Hydraulic fracturing system for driving plunger pump by using turbine engine

A turbine engine and hydraulic fracturing technology, applied in the field of hydraulic fracturing systems, to save costs, increase stability and safety, and reduce the overall center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

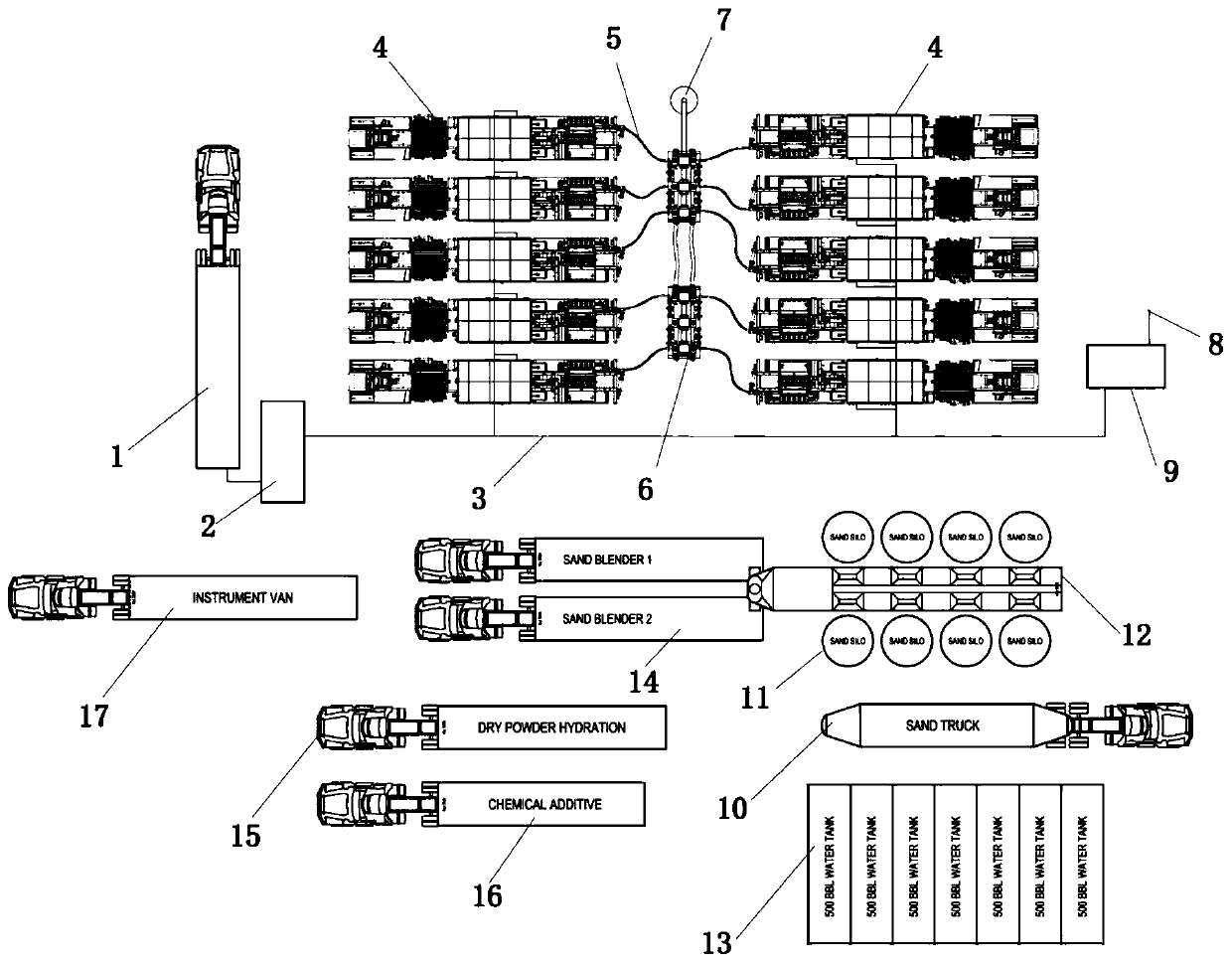

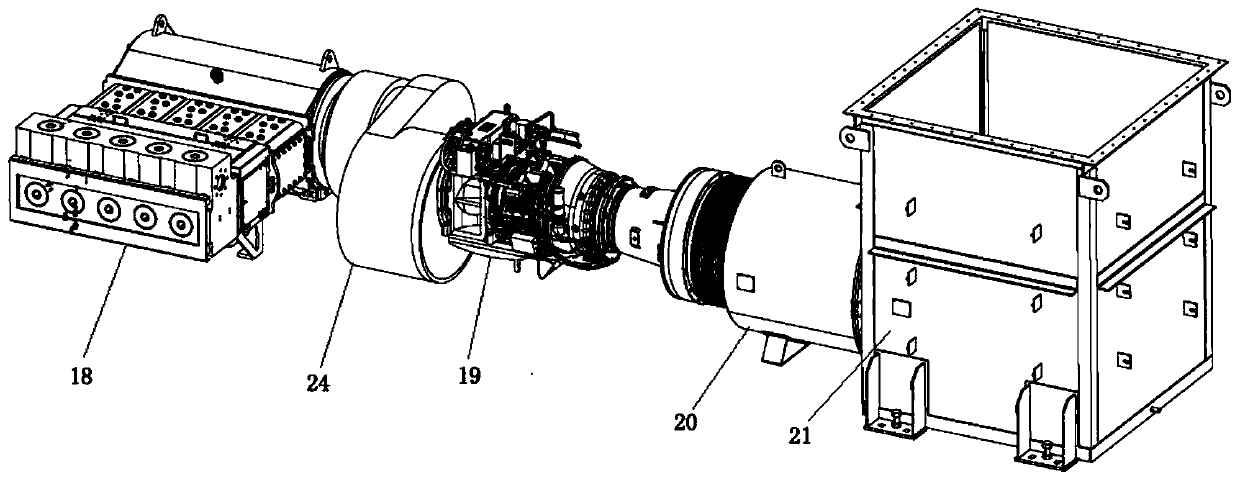

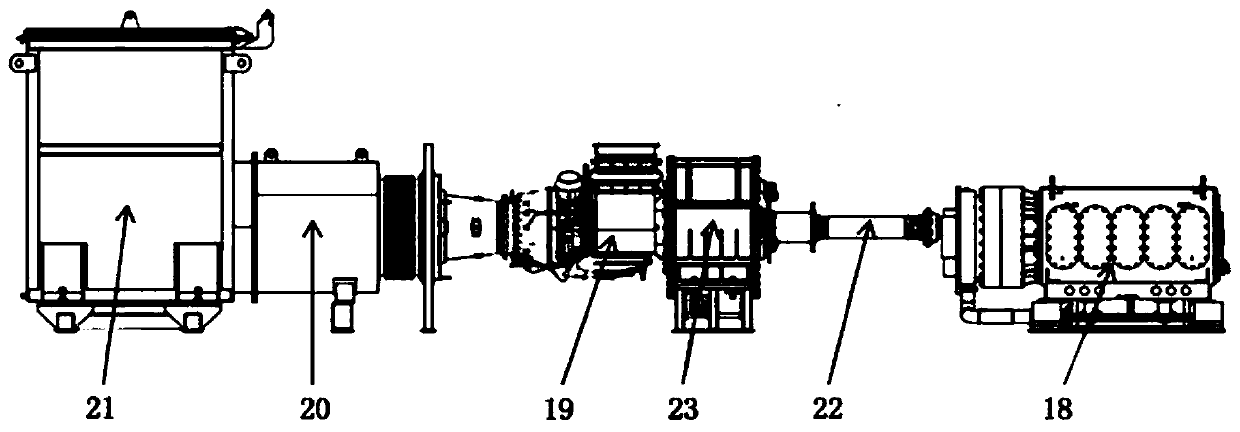

[0030] Such as Figures 1 to 3 As shown, a hydraulic fracturing system utilizing a turbine engine to drive a plunger pump includes a connecting pipeline 5, fracturing equipment, a high and low pressure manifold 6, a mixing equipment 15 and a sand mixing equipment 14, and the mixing equipment 15 uses For the mixing of fracturing base fluid in the hydraulic fracturing system, the sand mixing equipment 14 provides fracturing base fluid and fracturing proppant for the high and low pressure manifold 6, and one end of the high and low pressure manifold 6 passes through the connecting pipeline 5 It is connected with the fracturing equipment, and the other end of the high and low pressure manifold 6 is connected with the wellhead 7. The power source of the fracturing equipment is a turbine engine 19, and the plunger pump 18 is driven by the turbine engine 19. Compared with the traditional The fracturing equipment powered by a diesel engine has a large power-to-volume ratio and a small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com