Plunger pump used for pumping ultralow-temperature liquid nitrogen

An ultra-low temperature, plunger pump technology, applied in the field of plunger pumps, can solve the problems of liquid nitrogen easily endothermic vaporization and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

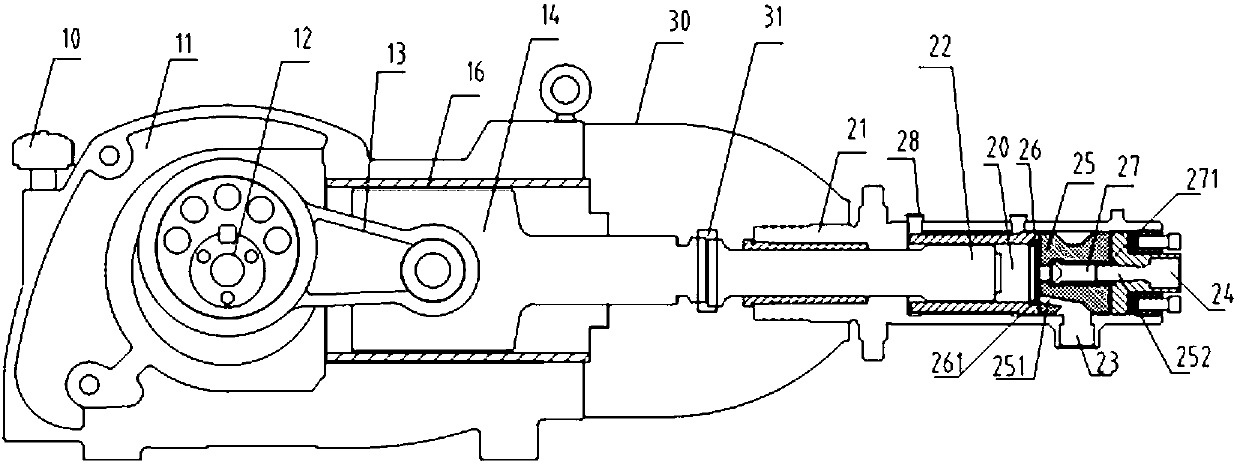

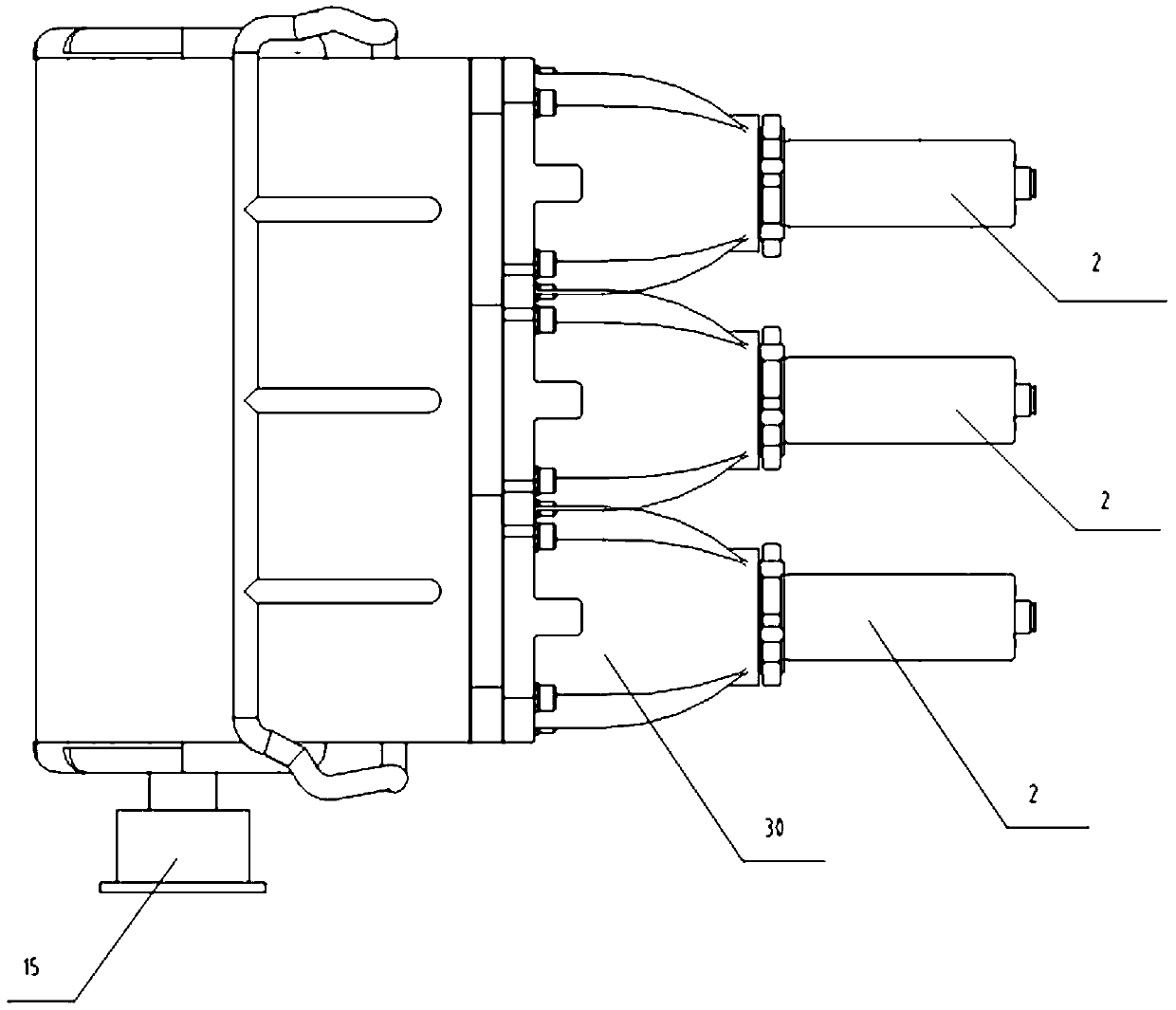

[0014] like figure 1 and figure 2 As shown, a plunger pump for pumping ultra-low temperature liquid nitrogen is mainly composed of two parts, a cold end 2 and a power end. The power end is mainly used to convert the rotary motion transmitted by the engine into reciprocating linear motion. The cold end 2 is the core component of the liquid nitrogen pump, and its interior is professionally designed, and its main function is to achieve low-pressure suction and high-pressure discharge of liquid nitrogen.

[0015] The power end includes a power end housing 11, a crankshaft 12 installed inside the power end housing 11, a connecting rod 13 drivingly connected with the crankshaft 12, and a cross-head tie rod 14 drivingly connected with the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com