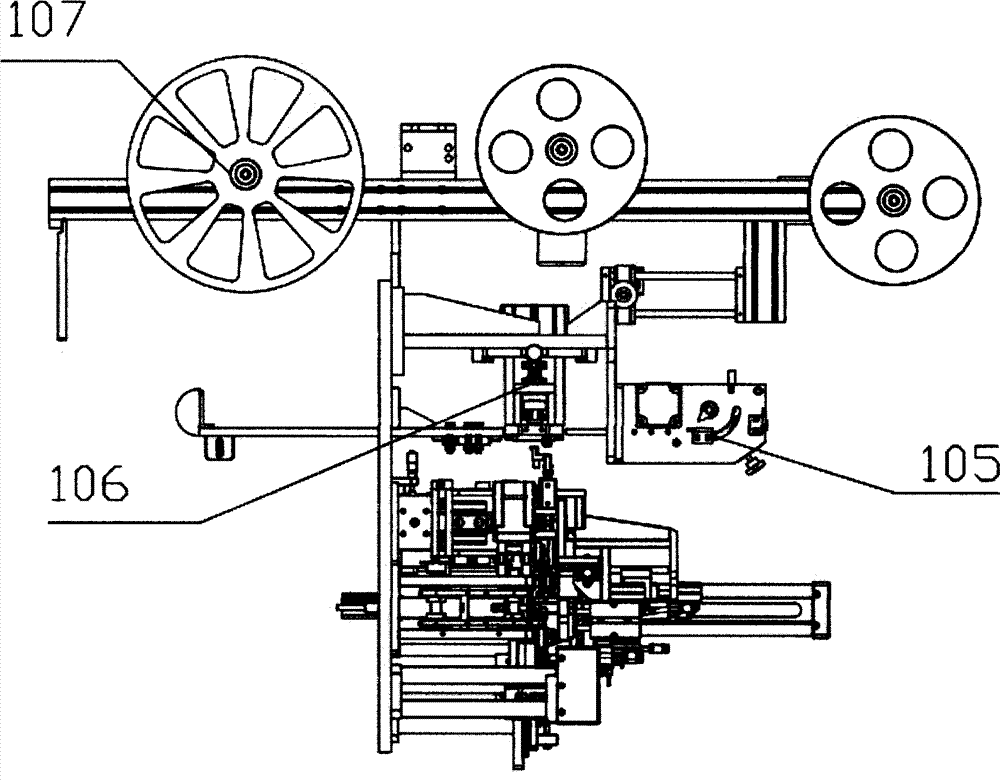

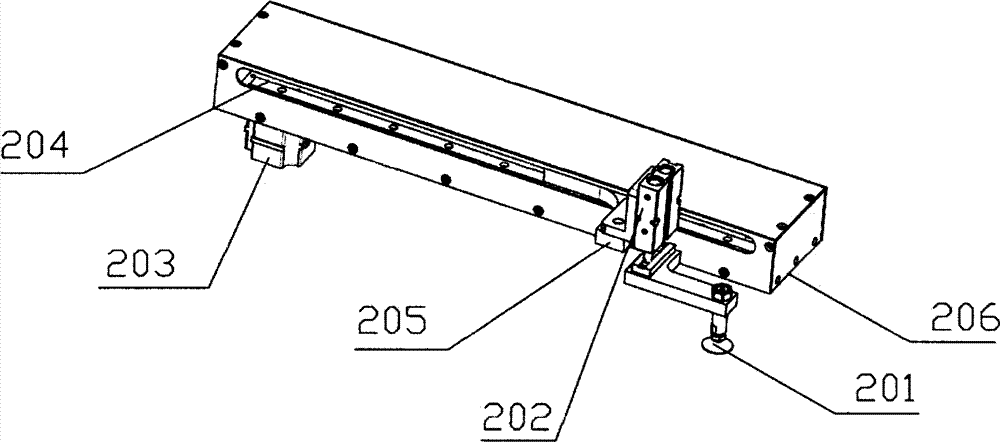

[0030] One embodiment of the present invention is a packaging machine for dual-interface cards, which includes the following devices: card loading arm, Y-direction antenna correction group, chip steering group, antenna correction butt welding group, CCD detection group, chip push-down group , The first non-contact detection group, the correction spot welding group, the first heat welding group, the second heat welding group, the cold welding group, the contact detection group, the second non-contact detection group and the cassette group. like figure 1 , 2 As shown, an embodiment of the present invention includes a card-in transfer arm 101, a Y-direction antenna correction group 102, an antenna correction butt welding group 103, a chip steering group 104, a chip pull strip group 105, a chip punching die 106, and a chip placement Strip group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com