Isometric process control method utilizing PVT (pressure-volume-temperature) relation of polymers

A technology of relational characteristics and process control, which is applied in the field of specific volume process control, can solve the problem of establishing a connection with the PVT database without polymers, and achieve the effects of uniform cooling shrinkage, reduced specific volume, and reduced orientation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

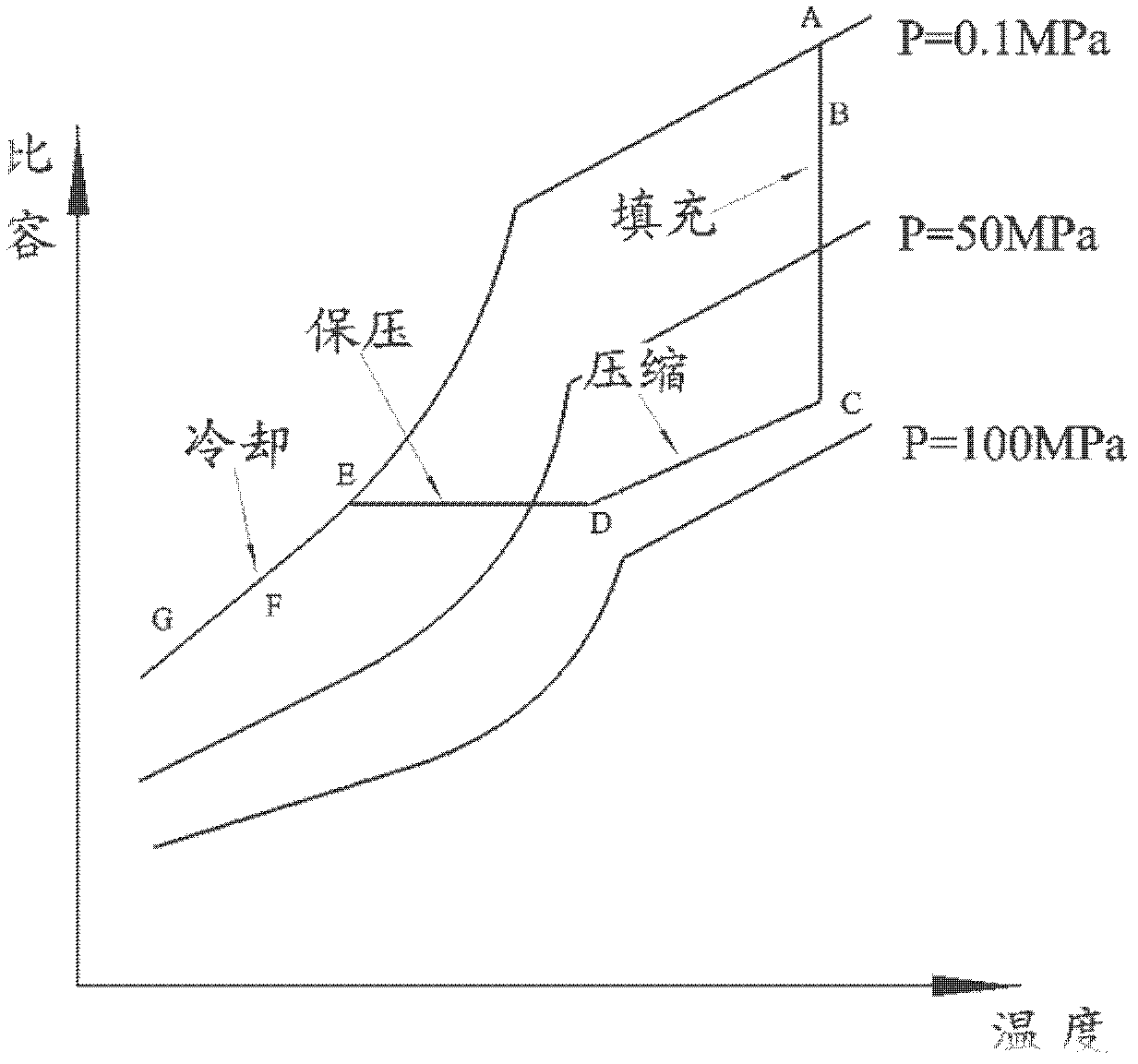

[0015] The specific implementation method of an isosteric process control method using the PVT relationship characteristics of polymers in the present invention is as follows: first, according to the physical parameters of different materials, the PVT curve of the injection molding material is obtained, and the molding process route is determined. Get the process route of A-B-C-D-E-F in the PVT curve, such as figure 1 As shown, point A is the starting point of the injection molding process. From point A, the molten material is injected into the cavity from the nozzle. Point B is the moment when the sensor installed in the cavity monitors the pressure and temperature signals, that is, the material just touched the molten material. When it is in the body, the temperature will suddenly rise to the maximum value, and the pressure will also rise to a certain extent, but the change value is not large. The pressure rising slope is related to the injection pressure and injection speed....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com