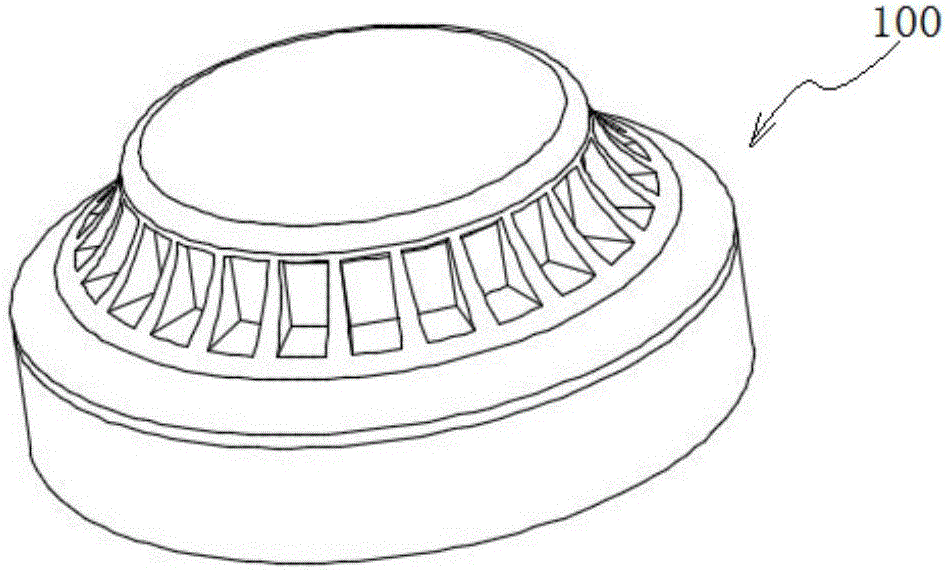

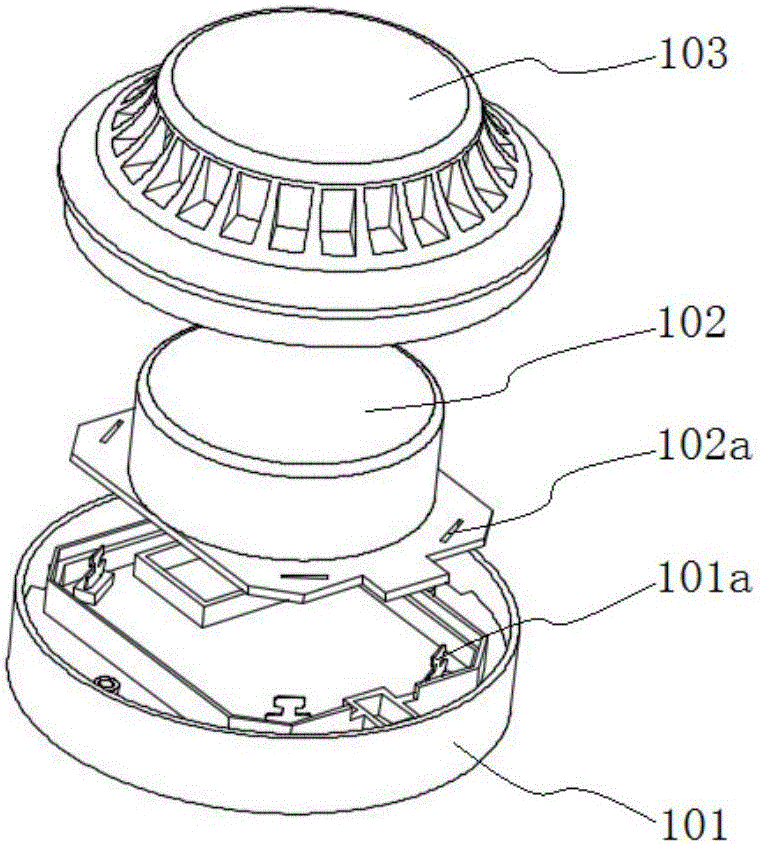

Packing and stacking device for smoke alarm assembly production line

A smoke alarm and stacking device technology, applied in packaging, packaging machines, object stacking, etc., can solve the problems of low efficiency and high cost, and achieve the effect of simple structure of the blocking mechanism, good quality, accurate and stable push

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

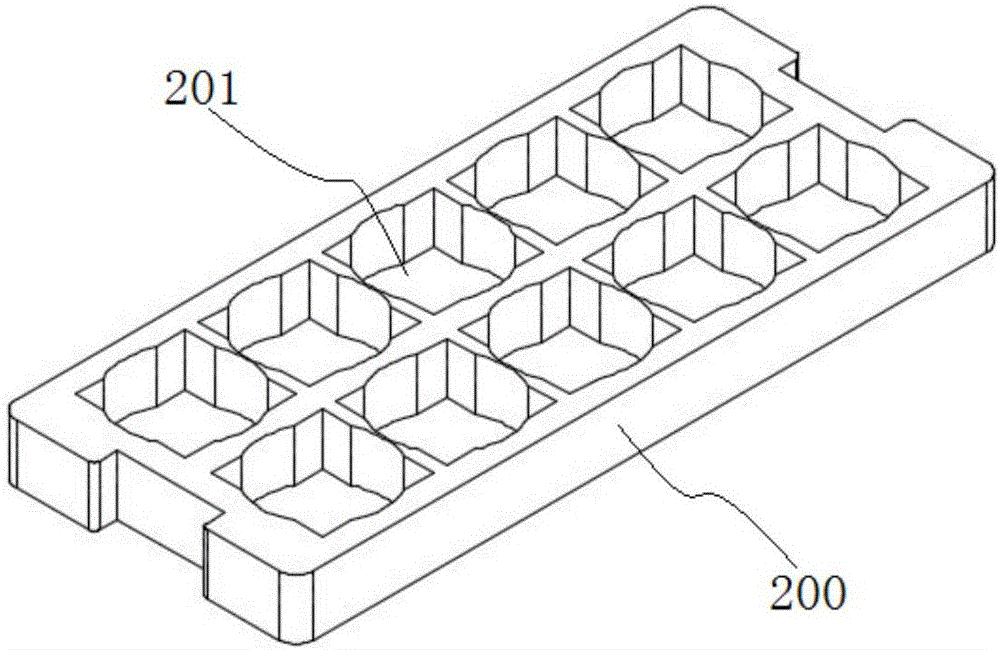

[0043] Combine Figure 4 with Figure 5 As shown, a packaging and palletizing device for a smoke alarm assembly production line of this embodiment includes a packaging box feeding device 2, a grabbing and packaging device 3, a conveying device 4, and a palletizing device 5. The conveying device 4 is provided in the packaging box feeding device Between 2 and the palletizing device 5, it is used to transport the packaged products to the palletizing device 5. Image 6 As shown, the packaging box feeding device 2 includes a packaging pushing mechanism 21 and a blocking mechanism 23. The packaging pushing mechanism 21 and the blocking mechanism 23 are provided at one end of the conveying device 4, and the packaging pushing mechanism 21 is used to push the packaging box 200 onto the conveying device 4. , The blocking mechanism 23 is used to block the packaging box 200 being pushed onto the conveying device 4, and release the blocking of the packaging box 200 after the product packaging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com