Remote ultra-low-density automatic control system

An automatic control system and ultra-low density technology, applied in the field of petroleum equipment, can solve the problems such as the inability of the density meter to detect the amount of ash and the inability to use low-density cementing operations, and achieve the effect of improving the level of process automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

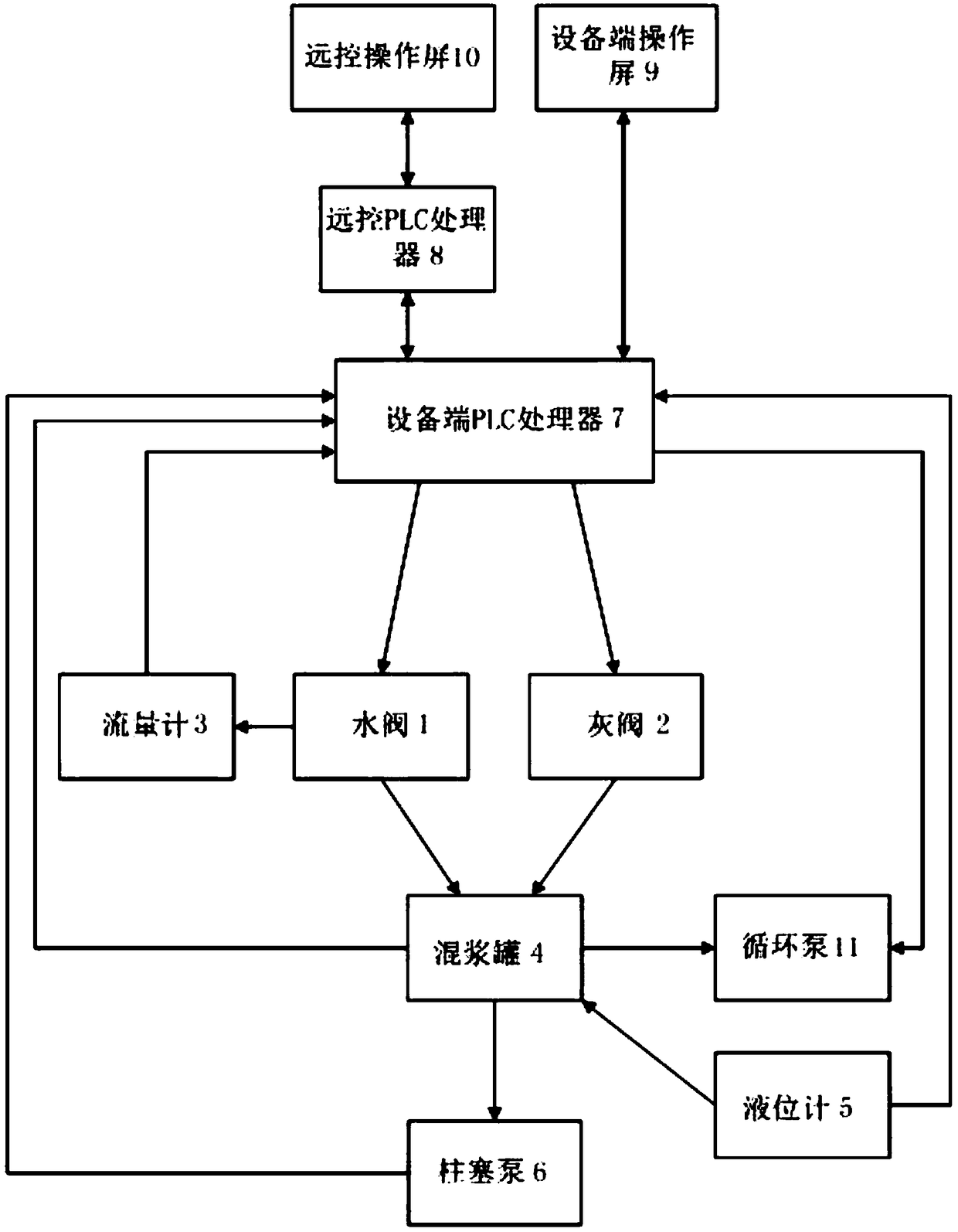

[0011] Such as figure 1 As shown, a remote ultra-low density automatic control system includes a control unit, a water valve 1, an ash valve 2, a flow meter 3, a mixing tank 4, a liquid level gauge 5, a circulation pump 11 and a plunger pump 6, and the water supply is sequentially Enter the mixing tank 4 through the flow meter 3 and the water valve 1, the flow meter 3 will feed back the real-time monitored water supply to the control unit, and the ash will enter the mixing tank 4 through the ash valve 2 for metering the mixing tank 4 The liquid level gauge 5 of the liquid level value is set in the mixing tank 4, and the circulation pump 11 is used for mixing the slurry in the mixing tank 4. The control unit realizes automatic on-demand by controlling the number of revolutions and preset displacement of the plunger pump 6. Displacement, the water-cement ratio and liquid level value are preset in the control unit, and the water demand and ash demand are calculated to control the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com