Pallet And Method For Manufacturing The Same

a technology of pallets and pallets, applied in the field of pallets, can solve the problems of higher costs, more expensive pallets made of plastic and metal, and a disposal problem for plastic and metal pallets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] A biodegradable pallet and a method for manufacturing the same are provided. In the following description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. It will be understood, however, to one skilled in the art, that the present invention may be practised without some or all of these specific details. In other instances, well known process operations have not been described in detail in order not to unnecessarily obscure the present invention.

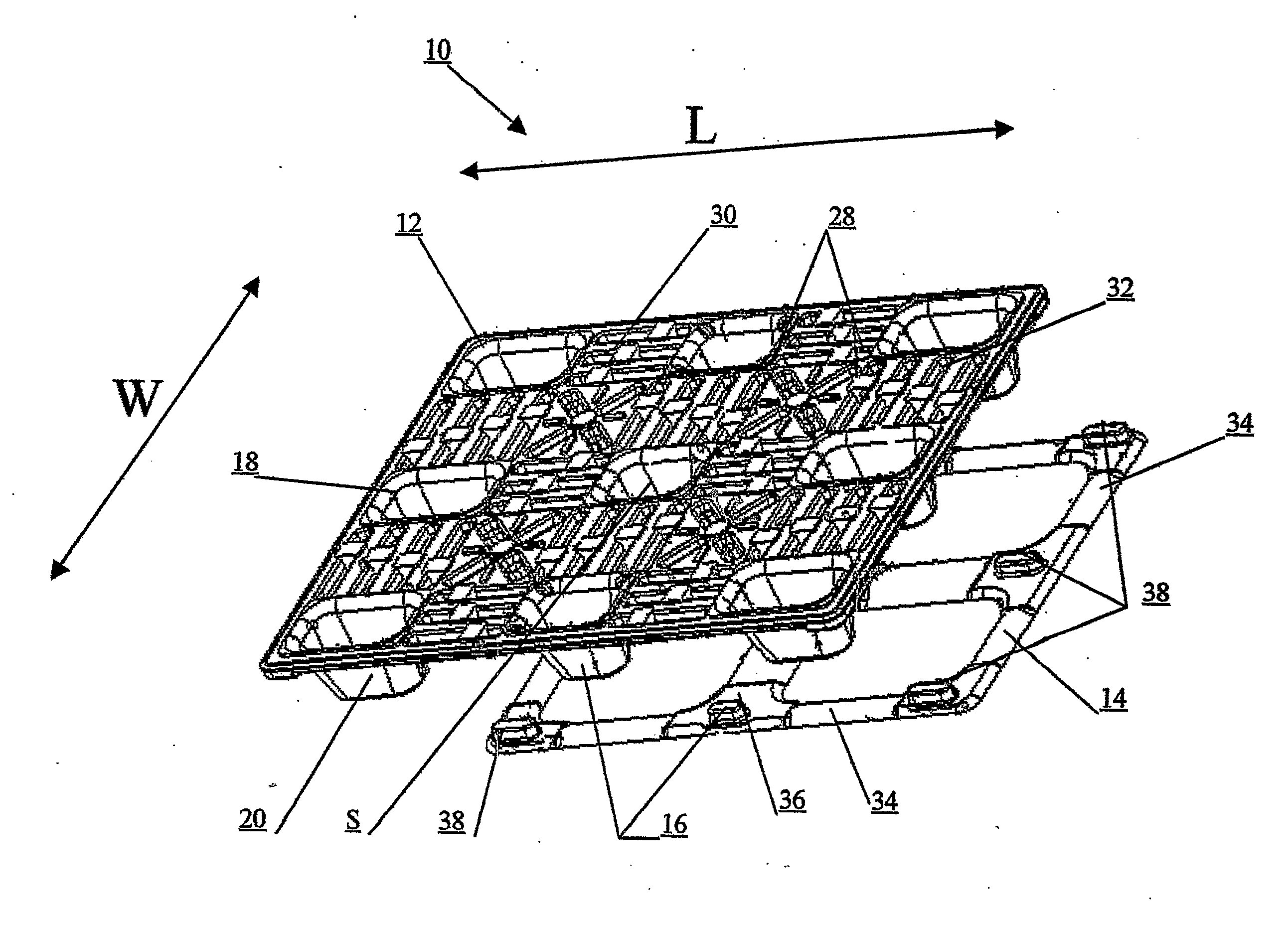

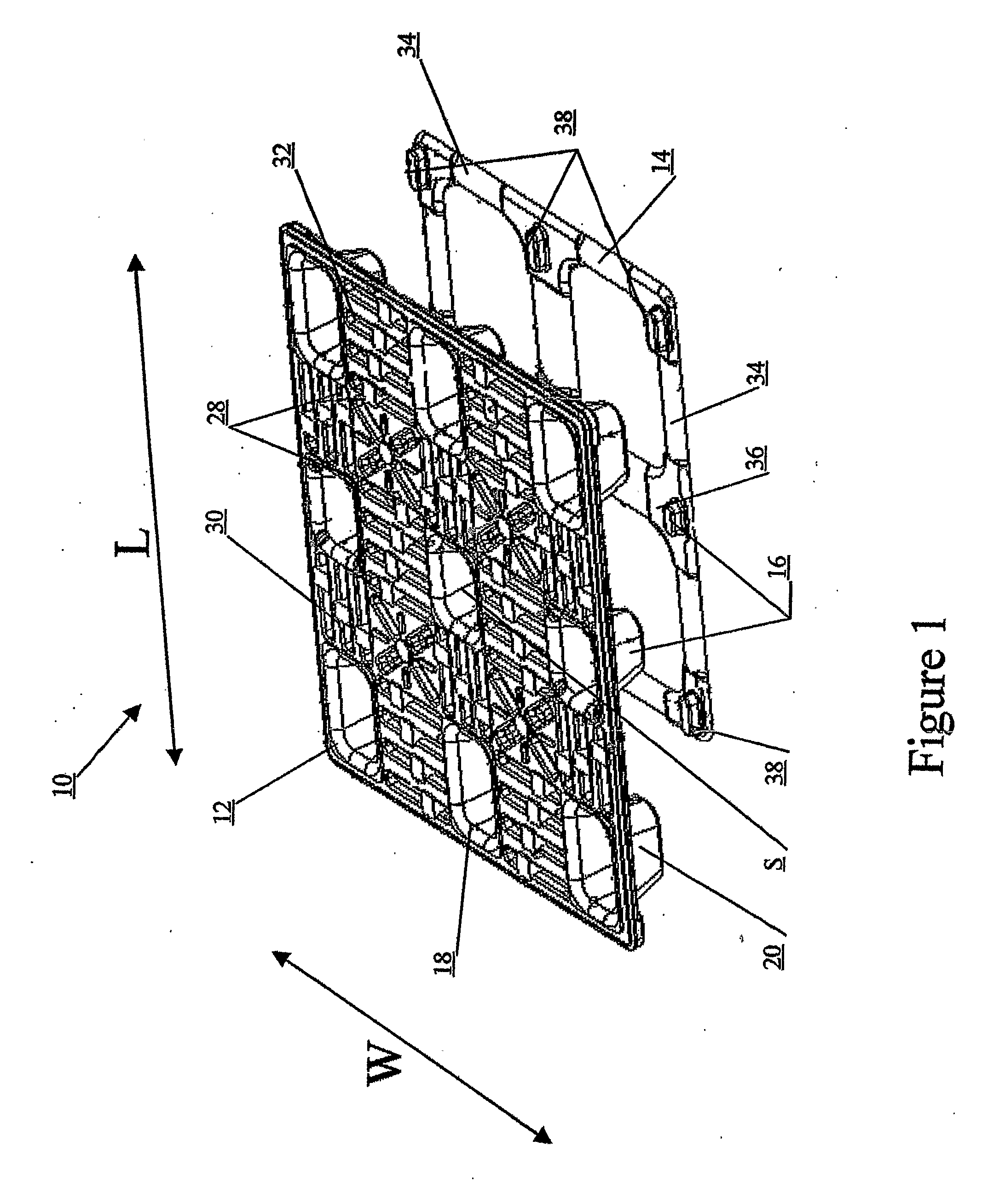

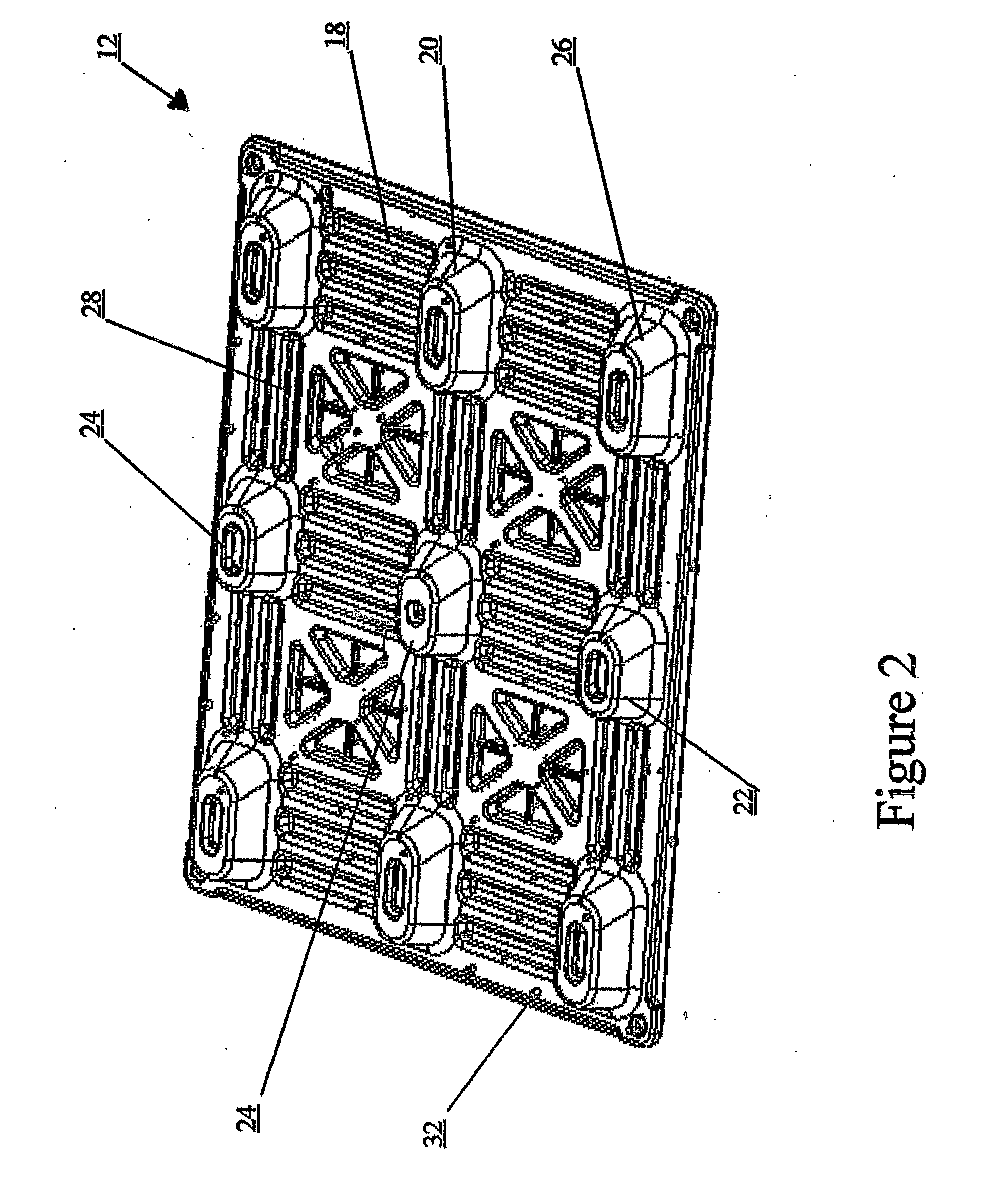

[0048]FIG. 1 illustrates a perspective view of a biodegradable pallet 10 in accordance with one embodiment of the present invention. Pallet 10 comprises a pallet body 12 that is reinforced when coupled to an attachable skid 14 by an interlocking means 16, Skid 14 enhances the rigidity and stability of pallet 10 and conforms pallet 10 to the specifications stipulated for material handling applications using various types of conveyor systems such as, for example, forklifts, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com