A method for preventing plunger pump from pumping out based on monitoring output pressure

A technology for monitoring output and output pressure, which is applied in pump control, pump testing, liquid variable capacity machinery, etc. It can solve the problems of pump emptying, small change, poor stability, etc., and achieve the effect of accurate detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

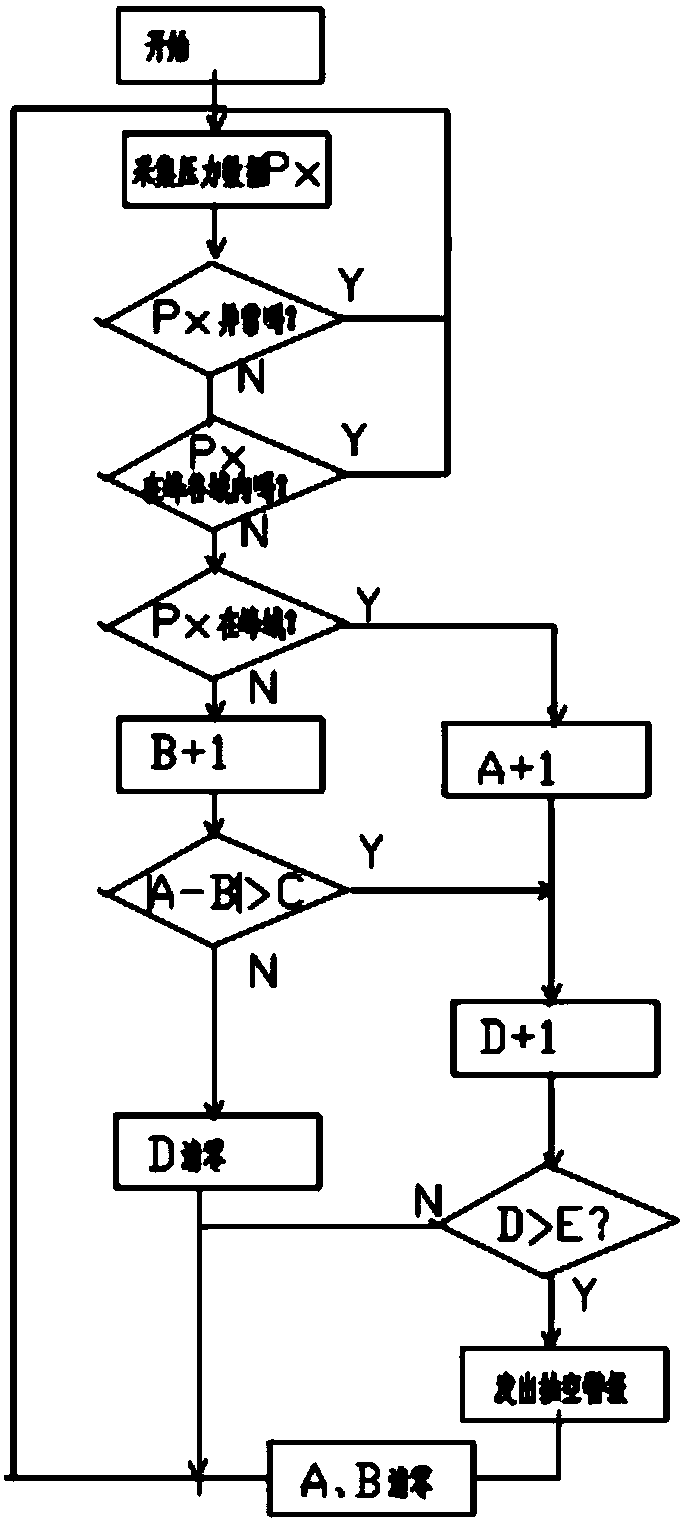

[0039] Such as figure 1 with image 3 As shown, a method based on monitoring the output pressure to prevent the plunger pump from evacuating, including the plunger pump and the outlet pipeline, is characterized in that a pressure data acquisition control device is arranged on the outlet pipeline, and the collected pressure data The processing method is as follows:

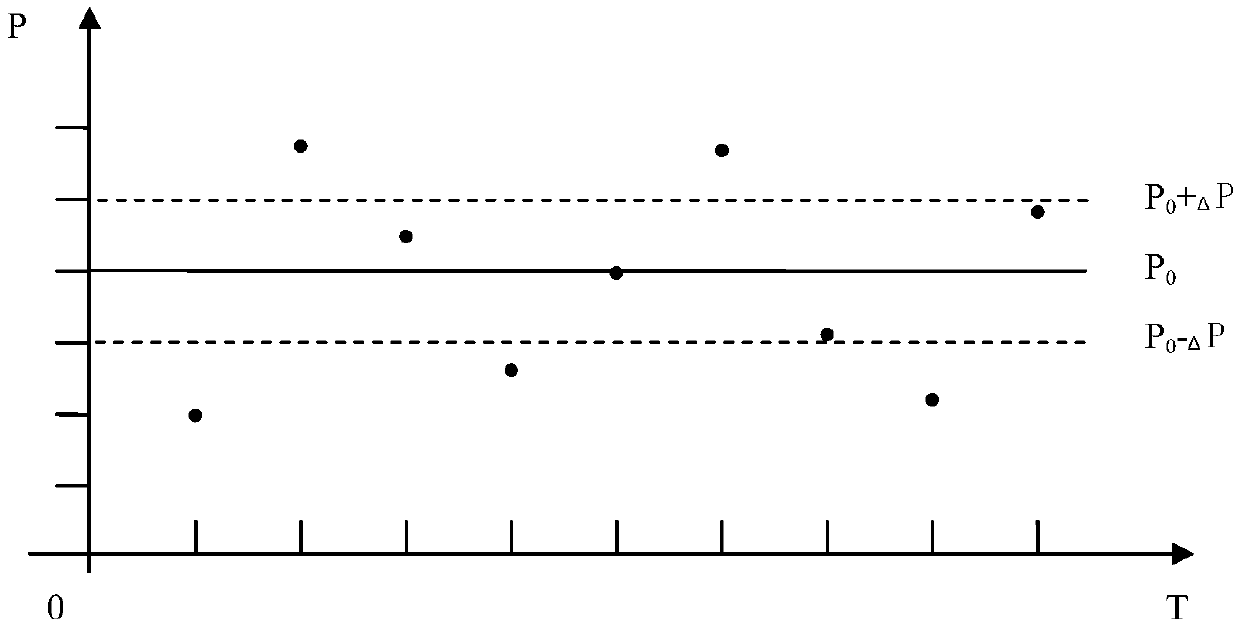

[0040] 1) Obtain the average value of the output pressure P0: continuously collect a set of pressure data, remove the maximum and minimum values, and obtain the average value of the rest to obtain P0; set the output pressure setting tolerance ΔP, then the normal output pressure range is: upper limit P0 +ΔP, above the P0+ΔP line is called the peak region; (meaning that P0 is greater than P0+ΔP); the lower limit P0-ΔP; below the P0-ΔP line is called the valley region (meaning that P0 is less than (P0-ΔP)); and Set the peak area counter A and the valley area counter B respectively; set the allowable difference betwe...

Embodiment 2

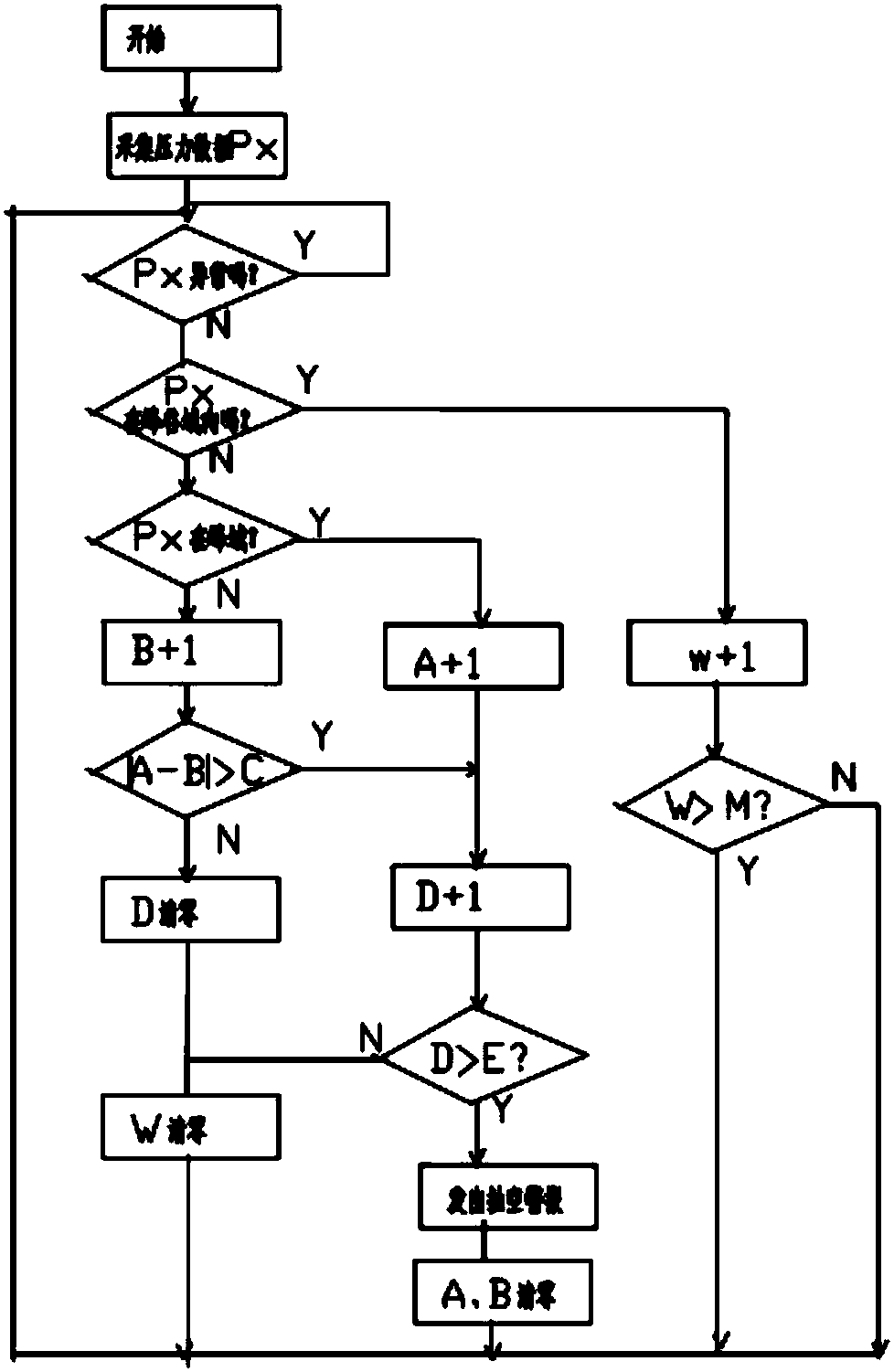

[0055] Such as figure 2 with image 3 As shown, this embodiment is another way of judging evacuation, on the basis of the scheme of embodiment 1: it also includes when the collected pressure data Px is continuously within the peak region and the valley region, but does not appear in the peak region and the valley region Judgment of other pulsating data: that is

[0056] In step 4) above, is Px between the peak domain and the valley domain? If so, then return to step 2) after judging the number of times continuously falling into the peak area and the valley area), set the number of times counter W of Px in the peak area and the valley area, the set limit that the W data reaches The value is M; the specific steps are as follows:

[0057] 8) If Px is outside the peak area and valley area, clear the counter W; if Px is within the peak area and valley area, add 1 to W, and judge whether W is greater than M, if W≥M, Then go to step 9); otherwise go directly to step 2)

[0058] 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com