Automatic tape-wrapping machine

A glue wrapping machine, automatic technology, applied in the direction of cooling/ventilation/heating transformation, to achieve the effect of ensuring quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

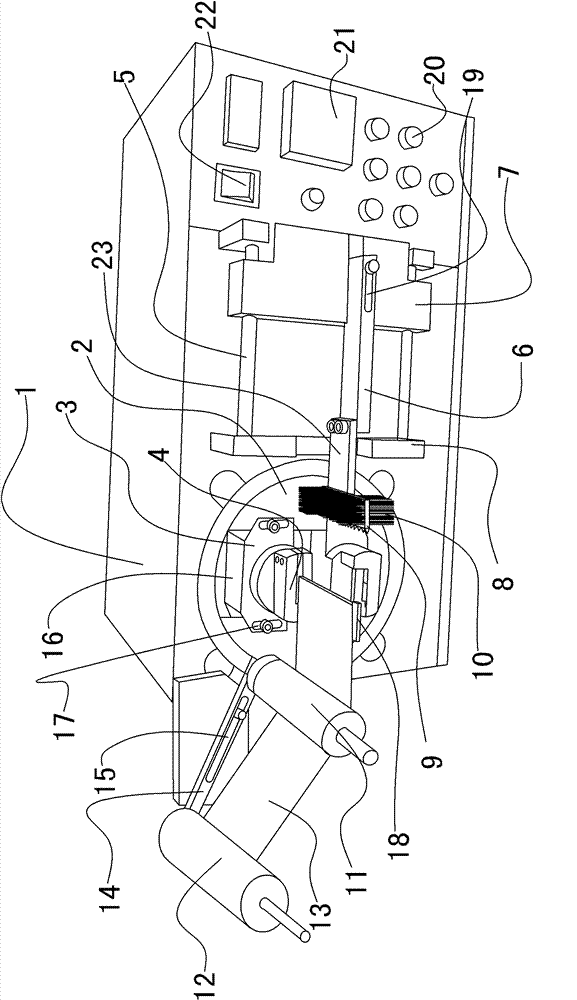

[0020] Please see attached figure 1 , the main body of the present invention is a frame 1. In this embodiment, the left end of the frame 1 is fixedly equipped with a tape support 14. In this embodiment, the tape support 14 has a first waist-shaped hole 15, and the tape support 14 is in the The first waist-shaped hole 15 is fixed on the frame 1 by screws, so that the protruding length of the tape support 14 can be easily adjusted to be suitable for different tapes. A tape reel 12 is arranged on the top of the tape support 14, and a tape 13 is wound on the tape reel 12. A main shaft 2 is installed on the frame 1. In the present embodiment, a main shaft driving device (not shown in the figure) is provided in the frame 1. The main shaft driving devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com