Light five-cylinder plunger pump

A cylinder rod and plug pump technology, applied in the field of light-duty five-cylinder plunger pumps, can solve the problem that the output pressure and flow do not meet the requirements of the cementing operation conditions, the weight and power are satisfied at the same time, and the total weight of the cementing vehicle does not meet the requirements. and other problems, to achieve the effect of weight reduction, load increase, and self-weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

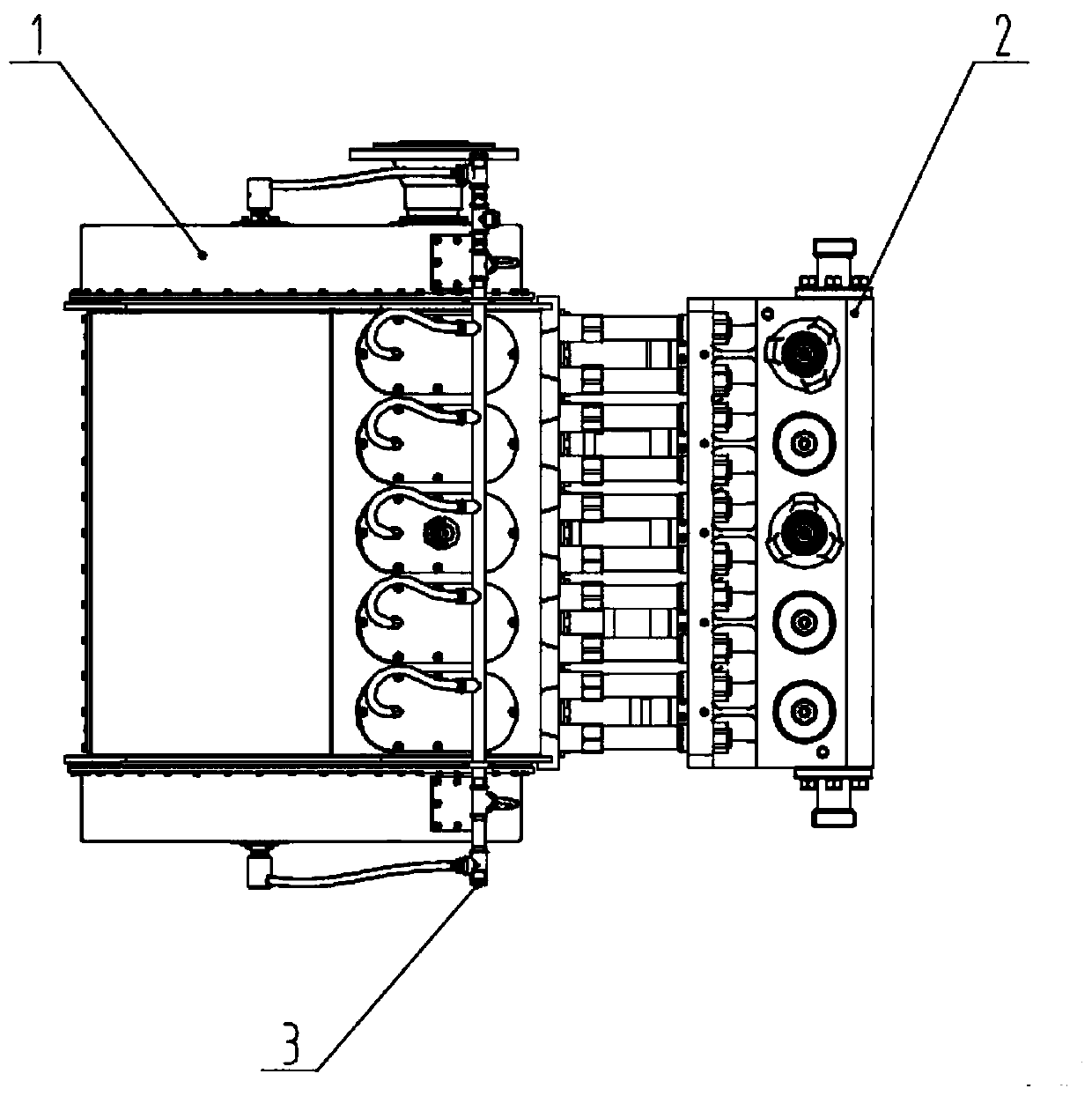

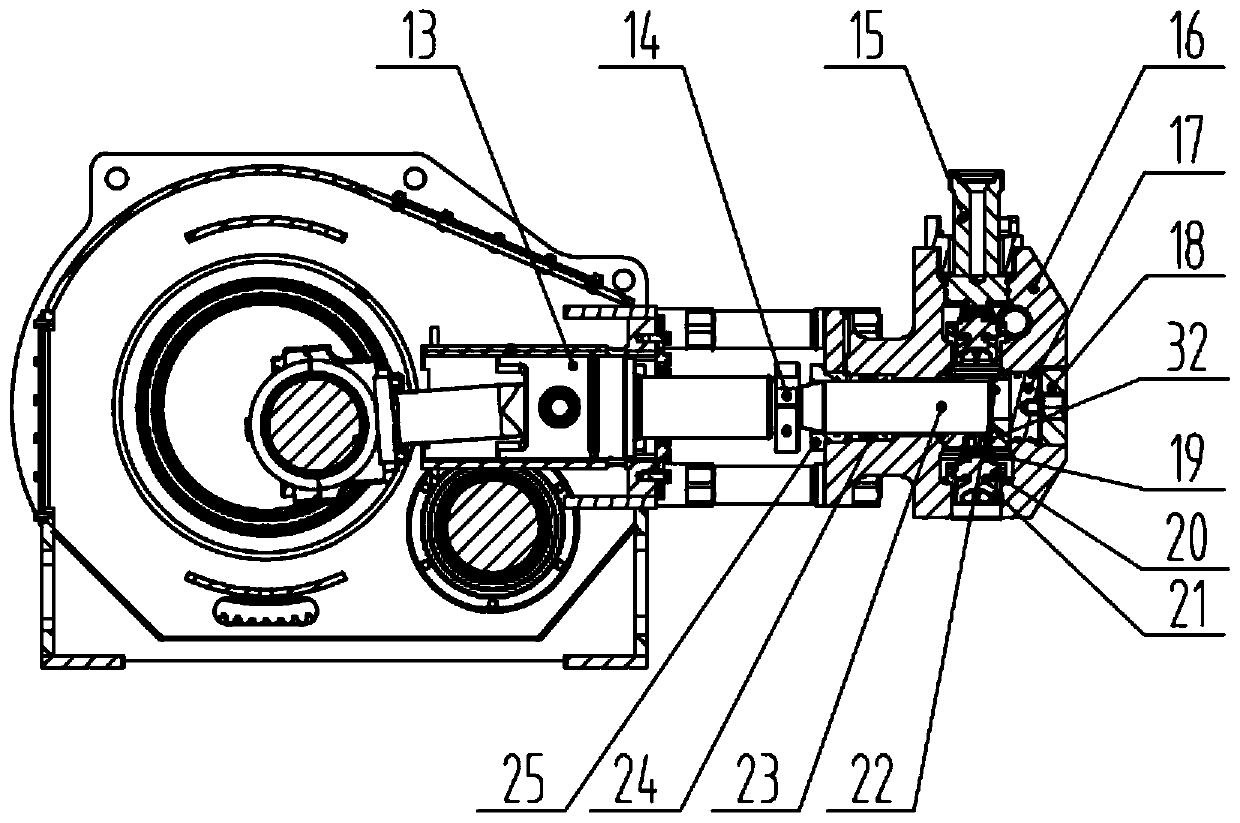

[0020] like Figure 1-5 As shown, a light-duty five-cylinder plunger pump includes a power end assembly 1 , a fluid end assembly 2 , and a lubricating pipeline 3 . The input end of the power end assembly 1 is connected to the power source, the output end of the power end assembly 1 is connected to the fluid end assembly 2, and the lubricating pipeline 3 is connected to the power end assembly 1 for feeding the power end assembly. 1 lubrication.

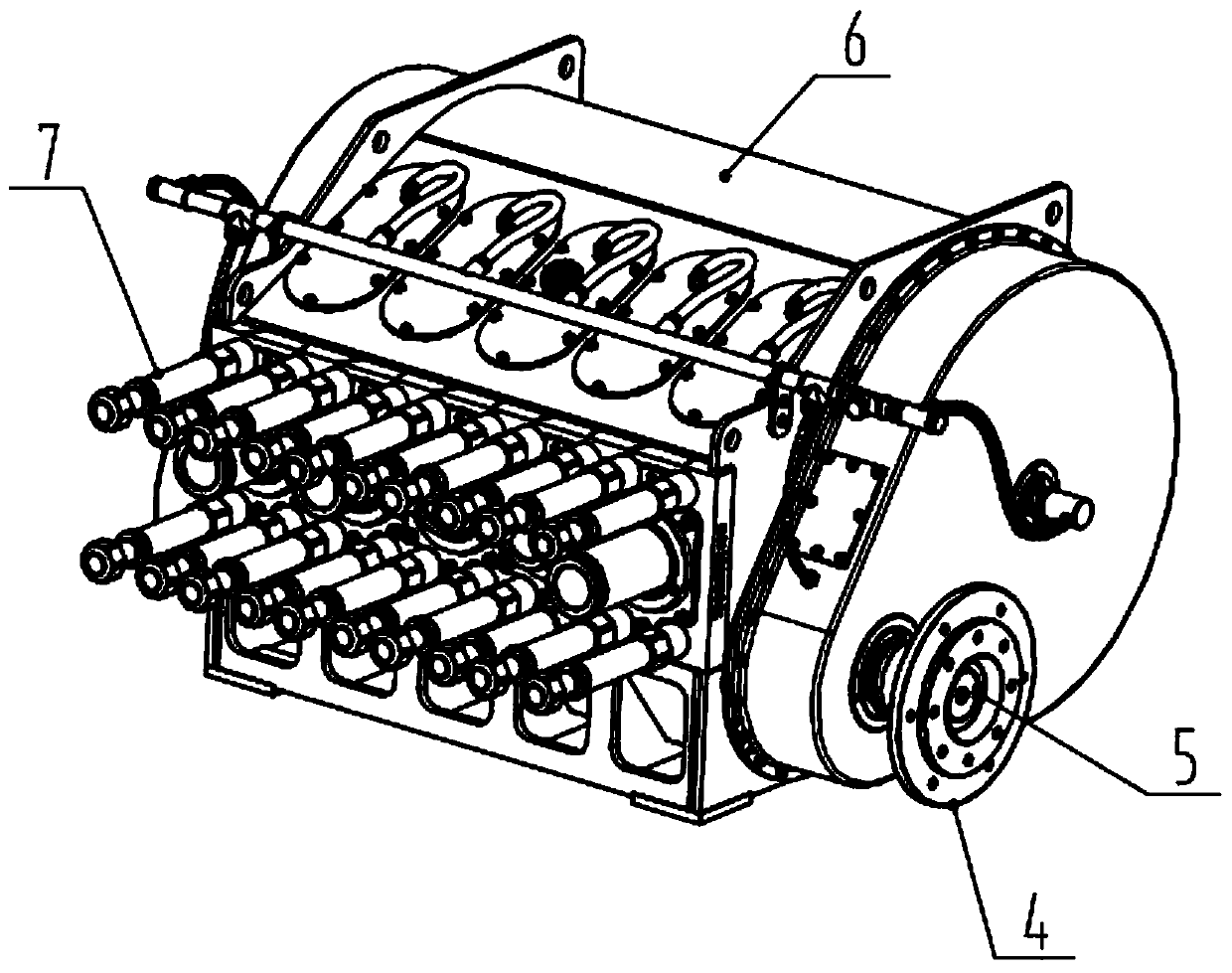

[0021] The power end assembly 1 includes a power end housing 6 and connecting pieces inside the power end housing 6 . The connecting parts include a gear pair assembly, a crankshaft 8 and a connecting rod crosshead assembly 13 connected in sequence. Crankshaft 8 comprises crank neck and crank throw, and crank neck is fixedly connected with crank throw. There are six curved necks and five curved crutches. Five bellcranks start from the input end of the crankshaft 8 close to the power end assembly 1, and are successively named as bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com