Hot pressing die with low thermal conductivity coefficient layer on surface

A low thermal conductivity, hot-pressing mold technology, applied in the field of mold temperature adjustment, can solve problems such as unevenness and unsightly appearance, and achieve the effects of high speed, increased work efficiency, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

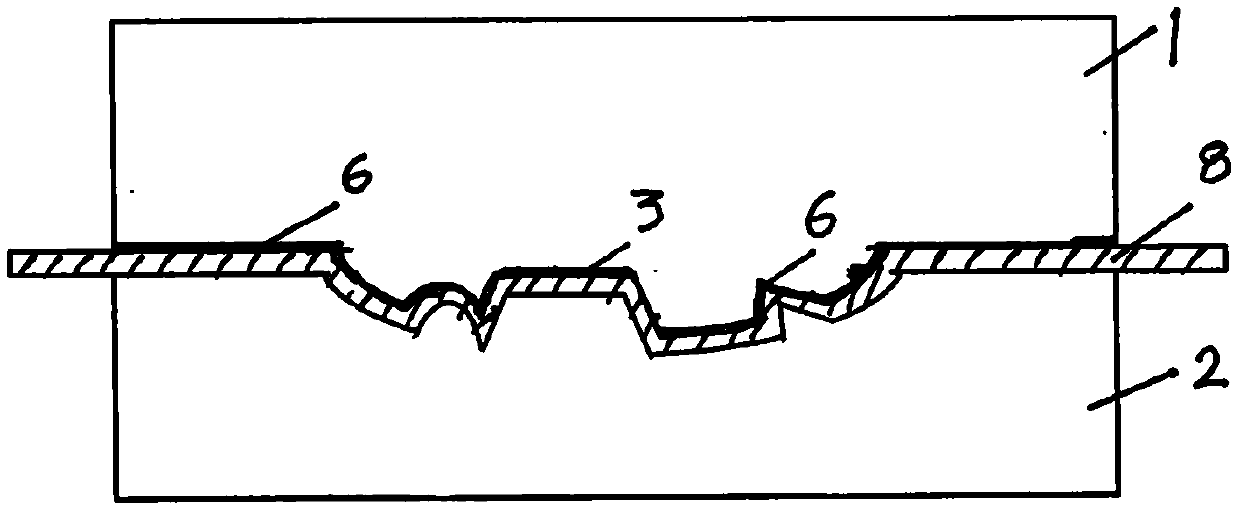

[0052] Embodiment 1, the hot pressing mold that the whole surface of mold steel upper mold has low thermal conductivity layer

[0053] Such as figure 1 , a hot-pressing mold with a low thermal conductivity layer on the surface, including a matching die steel upper die 1 and a die steel lower die 2, the die steel upper die 1 is located above the die steel lower die 2, and all of the die steel upper die 1 The contact surface is provided with a low thermal conductivity surface layer 3 with a thermal conductivity lower than that of the mold steel body, that is, a low-temperature surface layer lower than the temperature of the mold steel body is provided on all contact surfaces of the mold steel upper mold 1 . The low thermal conductivity surface layer 3 is a low thermal conductivity material coating 6 nitrile rubber coating, and the thermal conductivity is 0.250 / W / m°C.

Embodiment 2

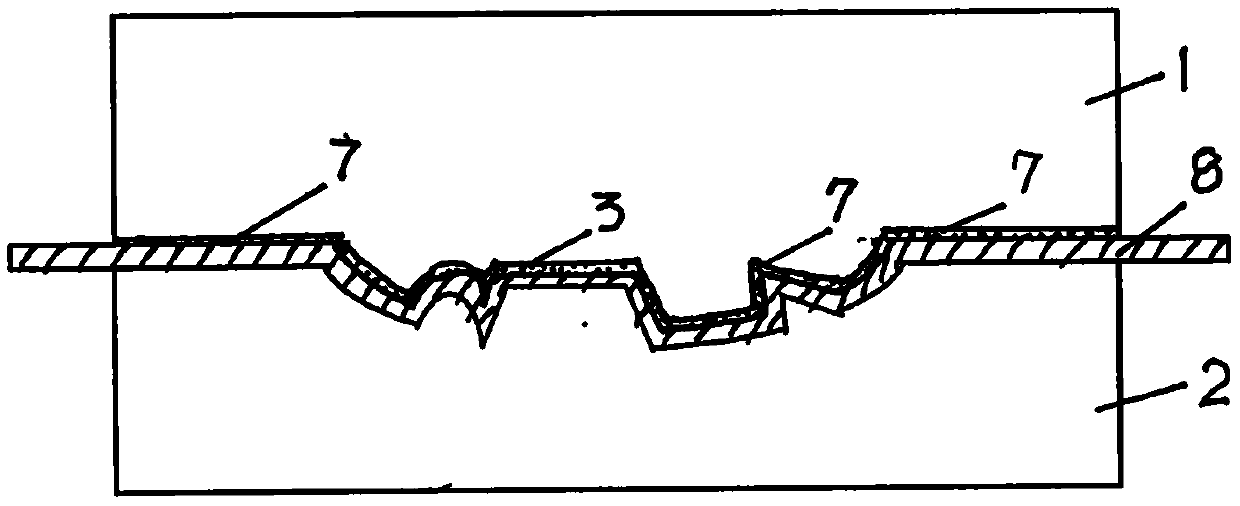

[0054] Embodiment 2, the hot pressing mold that the whole surface of mold steel upper mold has low thermal conductivity layer

[0055] Such as figure 2 , a hot-pressing mold with a low thermal conductivity layer on the surface, including a matching die steel upper die 1 and a die steel lower die 2, the die steel upper die 1 is located above the die steel lower die 2, and all of the die steel upper die 1 The contact surface is provided with a low thermal conductivity surface layer 3 with a thermal conductivity lower than that of the mold steel body, that is, a low-temperature surface layer lower than the temperature of the mold steel body is provided on all contact surfaces of the mold steel lower die 2 . The low thermal conductivity surface layer 3 is a low thermal conductivity material film layer 7, a fluorine rubber sheet layer, and the thermal conductivity is 0.300 / W / m°C.

Embodiment 3

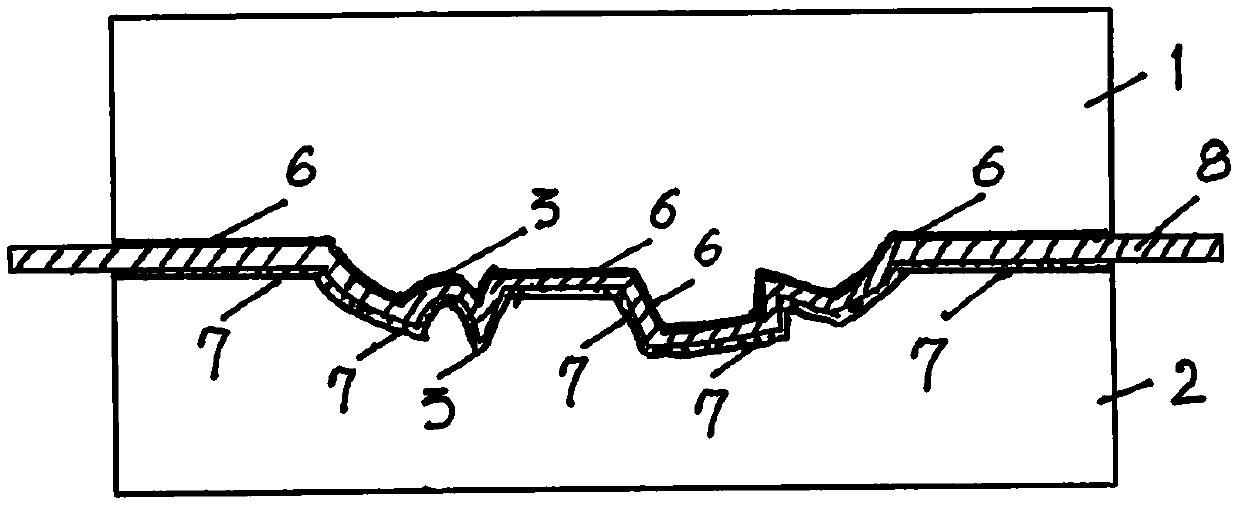

[0056] Embodiment 3, the mold steel upper mold and the mold steel lower mold all have the hot pressing mold of low thermal conductivity layer on the surface

[0057] Such as image 3 , a hot-pressing mold with a low thermal conductivity layer on the surface, including a matching die steel upper die 1 and a die steel lower die 2, the die steel upper die 1 is located above the die steel lower die 2, and all of the die steel upper die 1 The contact surface is provided with a low thermal conductivity surface layer 3 with a thermal conductivity lower than that of the mold steel body, that is, a low-temperature surface layer lower than the temperature of the mold steel body is provided on the entire contact surface of the upper die 1 of the mold steel, and the low thermal conductivity surface layer 3 is low thermal conductivity. Material Coating 6 Nitrile rubber coating, the thermal conductivity is 0.250 / W / m℃.

[0058] And all the contact surfaces of the mold steel lower mold 2 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com