Vane type throttle valve

A throttle valve and vane-type technology, which is applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of difficulty in controlling the vacuum degree of equipment, inability to accurately control fluid flow, gas waste, etc., and achieve the effect of saving fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

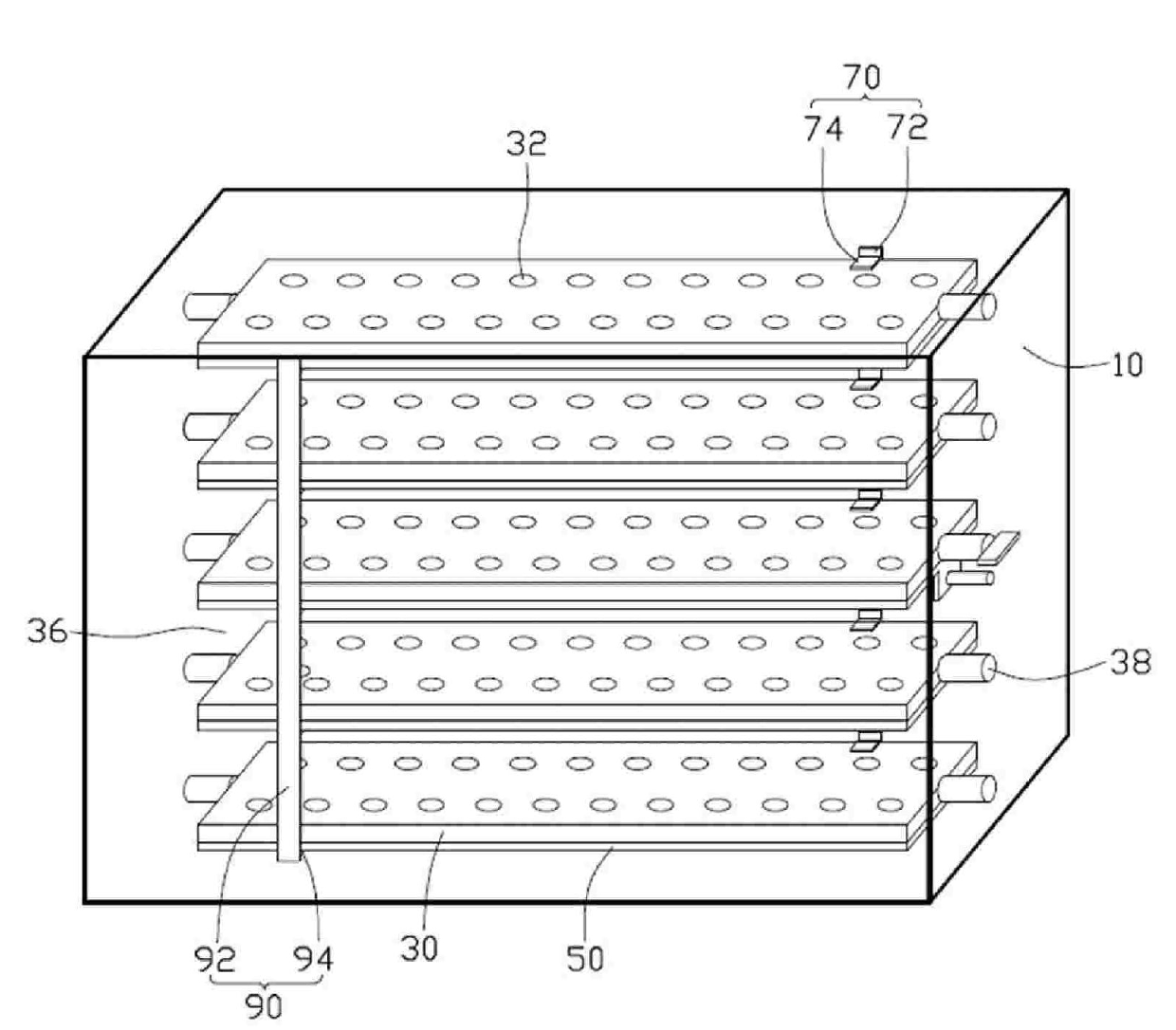

[0014] Such as figure 1 As shown, a vane throttle valve according to a preferred embodiment of the present invention includes a casing 10 , a plurality of vanes 30 and a plurality of baffles 50 disposed in the casing 10 .

[0015] The number of blades 30 can be changed according to needs. In this embodiment, only five blades 30 are shown for simplicity of illustration. The blades 30 are evenly spaced and connected as a whole by a connecting piece 70. The connecting piece 70 includes a lengthwise connecting rod 72 and several connecting pieces 74 rotatably connected to the connecting rod 72. The connecting pieces 74 The quantity is set according to the number of blades 30 , and each connecting piece 74 is connected to the upper surface of a blade 30 , and the way of connecting the connecting piece 74 and the blade 30 can be sticking, welding and the like.

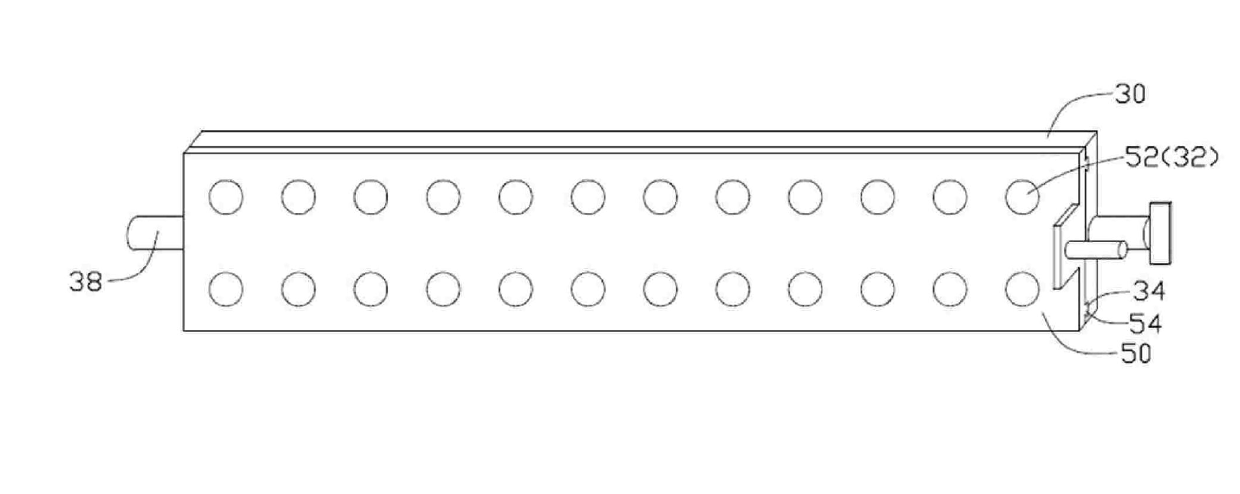

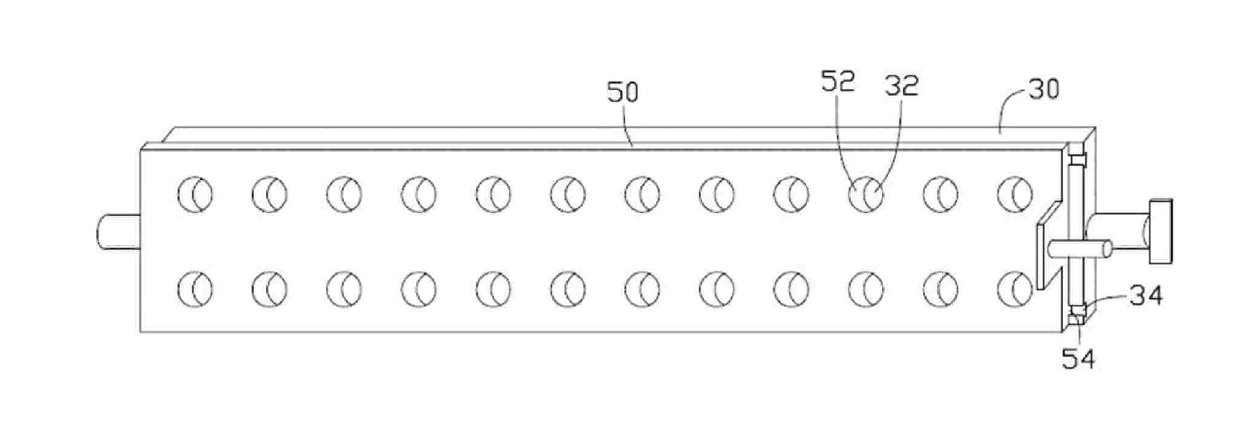

[0016] Each blade 30 is in the shape of a thin plate, and the blade 30 is provided with a plurality of through holes 32 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com