Automatic tube feeding multi-cutter tube cutting device of bearing steel tube

A technology for bearing steel pipes and feeding pipes, which is applied in the direction of pipe shearing devices, shearing devices, and accessories of shearing machines, etc. It can solve the problems of increased processing costs, inability to guarantee the accuracy of parts, and low production efficiency, so as to improve work efficiency, Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

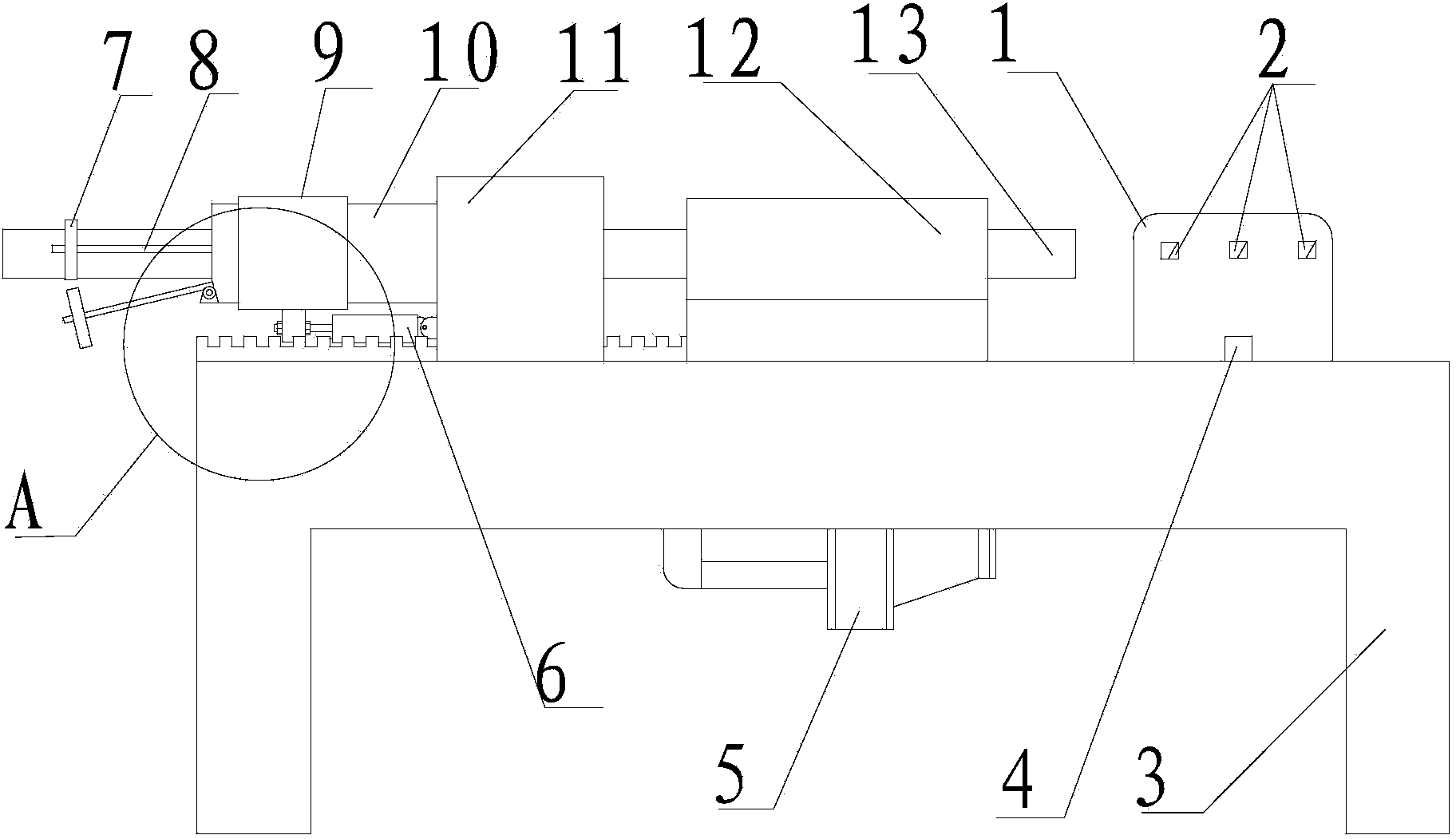

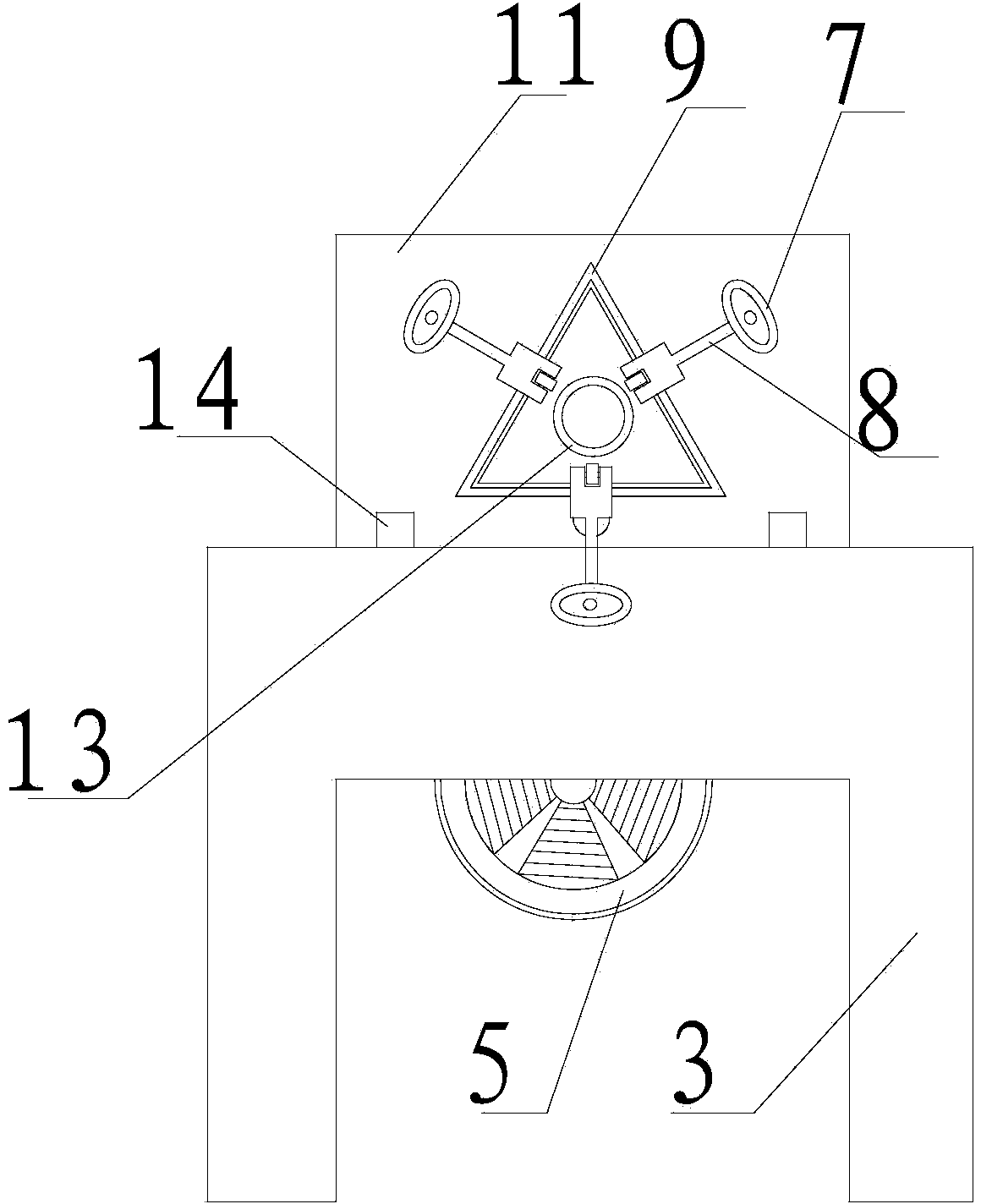

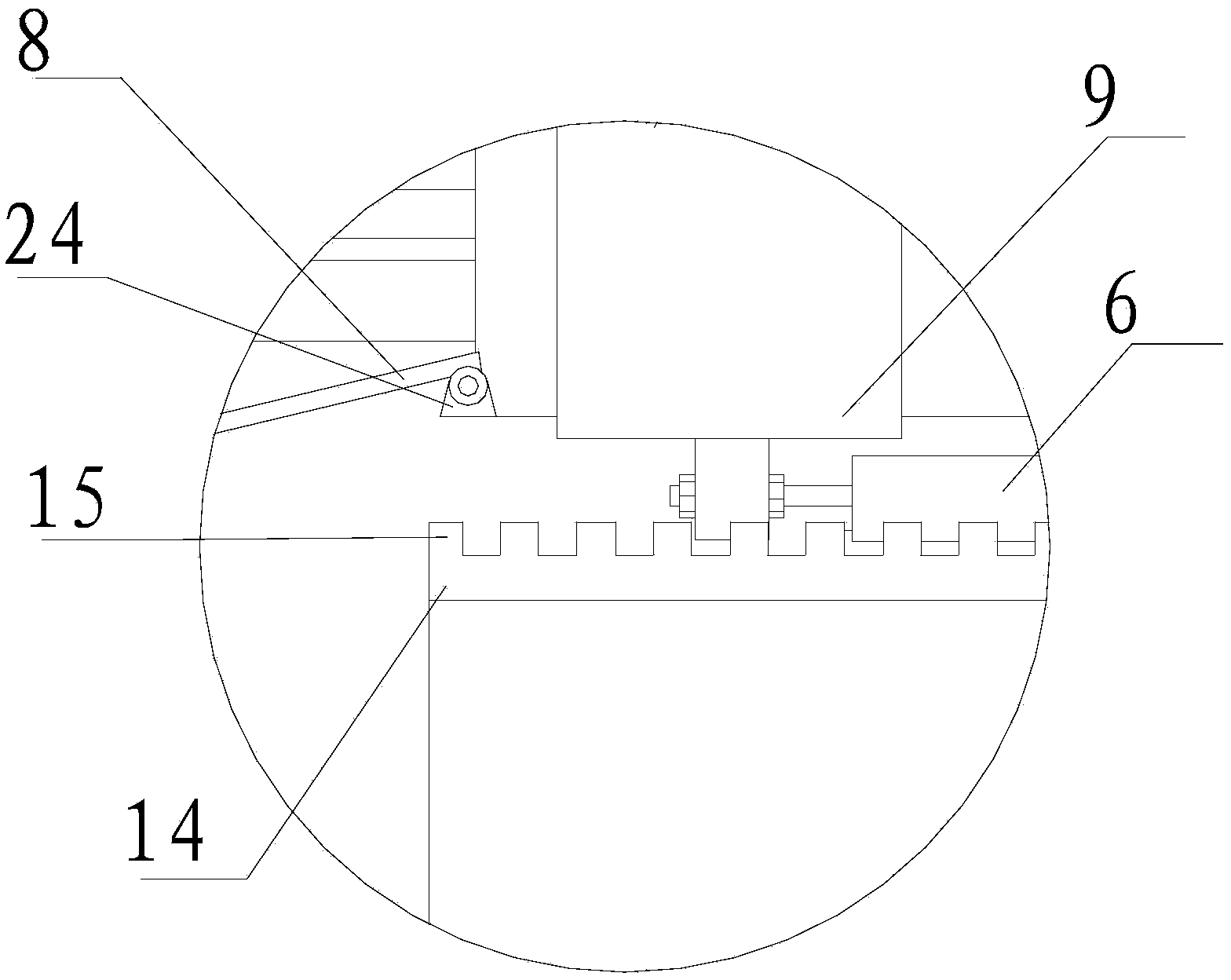

[0020] Refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , The present invention is an automatic pipe feeding and multi-knife pipe cutting device for bearing steel pipes, which includes a worktable 3, a tool post 1, a tool post track 4 and a toothed track 14. The toothed track 14 is installed on the worktable 3 and the toothed track 14 A pipe-feeding seat 11 is installed, the pipe-feeding seat 11 is installed in cooperation with the triangle seat 10, the triangle seat 10 is installed in cooperation with the clamping sleeve 9, and the triangle seat 10 is installed with a clamping shaft 8, the clamping shaft 8 A clamping wheel 7 is installed at the end of the tool, a rotating tube seat 12 is installed on the worktable 3, the tool holder rail 4 is installed on the worktable 3, and a tool holder 1 is installed on the tool holder rail 4. Several pipe cutters 2 are installed on 1. There are 3 pipe cutting knives 2, 3 pipe cutting knives 2 are sequentially installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com