Single fiber bi-directional optical element and assembly method thereof

A single-fiber bidirectional, optical component technology, applied in the field of optical network devices, can solve the problems of low production efficiency, high cost, and inability to produce in large quantities, and achieve the effect of improving packaging efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

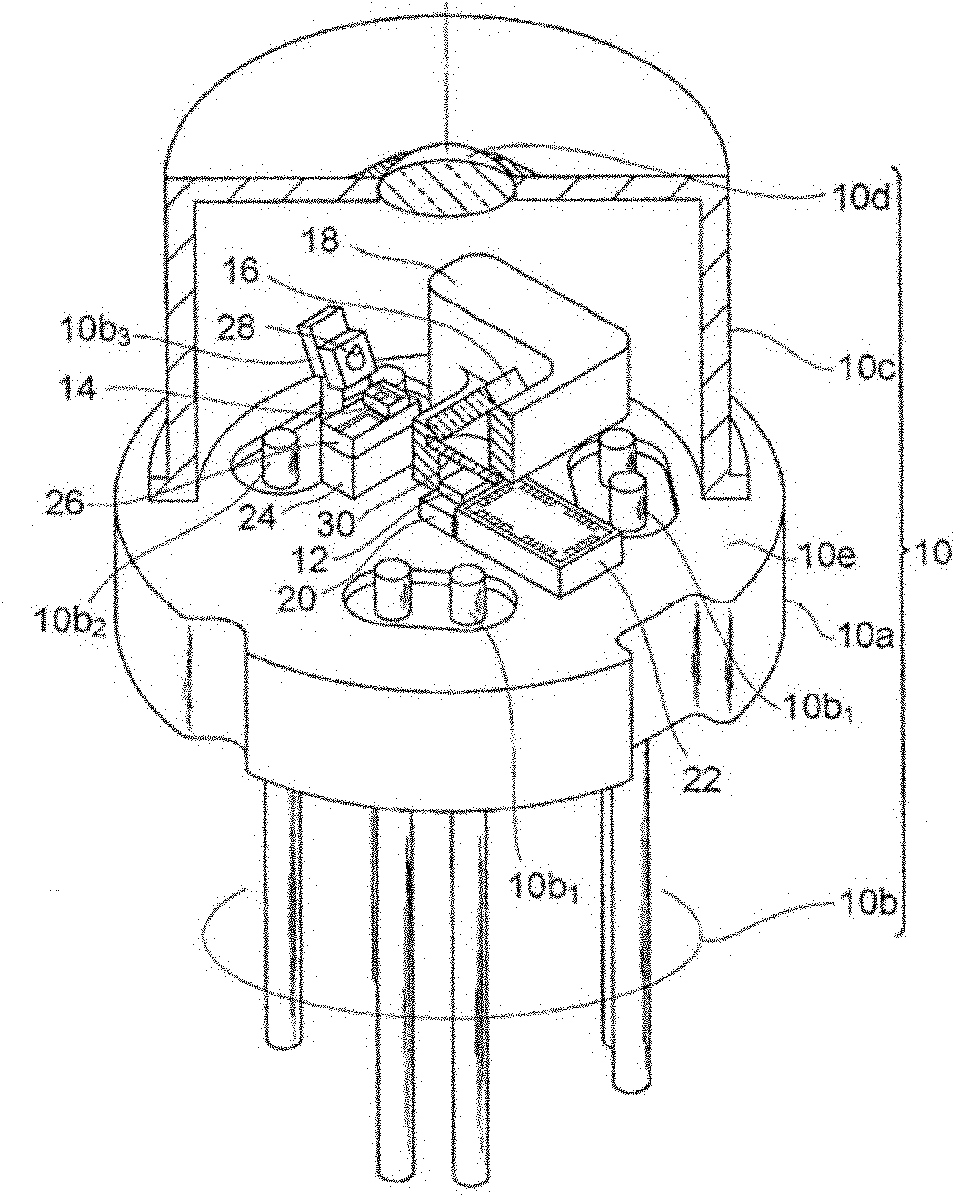

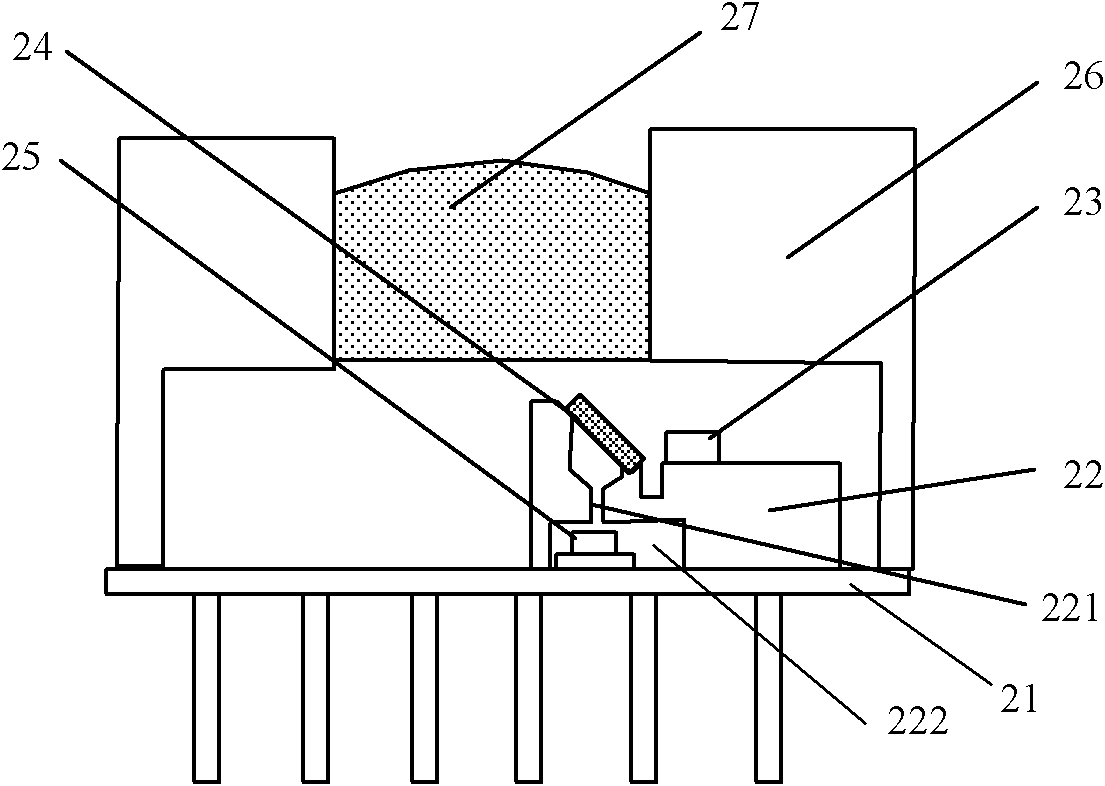

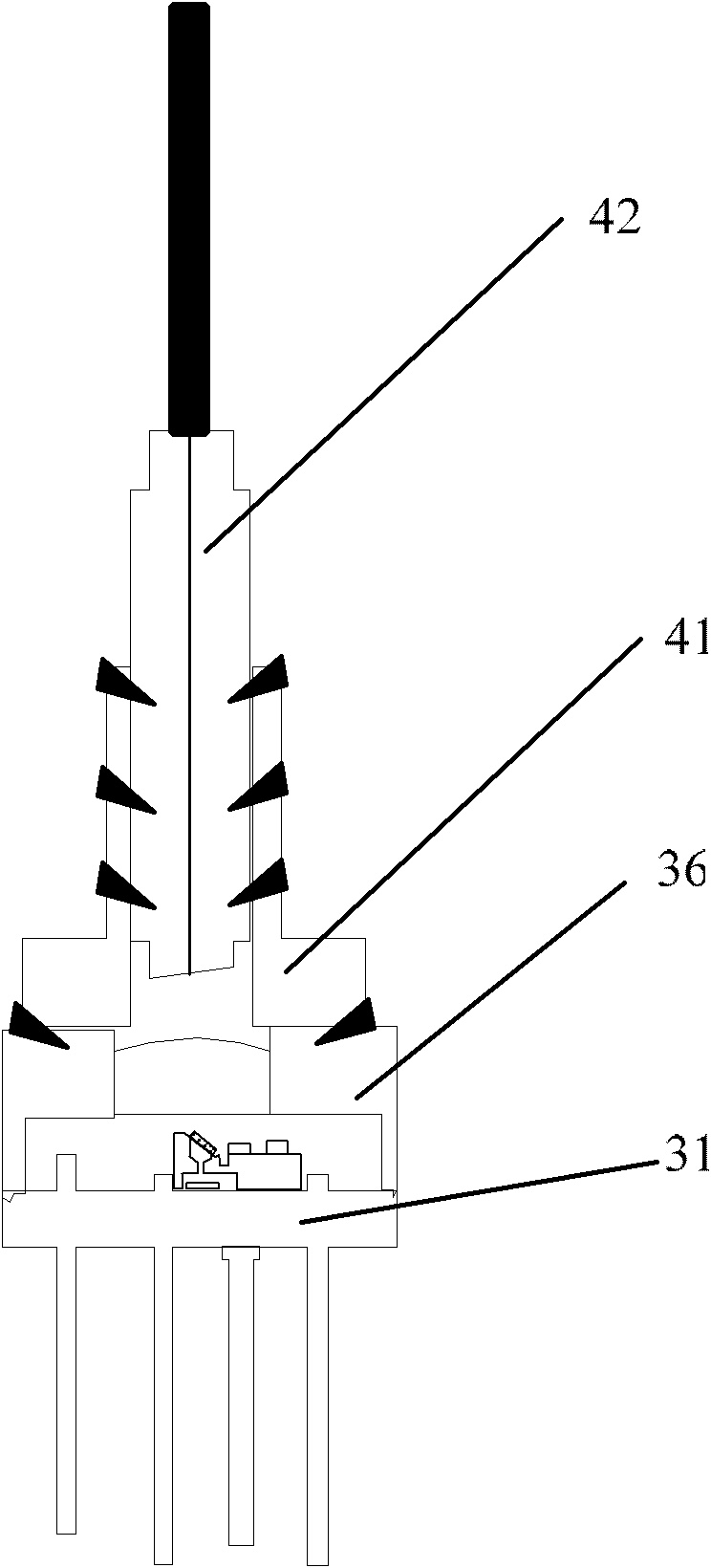

[0030] image 3 It is an axial sectional view of an embodiment of the single-fiber bidirectional optical component provided by the present invention, Figure 4 Yes image 3 Axial cross-sectional view of other structures except optical fiber and its fixing parts in . The single-fiber bidirectional optical component in this embodiment is a pigtail type single-fiber bidirectional optical component, and the alignment optical interface is an optical fiber.

[0031] like image 3 and Figure 4 As shown, the single-fiber bidirectional optical component in this embodiment includes a stem 31 on which a base 32 is fixed, and a filter 34 and a laser 33 are fixed on the base 32 . In this embodiment, the laser 33 may be a laser diode (LD). The light output from the laser 33 enters the pigtail 42 after being reflected by the filter 34 . The fixing method between the laser 33 and the base 32 can be adhesive bonding, eutectic welding or laser brazing, and the fixing method between the f...

Embodiment 2

[0045] Figure 5 It is an axial sectional view of another embodiment of the single-fiber bidirectional optical component provided by the present invention, such as Figure 5 As shown, the single-fiber bidirectional optical component in this embodiment is a pluggable single-fiber bidirectional optical component.

[0046] The single-fiber bidirectional optical component in this embodiment includes a stem 51 on which a base 52 is fixed, and a filter 54 and a laser 53 are fixed on the base 52 . The laser 53 can be a laser diode. The light output from the laser 53 enters the pigtail 52 after being reflected by the filter 54 . The fixing method between the laser 53 and the base 52 can be adhesive bonding, eutectic welding or laser brazing. The fixing methods between the base 52 and the stem 51 include but not limited to adhesive bonding, eutectic bonding, laser brazing or laser welding. A photoelectric conversion device 55 fixed on the stem 51 is arranged below the base 52 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com