Seedling soil ball baling press with straw ropes

A technology of straw rope and seedlings, which is applied in the field of packaging machines and seedling soil ball grass rope balers, can solve problems such as retention, decline in seedling survival rate, and loss, and achieve considerable efficiency, reduce labor burden, and protect the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

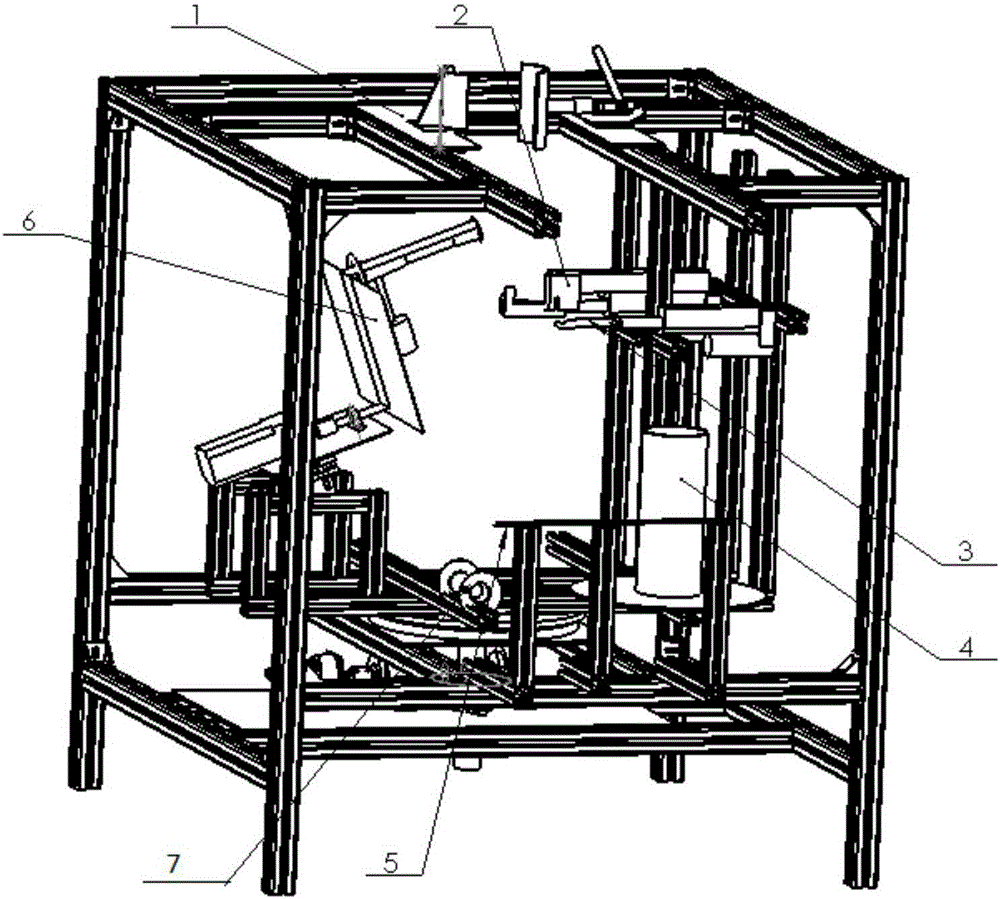

[0021] Such as figure 1 As shown, the seedling soil ball grass rope baler consists of a clamping mechanism 1, a shearing mechanism 2, a hook knife mechanism 3, a rotating grass rope mechanism, a seedling tray 5, a grass rope winding mechanism 6, a grass rope limit tube 7 and a peripheral bracket composition. Seedling stock tray 5 and grass rope limit pipe 7 are all fixed on the peripheral support by bolts. The rotating grass rope mechanism is made up of hollow shaft, bearing and straw rope loading pallet 4;

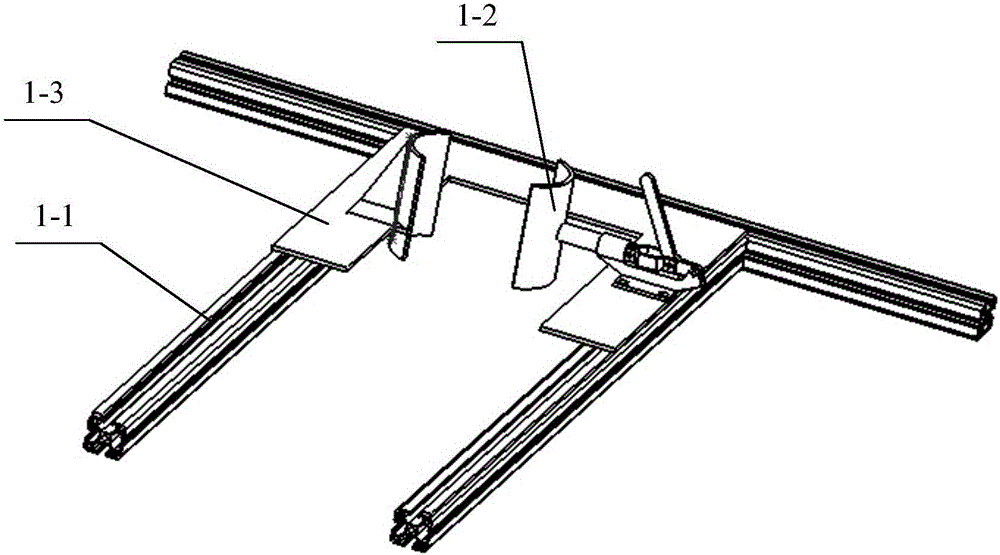

[0022] Such as figure 2 As shown, the clamping mechanism 1 is made up of slide rail 1-1, fixture, circular splint 1-2 and supporting plate 1-3; Fixture comprises movable part and fixed part; The base of fixed part and movable part is all bolted on On the supporting plate 1-3, the supporting plate and the slide rail 1-1 form a sliding pair, and the slide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com