Silicon substrate micro-channel heat exchanger with electric fluid power micro-pump and manufacturing method thereof

A micro-channel heat exchanger and electro-fluid technology, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of incompatibility in the field of microelectronics heat dissipation, poor flow control accuracy, and large volume. To achieve the effect of stable flow, reliable operation and accurate flow control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

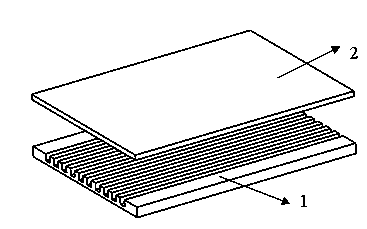

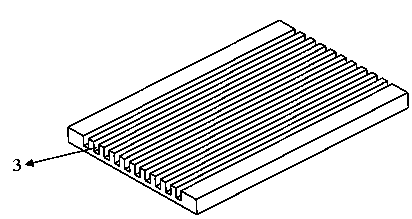

[0035] Such as Figure 1-3 As shown, a silicon-based microchannel heat exchanger with an electrohydrodynamic micropump includes a top plate 2 and a silicon substrate 1 that are closely fitted up and down. The bottom surface of the top plate 2 has the same shape and size as that of the silicon substrate 1. The silicon substrate 1 The upper surface is etched along the length direction with micro-grooves 3 through the reactive ion etching method, and the hydraulic diameter of the micro-grooves 3 is 10um~3mm;

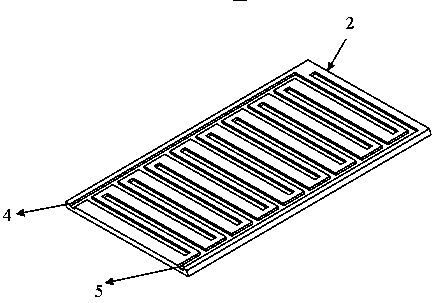

[0036] The top plate 2 is made of aluminum nitride, and the side of the top plate 2 facing the silicon substrate 1 is processed with an electrofluidic power micropump. The electrofluidic power micropump includes an emitter groove 4 and a collector groove processed with a comb-shaped structure. Groove 5, the depth of the emitter groove 4 and the collector groove 5 is 20-40μm, the emitter groove 4 and the collector groove 5 are arranged in parallel and staggered, and the grooves...

Embodiment 2

[0040] The manufacturing method of silicon-based microchannel heat exchanger with electrohydrodynamic micropump includes the steps:

[0041] (1) The emitter trench 4 and the collector trench 5 are processed on the top plate 2 respectively, and the through micro trench 3 is etched along the length direction by the reactive ion etching method on the silicon substrate 1. The top plate 2 uses laser Engraving technology, engraving the comb-tooth-shaped emitter groove 4 and collector groove 5 on the aluminum nitride top plate 2 and removing the burrs and corners on the edge of the groove;

[0042] (2) Using gold immersion treatment or ion sputtering process, the emitter trench 4 and the collector trench 5 in step 1 are plated with gold to prepare the emitter and collector;

[0043] (3) Using an evaporation process, the surface of the top plate after the step (2) is coated with a layer of aluminum nitride film with a thickness of 0.5um~2um;

[0044] (4) The processed top plate 2 and the sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com