Pre-filling self expansion packer for well completion

A self-expanding and packer technology, applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problems of long setting time and complicated well completion process, and achieve short setting time, The effect of shortening the completion time and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

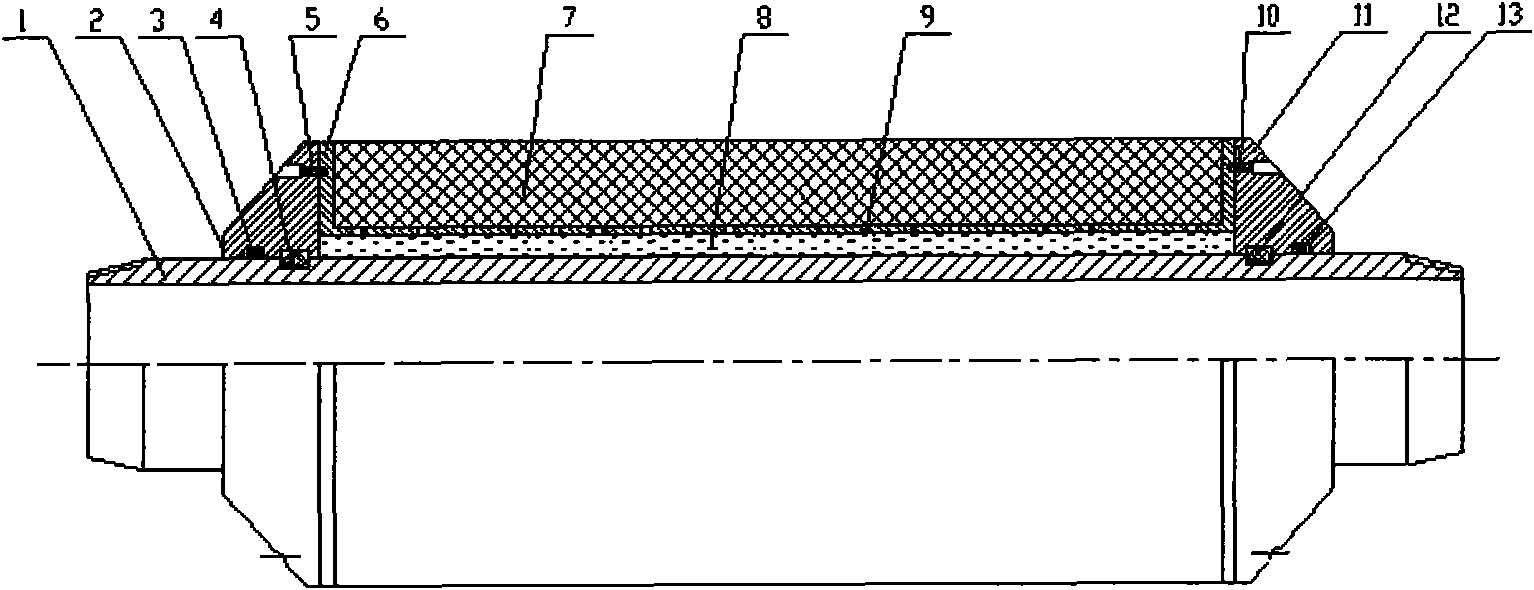

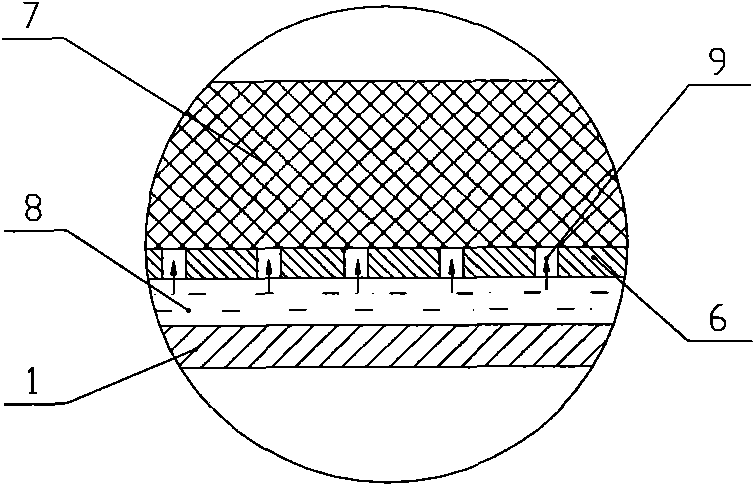

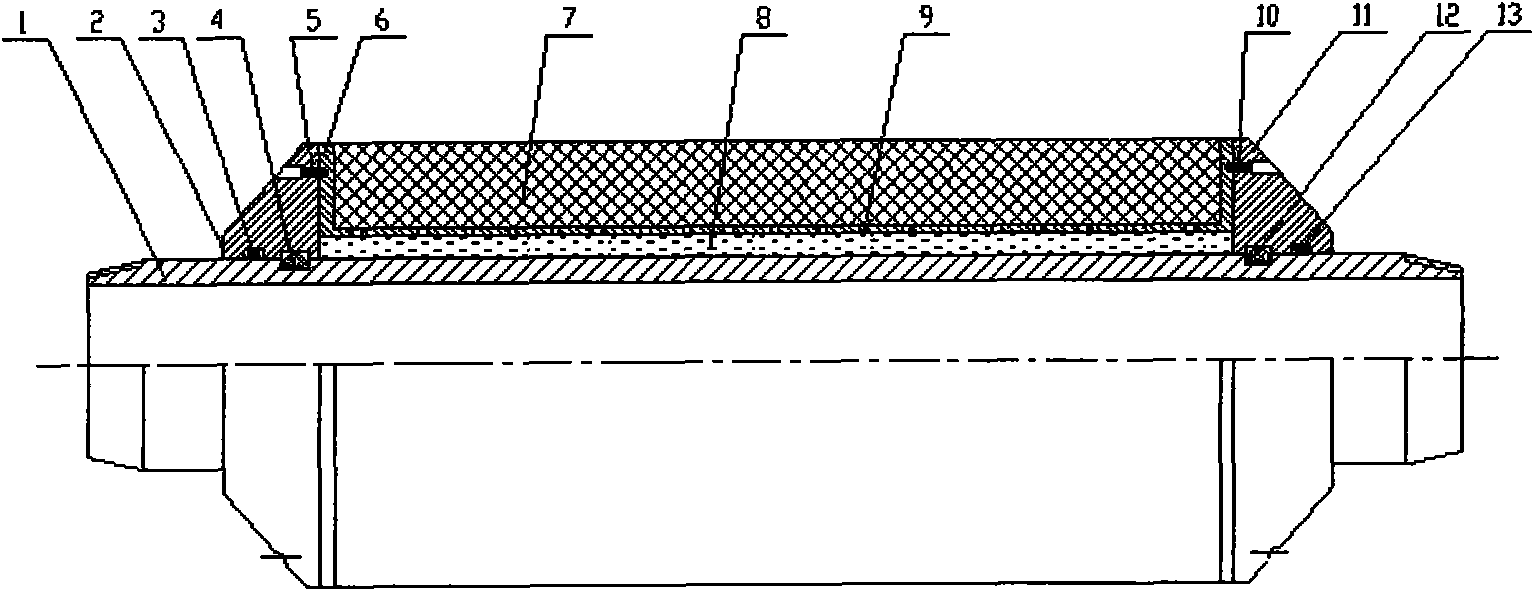

[0010] A pre-packed self-expandable packer for oilfield well completion provided by the present invention consists of a base pipe 1, a stop ring A2, an O-ring A3, a snap ring A4, a screw A5, an oil-expandable rubber 7, an expansion medium 8, a belt Hole spacer 6, limit ring B11, O-ring B13, snap ring B12, and screw B10; limit ring A2 and limit ring B11 are respectively located at the two ends of the base pipe 1, and are fixed in the groove on the outer wall of the base tube 1 The inner snap ring A4 and snap ring B12 are snapped into the grooves on the inner wall of the limit ring A2 and the limit ring B1 to be fixed, and the space between the limit ring A2, the inner wall of the limit ring B11 and the outer wall of the base pipe 1 is composed of O-rings A3, O-ring B13 is sealed; the spacer with holes 6 is set on the outer wall of the base pipe 1, between the limit ring A2 and the limit ring B11, and is fixed on the limit ring A2 and the limit ring B11 by screws A5 and B10, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com