Deep-water packer

A packer and deep-water technology, applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., can solve problems such as destruction, cumbersome operation, and formation environmental pollution, so as to avoid cumbersome operation and simple and convenient operation , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

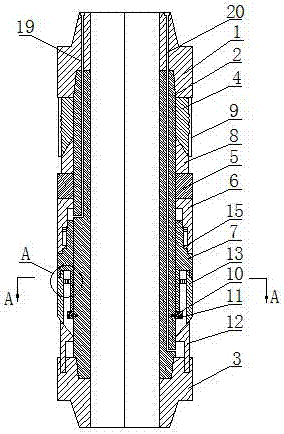

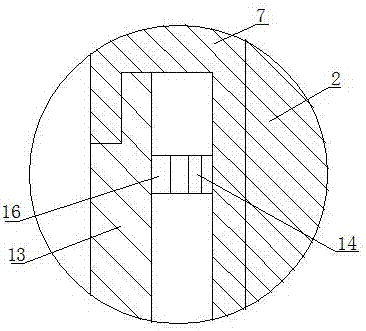

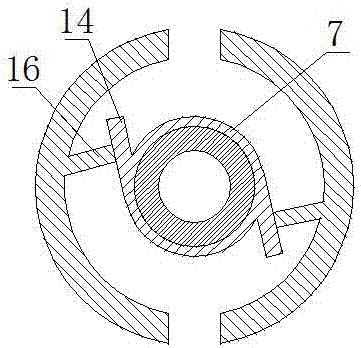

[0022] The deepwater packer includes an upper joint 1, a central pipe 2, a lower joint 3, slips 4, a rubber sleeve 5, a sliding sleeve 6 and a locking sleeve 7. The upper joint 2 is threaded on the top end of the central pipe 1; the bottom end of the central pipe 1 The lower joint 3 is threaded, and the central pipe 1 below the upper joint 1 is equipped with slips 4 through the upper vertebral body 8, and the upper vertebral body 8 is connected to the slips 4 by sliding contact; the slips 4 are provided with a slip cover 9, The slip cover 9 is threadedly connected with the upper joint 1, and the slips 4 can protrude from the slip cover 9 under the thrust of the upper vertebral body 8, and the slips 4 can be retracted to the slips after the thrust of the upper vertebral body 8 is eliminated. Inside the cover 9.

[0023] The central tube 2 below the upper vertebral body 8 is fitted with a sliding sleeve 6 and a locking sleeve 7, and a stopper 11 is installed on the central tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com