Long-distance automatic displacement and density automatic control system

A technology of automatic control system and automatic discharge, applied in the direction of electrical program control, pump control, transmission system, etc., can solve the problems of low degree of automation and poor coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

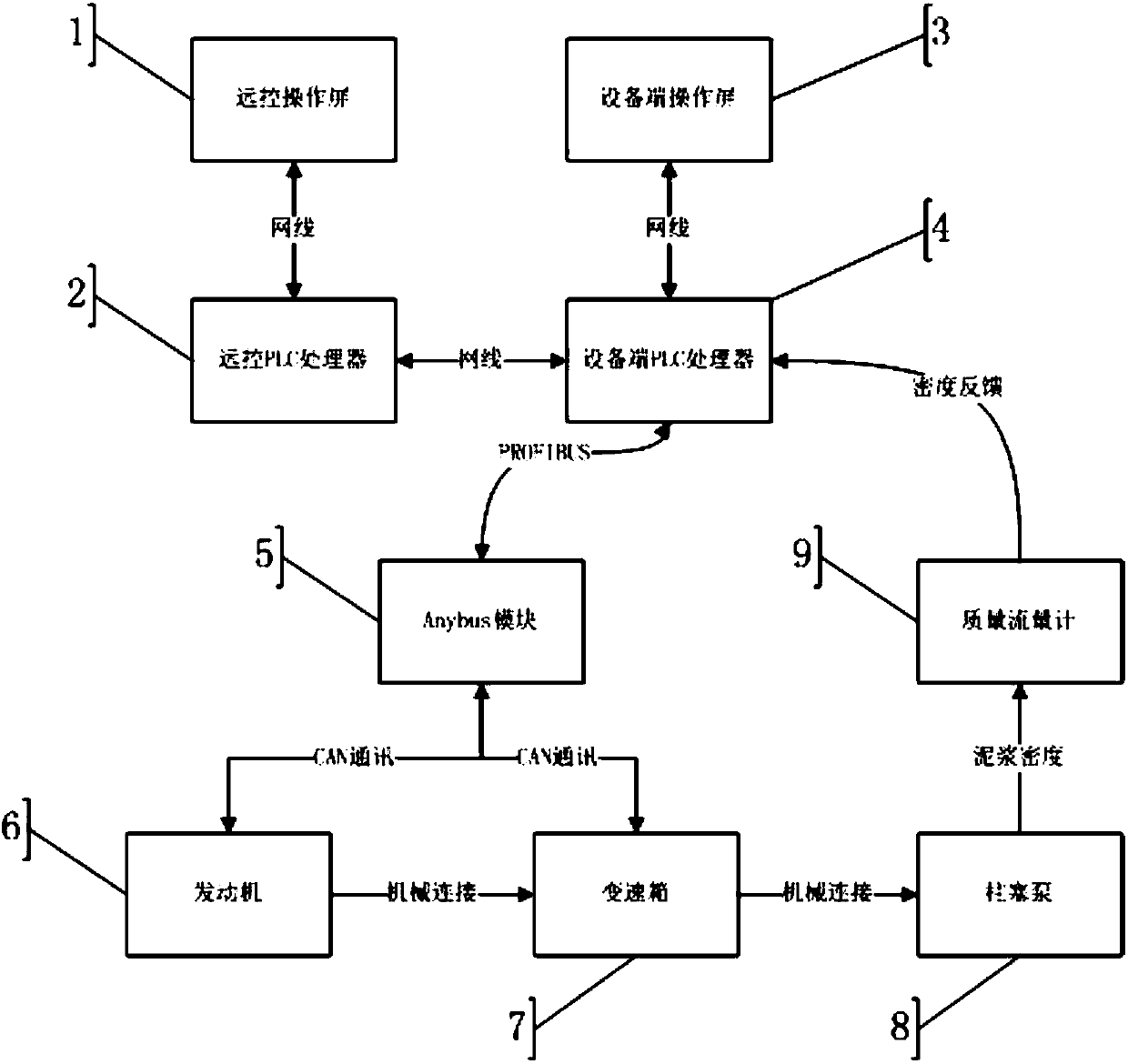

[0014] Combine below figure 1 Explain in detail the remote automatic displacement and density automatic control system:

[0015] Such as figure 1 Shown is a schematic diagram of remote automatic displacement and density automatic control. The remote control operation screen 1 and the remote control PLC processor 2 are installed in the remote control box, and the two are connected through a network cable. The remote control PLC processor 2 in the remote control box is connected to the device-side PLC processor 4 through a network cable, so that the remote control box can operate and control the device-side PLC processor 4 through the remote control operation screen 1 . The device-side PLC processor 4 is connected to the device-side operation screen 3 through a network cable for data display and device operation. The PLC processor 4 of the equipment side, the ECU of the engine 6, and the TCM of the gearbox 7 carry out protocol conversion between PROFIBUS and CAN communication...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com