Down-hole annular blowout preventer experiment bench

A blowout preventer and test bench technology, which is applied in the direction of instruments, machine/structural component testing, measuring devices, etc., to achieve the effects of timely unsealing, simple structure, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

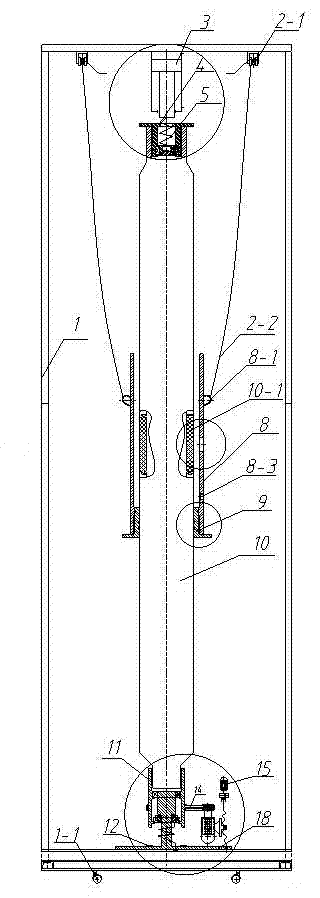

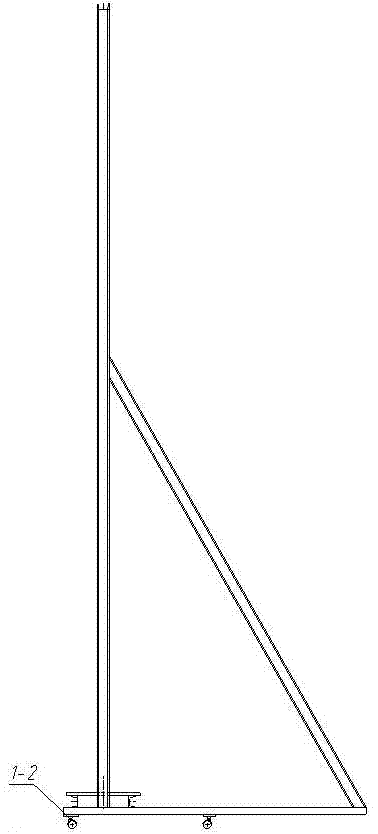

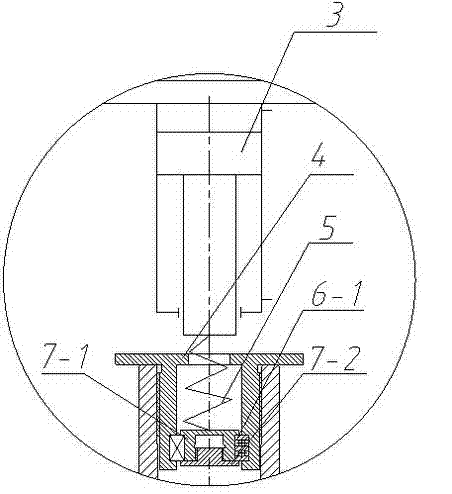

[0028] Downhole annular blowout preventer test bench of the present invention, its embodiment 1 is as figure 1 As shown, it includes frame parts such as figure 2 , to test the pressure part of the rubber cartridge such as Figure 4 , Figure 5 , the part of the pressurization device such as image 3 and drive the BOP rotating part such as Figure 6 , Figure 7 , Figure 8 composed of; frame parts (such as figure 2 shown) includes I-beam (1), rollers (1-1), roller mounting plate (1-2), the main body of the frame is rectangular, in order to strengthen the strength of the frame and utilize the stability of the triangle, the height of the frame 1 / 2 is provided with a tripod, and the material of the tripod is still I-beam (1).

[0029] The pressure part of the test rubber cartridge includes a pulley block (2-1), a cable (2-2), a casing (8), a joint under the casing (9), a cable hook (8-1), and an observation hole (8-2 ), the high-pressure liquid inlet (8-3), the seal (9-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com