Cable intermediate connector and manufacturing and mounting method therefor

A cable intermediate joint and intermediate joint technology, which is applied in cable joints, equipment for connecting/terminating cables, etc., can solve the problems of poor connection of conductor connecting pipes, imperfect joint sealing and waterproofing, insufficient mechanical strength, etc., to improve adaptability. performance, enhance mechanical protection performance and sealing performance, and ensure the effect of effective contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

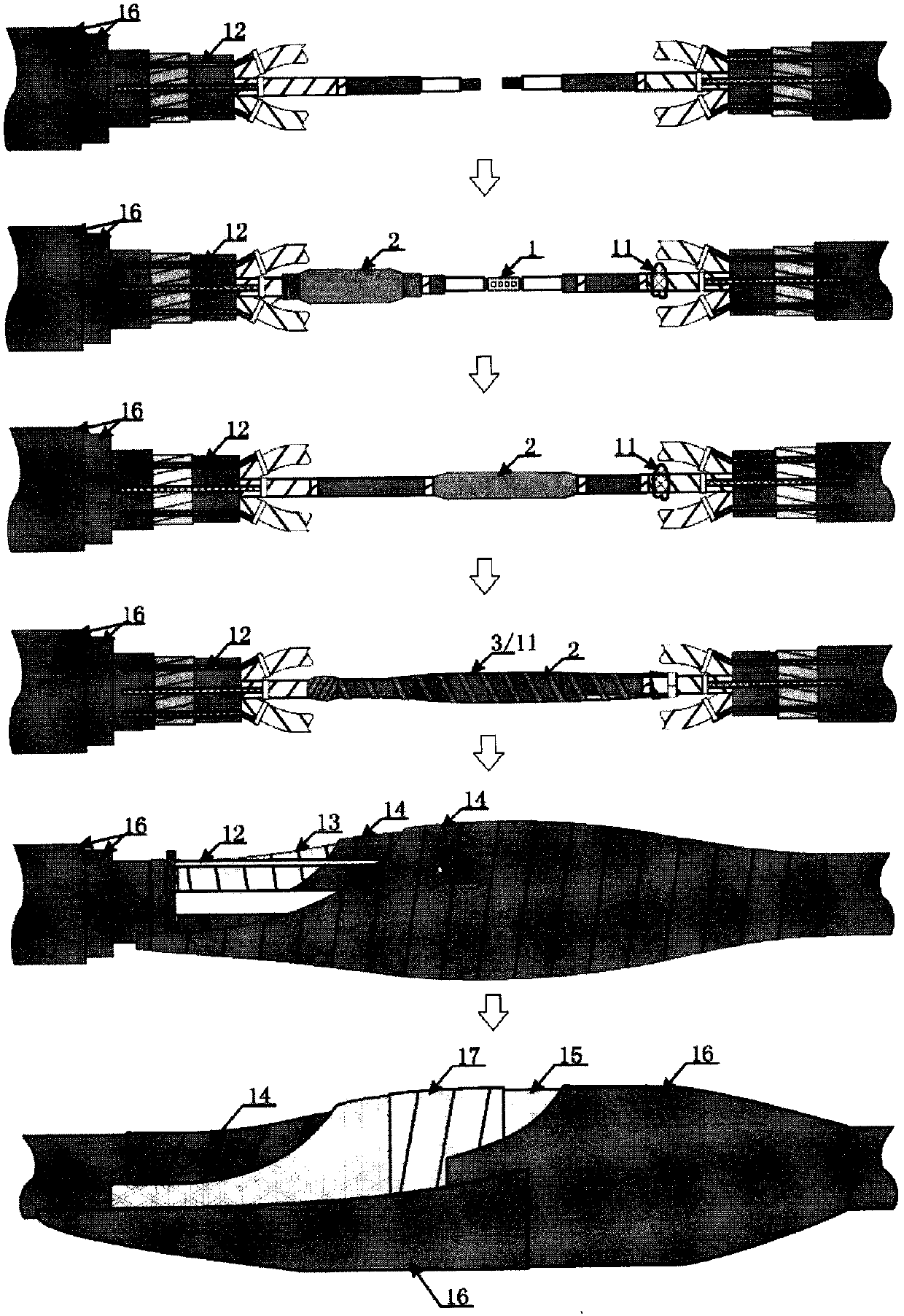

[0041] The technical solution of the present invention will be further introduced in detail below in conjunction with the accompanying drawings and specific embodiments.

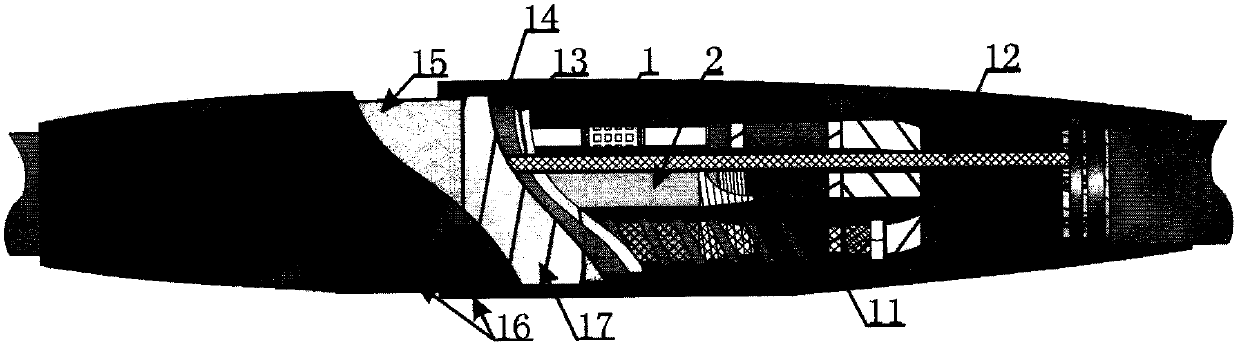

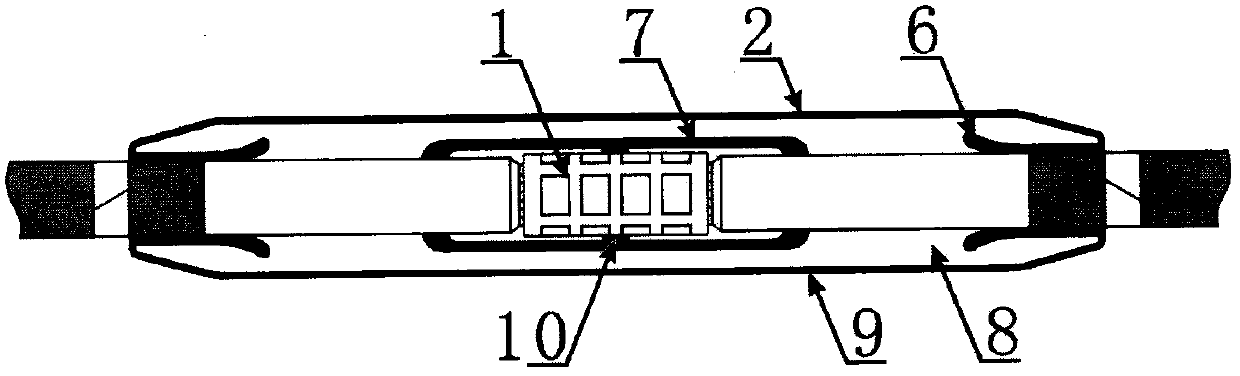

[0042] Such as figure 1 As shown, the present invention provides a cable intermediate joint for connecting three-phase cables of two-circuit power cables. Part 3. Cable inner sheath recovery part 4. Mechanical protection and waterproof sealing part 5, characterized in that:

[0043] The intermediate joint adopts a multi-layer solid composite dielectric insulation and sealing structure.

[0044] The main body 2 of the cold-shrinkable intermediate joint adopts an integrated multi-layer composite structure, including a stress cone 6, an inner shielding layer 7, an insulating layer 8 and an outer shielding layer 9 from the inside to the outside; the main body of the cold-shrinkable intermediate joint each The layers are all made of liquid silicone rubber material, of which the stress cone, the inner and outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com