Packing device and packing method thereof

A technology for packaging bags and components, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as low efficiency, reduce production costs, reduce labor intensity, and improve the working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

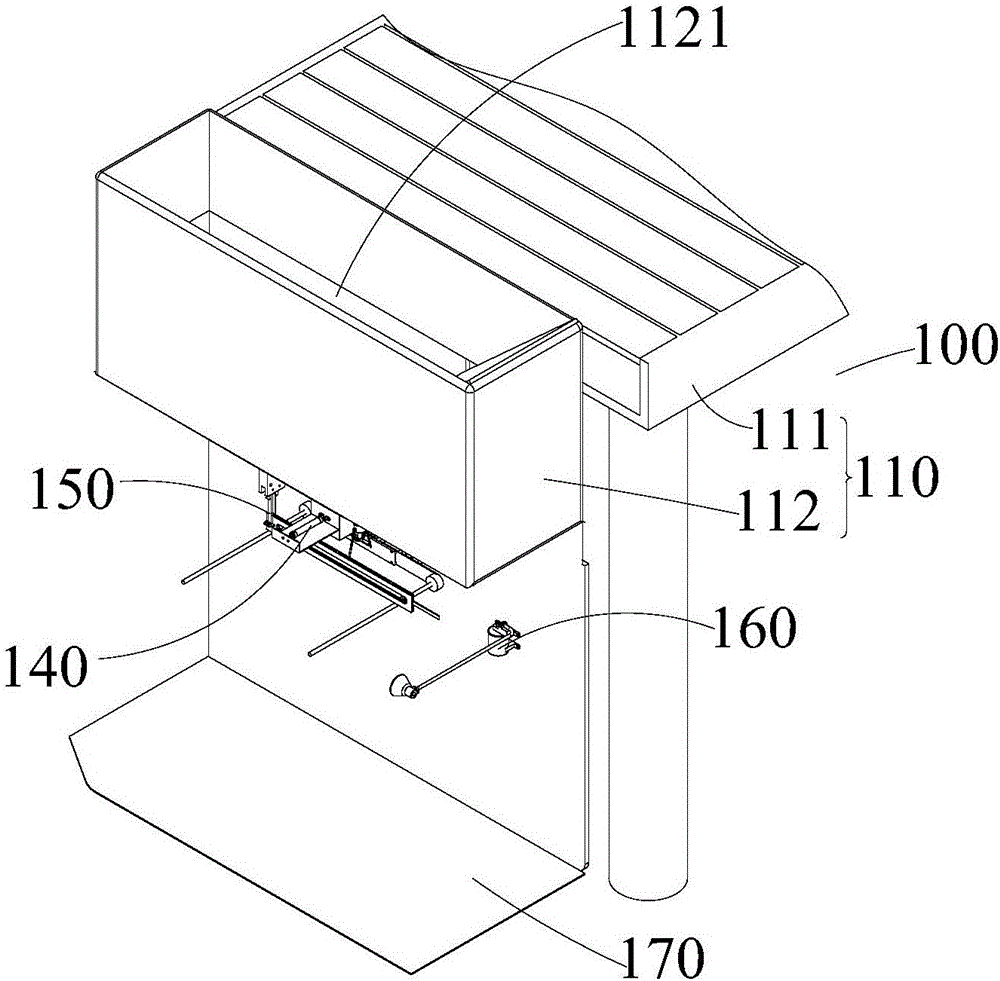

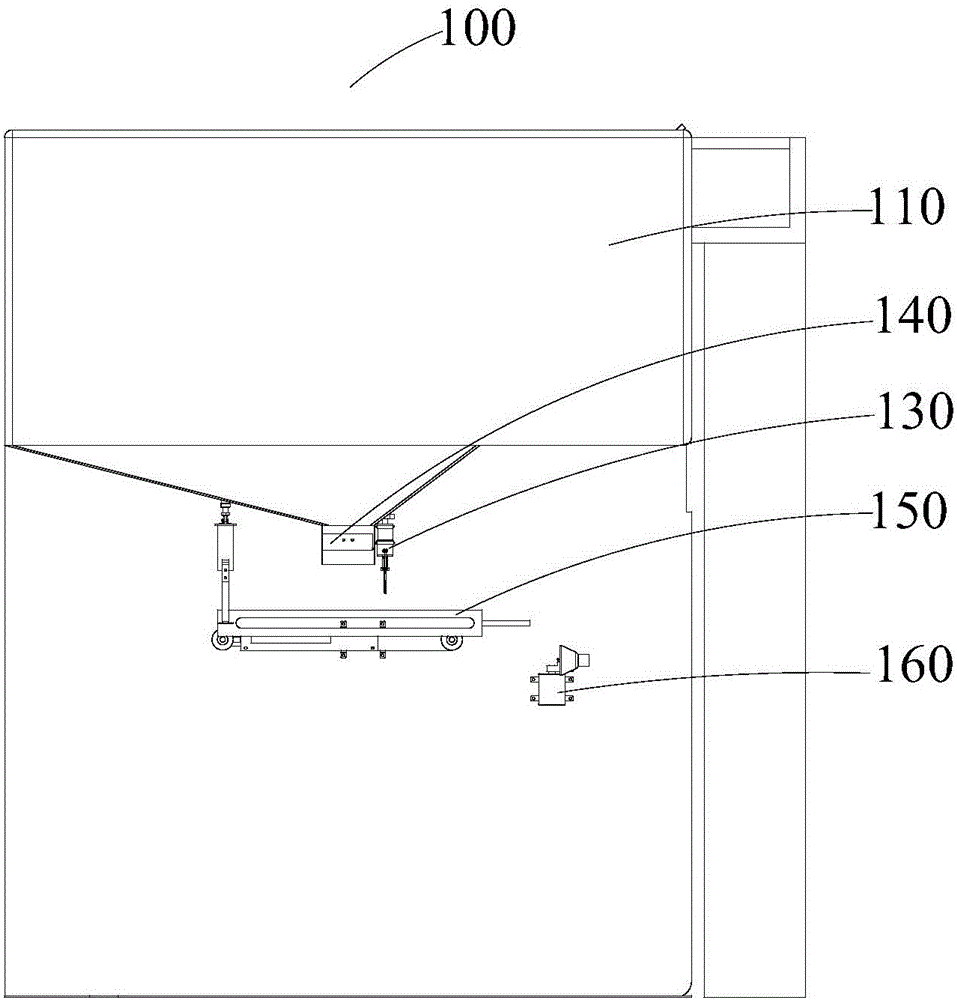

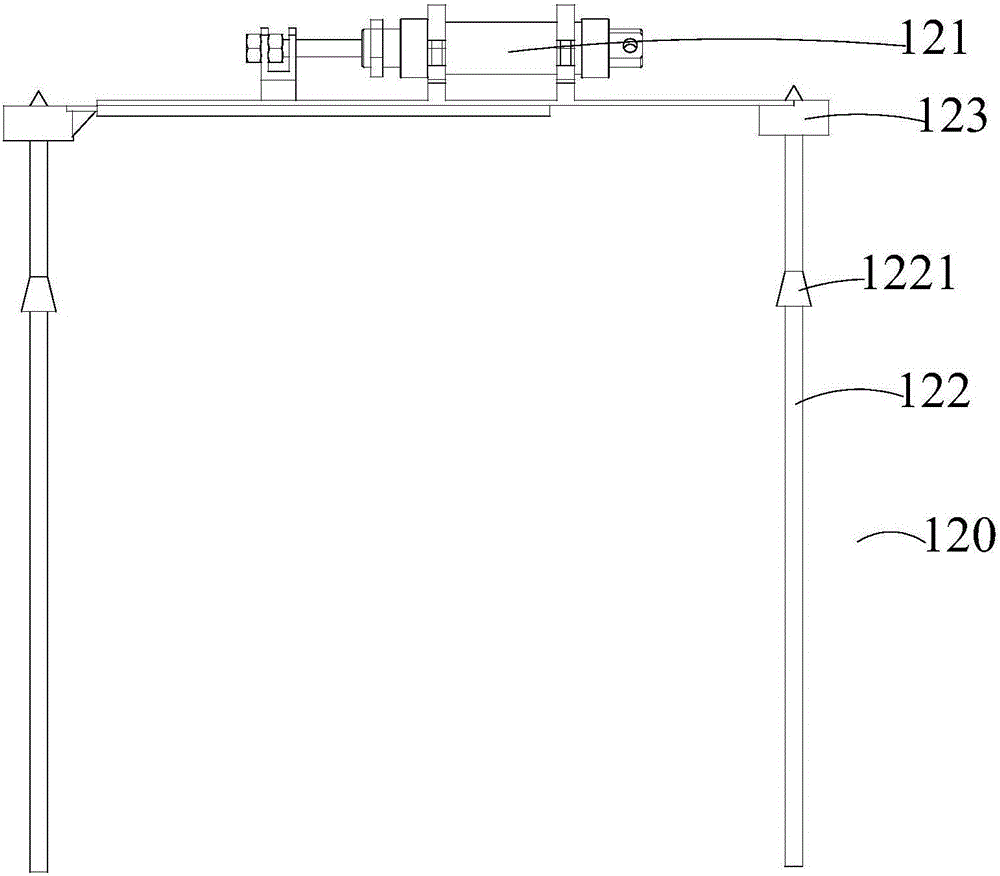

[0124]As an implementable mode, the packaging method also includes a blanking detection step, and the blanking detection step includes the following steps:

[0125] The material throat switch assembly 140 detects whether there is material in the material box 112;

[0126] Simultaneously, the throat switch assembly 140 also detects whether the opening of the packaging bag is opened;

[0127] If so, the switch driving member 141 of the throat switch assembly 140 drives the partition plate 142 to open the discharge port 1121 .

[0128] The switch driving part 141 of the material throat switch assembly 140 is electrically connected with the control assembly to detect whether there is material in the material box 112 and whether the packaging bag is opened. Switch driver 141 detects that there is material and packing bag in the discharge box 112 and opens. At this moment, the discharge port 1121 is opened. At this moment, the material enters in the packing bag to realize the autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com