Preparation method of kitchen waste based composite defect type conductive porous carbon material

A technology of porous carbon materials and kitchen waste, applied in the direction of carbon preparation/purification, hybrid capacitor electrodes, etc., can solve the problems that the degree of improvement cannot meet actual needs, limit large-scale development and utilization, and limit industrialization development, etc., to achieve improved thermodynamics Degradability, good energy storage effect, and superior conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

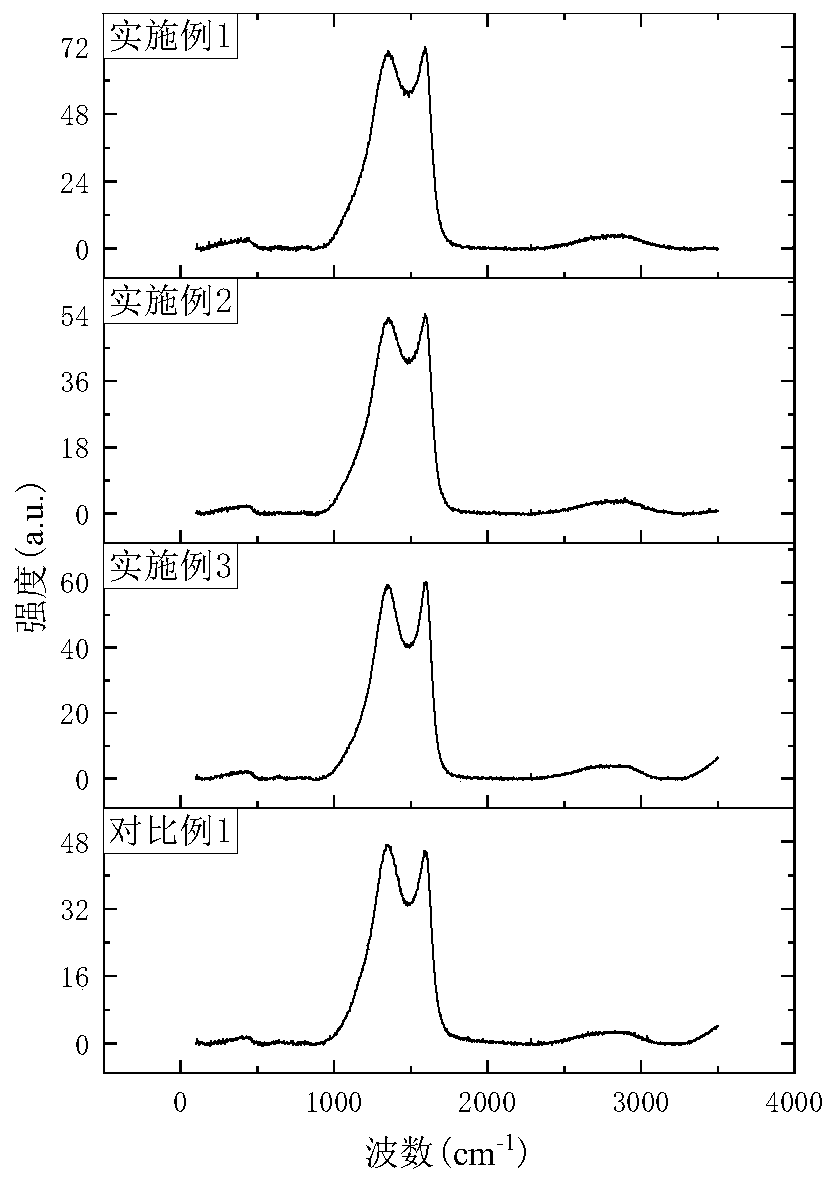

Embodiment 1

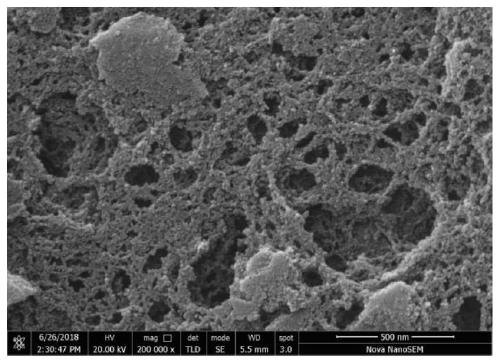

[0032] (1) After sorting out plastics, chopsticks, facial tissues, bones and other impurities in the food waste, use a meat grinder to grind the food waste into a paste;

[0033] (2) Put the crushed food waste into a special freezer, adjust the freezing temperature to -18°C, and freeze for 48 hours;

[0034] (3) put the frozen food waste into an oven for drying, and grind it into powder with a particle size of 75-150 μm;

[0035] (4) Fill a porcelain crucible with a lid with crushed kitchen waste and place it in a box-type resistance furnace. The pyrolysis time is 90 minutes, the pyrolysis temperature is 550°C, and the heating rate is 10°C / min;

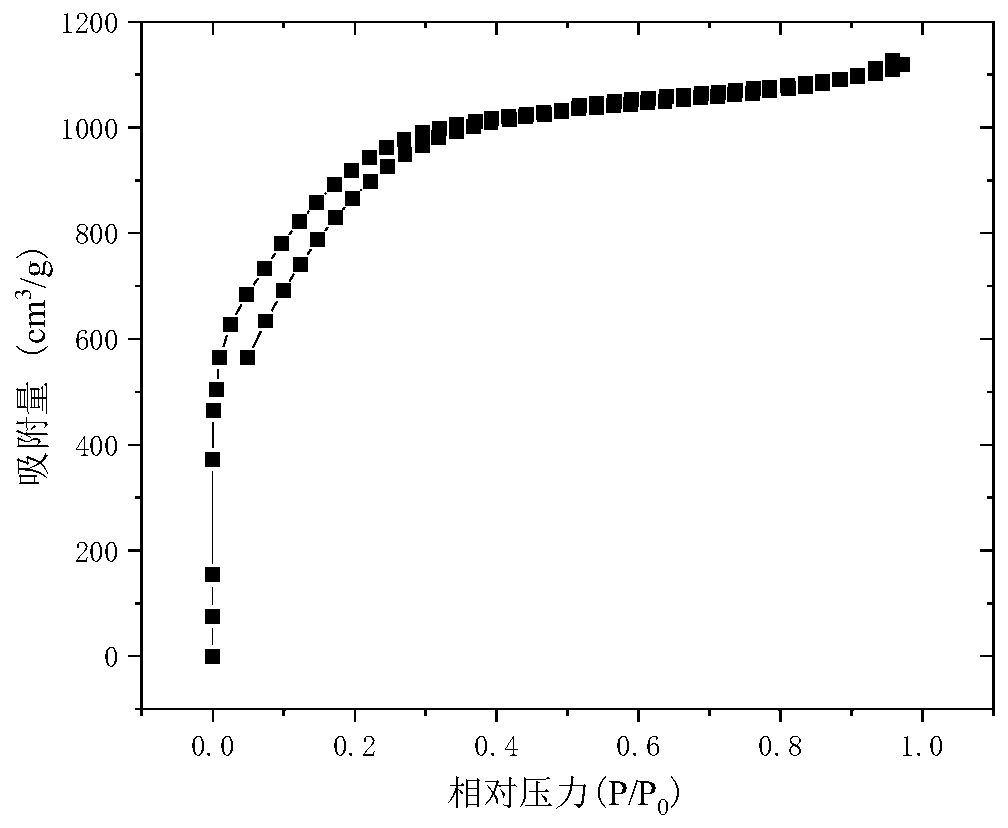

[0036] (5) Add 3 times the amount of KOH to impregnate the carbonized carbonized material, then adjust the activation time to 60 minutes, the melting temperature to 400°C, the activation temperature to 800°C, and the heating rate to 10°C / min;

[0037] (6) After the reaction is completed, cool the sample to room temperature, take it o...

Embodiment 2

[0039] (1) After sorting out plastics, chopsticks, facial tissues, bones and other impurities in the food waste, use a meat grinder to grind the food waste into a paste;

[0040] (2) Put the crushed food waste into a special freezer, adjust the freezing temperature to -18°C, and freeze for 48 hours;

[0041] (3) put the frozen food waste into an oven for drying, and grind it into powder with a particle size of 75-150 μm;

[0042] (4) Fill a porcelain crucible with a lid with crushed kitchen waste and place it in a box-type resistance furnace. The pyrolysis time is 90 minutes, the pyrolysis temperature is 550°C, and the heating rate is 10°C / min;

[0043] (5) Add the carbonized carbonized material to 2 times the amount of KOH for impregnation, then adjust the activation time to 60 minutes, the melting temperature to 400°C, the activation temperature to 800°C, and the heating rate to 10°C / min;

[0044] (6) After the reaction is completed, cool the sample to room temperature, tak...

Embodiment 3

[0046] (1) After sorting out plastics, chopsticks, facial tissues, bones and other impurities in the food waste, use a meat grinder to grind the food waste into a paste;

[0047](2) Put the crushed food waste into a special freezer, adjust the freezing temperature to -18°C, and freeze for 48 hours;

[0048] (3) put the frozen food waste into an oven for drying, and grind it into powder with a particle size of 75-150 μm;

[0049] (4) Fill a porcelain crucible with a lid with crushed kitchen waste and place it in a box-type resistance furnace. The pyrolysis time is 90 minutes, the pyrolysis temperature is 550°C, and the heating rate is 10°C / min;

[0050] (5) Add the carbonized carbonized material to 1 times the amount of KOH for impregnation, then adjust the activation time to 60 minutes, the melting temperature to 400°C, the activation temperature to 800°C, and the heating rate to 10°C / min;

[0051] (6) After the reaction is completed, cool the sample to room temperature, take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com