Method of monitoring coal mining solid pack pressure

A technology of solid filling and pressure monitoring, which is applied to filling materials, mining equipment, earth square drilling and mining, etc., to achieve the effects of simple method, improved filling effect and wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

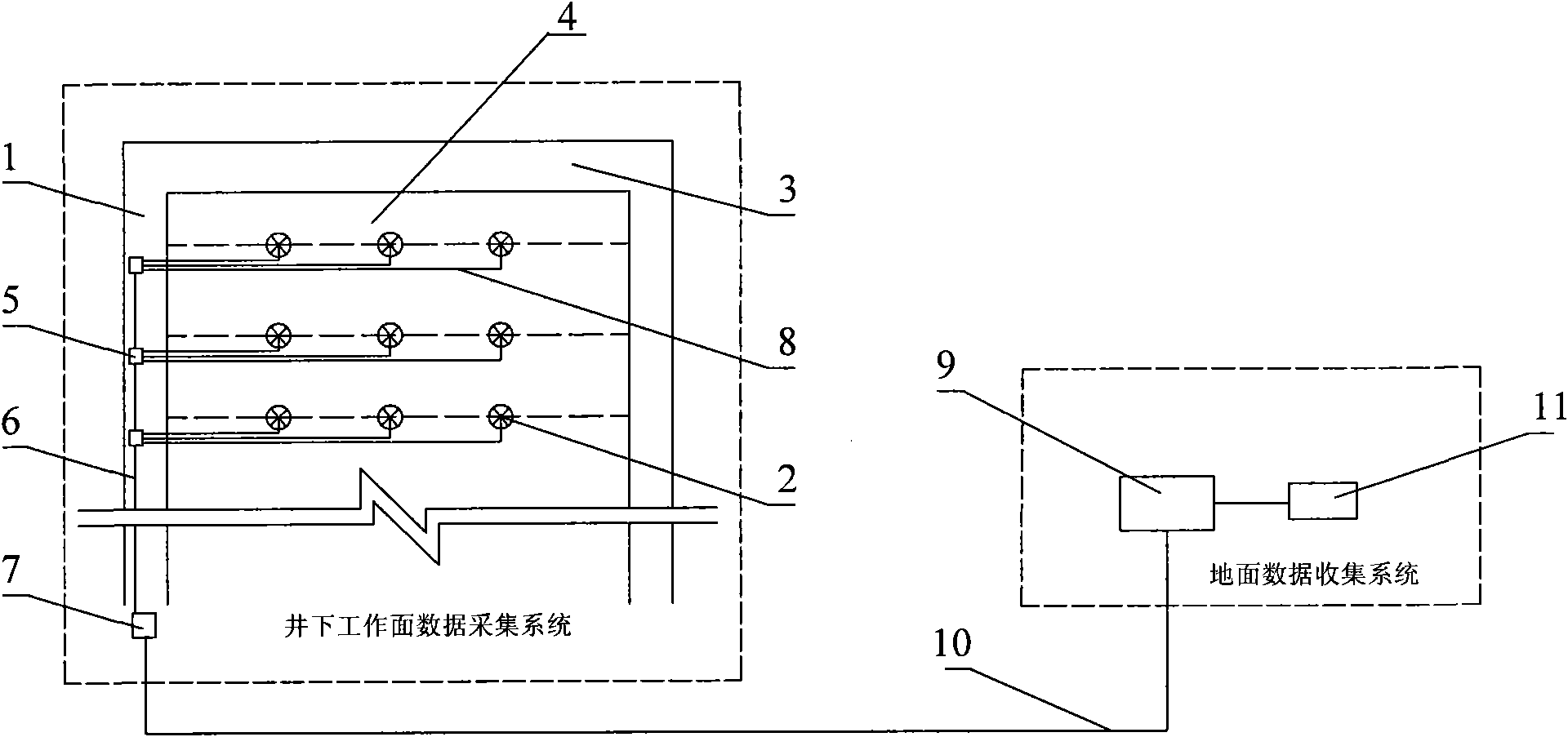

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0015] The coal mining solid filling body pressure monitoring method of the present invention: in the pre-filled goaf 4 advanced by the filling and mining working face, 3 rows of filling body pressure monitors 2 are arranged, and each row is arranged with 3, and the pressure monitor 2 between the rows The distance is 25m-35m, the distance from the first row to the cutting hole 3 is about 15m, the average buried depth of the filling mining face is 350m, the face length is 50m, and the advancing length is 460m. According to the actual needs of the site, the filling body pressure monitor 2 can be arranged in 2 to 4 rows, and each row is buried with 3 to 6 pieces at intervals, and each filling body pressure monitor 2 in each row is connected with a pressure monitor communication line 8 In the junction box 5 of the coal transportation lane 1, in order to protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com