Hydraulic flotation equipment and dredging method thereof

A hydraulic and flotation technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of tailings clogging, affecting the timely discharge of tailings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

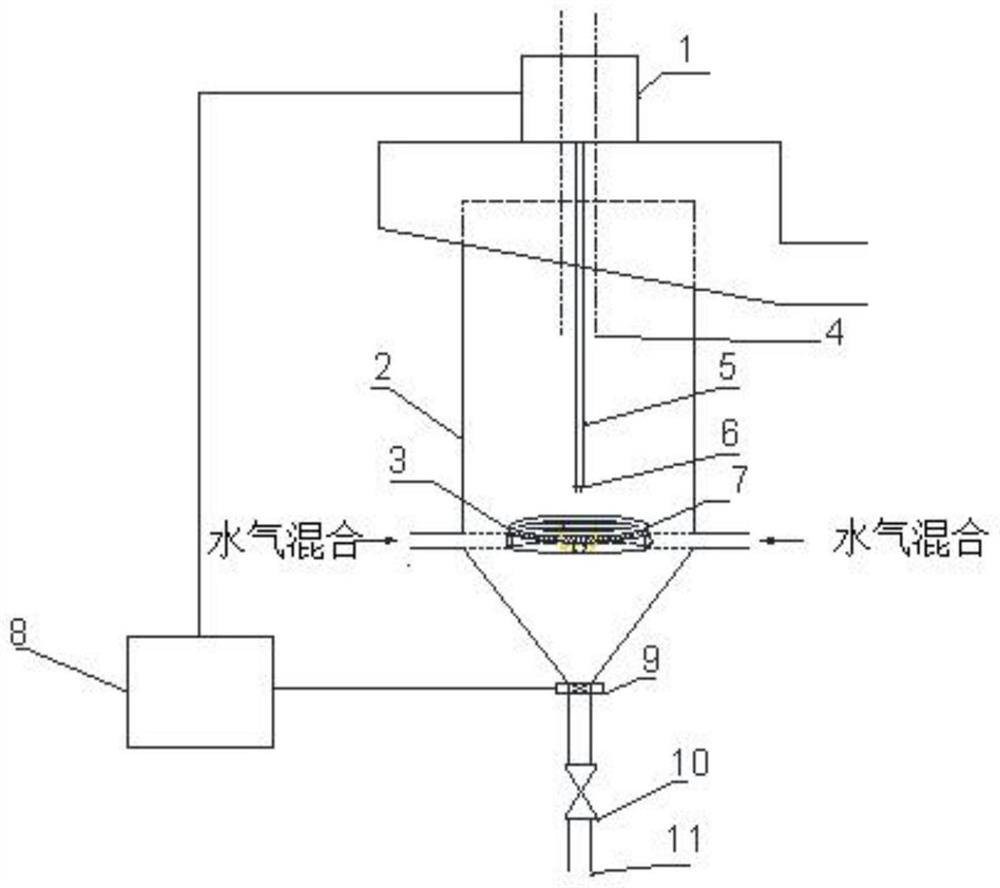

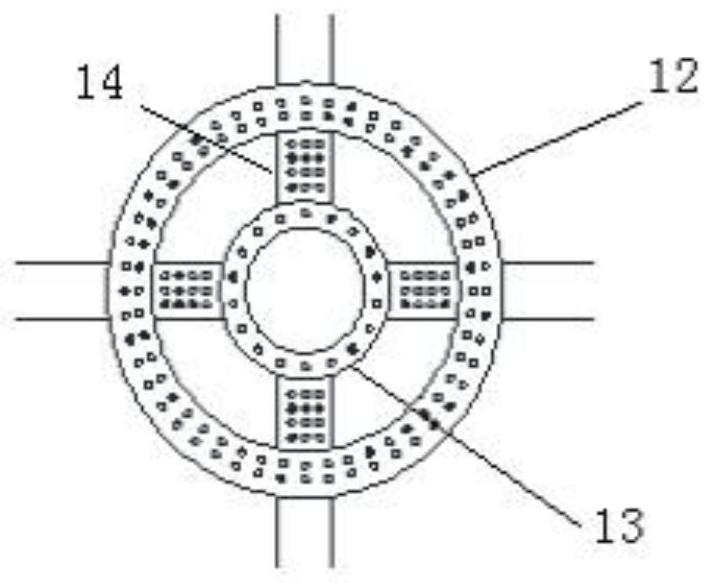

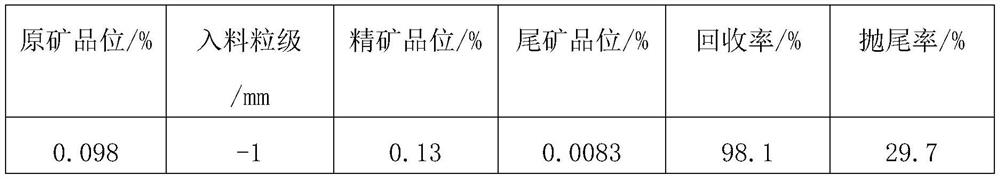

[0057] A specific embodiment of the present invention discloses a separation and recovery process for tailings (hereinafter referred to as raw ore) of a certain molybdenum industry using the above-mentioned hydraulic flotation equipment, wherein the thickness of the perforated plate is 2mm, and the separation and recovery process Including the following steps:

[0058] Step 1: Add foaming agent MIBC (20ppm) to the water-air mixture in advance, adjust the ratio of the water velocity and gas velocity of the water-air mixture injected into the annular cavitation device 7, form an ascending water flow, and generate cavitation bubbles;

[0059] Step 2: Put the raw ore pulp into the hydraulic flotation machine 2 from the feed pipe 4, the coarse coal slime in the pulp completes the interference settlement in the hydraulic flotation machine, and the coarse grain concentrate is discharged from the overflow port of the hydraulic flotation machine 2 discharge; the coarse gangue in the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com