Mold shell cooling device after wax mold dewaxing

A cooling device and dewaxing technology, which is applied in the direction of casting molding equipment, molds, cores, etc., can solve the problems of wax mold deformation, affecting operation, wax mold slag drop, etc., achieve uniform cooling shrinkage, ensure dimensional accuracy, and cool consistent speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings in the embodiments of the present invention. In the description, it should be understood ", "Right" and other indicated orientations or positional relationships are only corresponding to the drawings of the present invention. In order to facilitate the description of the present invention, they do not indicate or imply that the referred device or element must have a specific orientation:

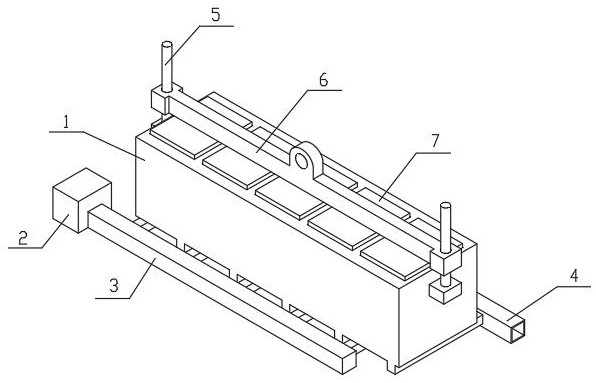

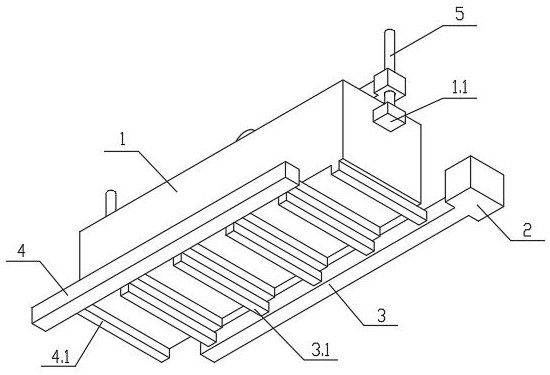

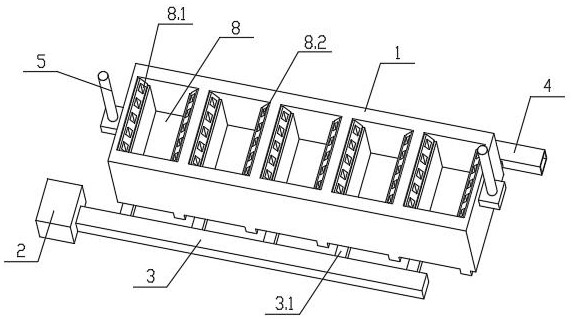

[0023] see Figure 1-7 , the present invention provides a technical solution: a mold shell cooling device after wax mold dewaxing, including a box body 1, the box body 1 is provided with a plurality of cooling chambers 8 for cooling the mold shell at intervals, and the upper part of the box body 1 is provided with There is a crossbeam 6, and the lower part of the crossbeam 6 is provided with a plurality of sealing covers 7 corresponding to the openings of the cooling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com