Quick detachable joint of nuclear fuel assembly

A nuclear fuel assembly and fast technology, applied in the assembly of fuel elements, nuclear power generation, climate sustainability, etc., can solve the problem of unreliable disassembly and reassembly operations, fuel assemblies that cannot be used again, and sleeve screws that cannot be screwed in place, etc. problem, to achieve the effect of convenient removal and reinstallation of the upper pipe seat, saving man-hours, and accurate and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

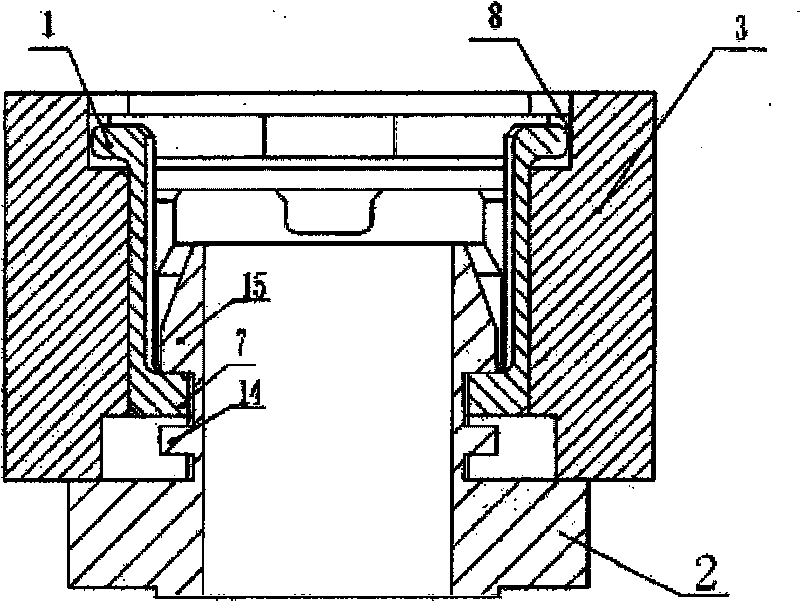

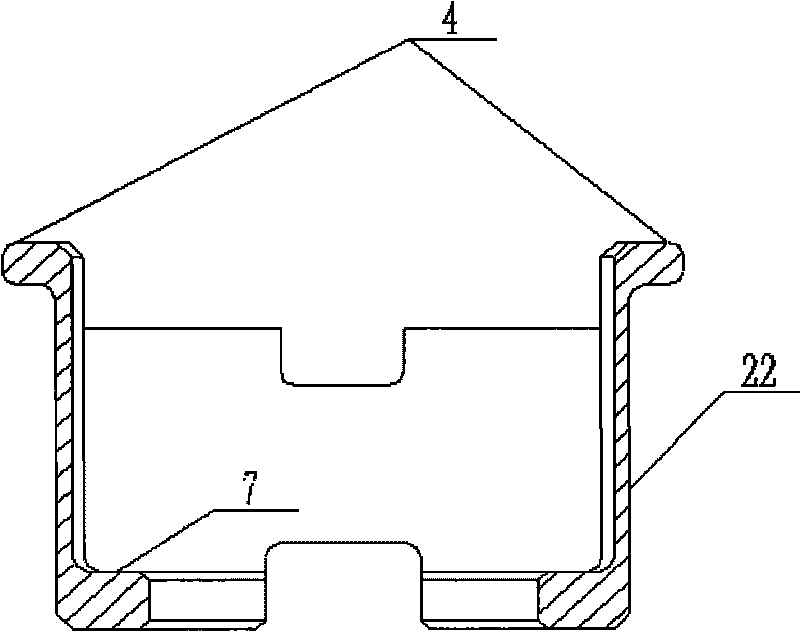

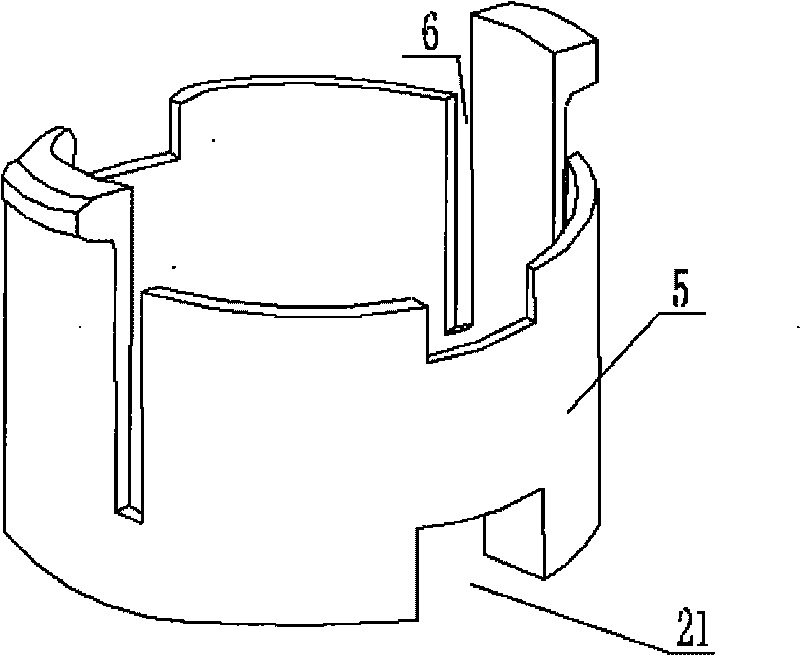

[0024] Such as figure 1 , figure 2 and image 3 As shown, a quick detachable joint of a nuclear fuel assembly is composed of a locking ring 1 , an upper stem 3 and a joint 2 . The locking ring 1 is a columnar hollow structure, and its lower end has an inwardly convex circular ring structure step 7 integrated with the lower end. There are two symmetrically distributed through grooves 21 at the step 7, and the upper end is connected vertically to the lower end. There are two symmetrically distributed tool grooves 6 in the direction of the groove line. The upper end of the locking ring 1 also has two symmetrically distributed straight arm positioning locking hooks 4 protruding radially along the locking ring 1. The locking ring 1. The position for fixing and positioning the locking claw 4 is a strip structure 22 whose radian is consistent with that of the side wall of the locking ring. An axial gap is provided between the upper part of the strip structure 22 and the side wall ...

Embodiment 2

[0027] Such as Figure 4 , Figure 5 As shown, a quick detachable joint of a nuclear fuel assembly is composed of a locking ring 1, an upper pipe seat 3 and a joint 2, wherein the upper pipe seat 3 and the joint 2 have the same structure as that described in Embodiment 1, and the locking ring 1 of this embodiment The upper end of the ring 1 has an arc structure. One end of the arc structure is a fixed end 16 fixed to the upper end of the locking ring or integrated with the upper end of the locking ring, and the other end is a free end 17. The arc structure and the side wall There is a gap along the circumferential opening of the locking ring. The curvature of the arc-shaped structure gradually decreases from the fixed end to the free end. It has an integrated structure with the free end 17, and the arc-shaped positioning and locking claw 18 is an arc-shaped structure. The locking ring installation groove 8 and the claw positioning pit 12 are matched with the convex part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com