Active control type electrolysing solution flowing method in blade process and electrolysing solution circulating system

An electrolyte and control technology, which is applied in the direction of processing working medium supply, etc., can solve problems such as blank vibration, uneven electrolyte flow, and flow direction cannot be changed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

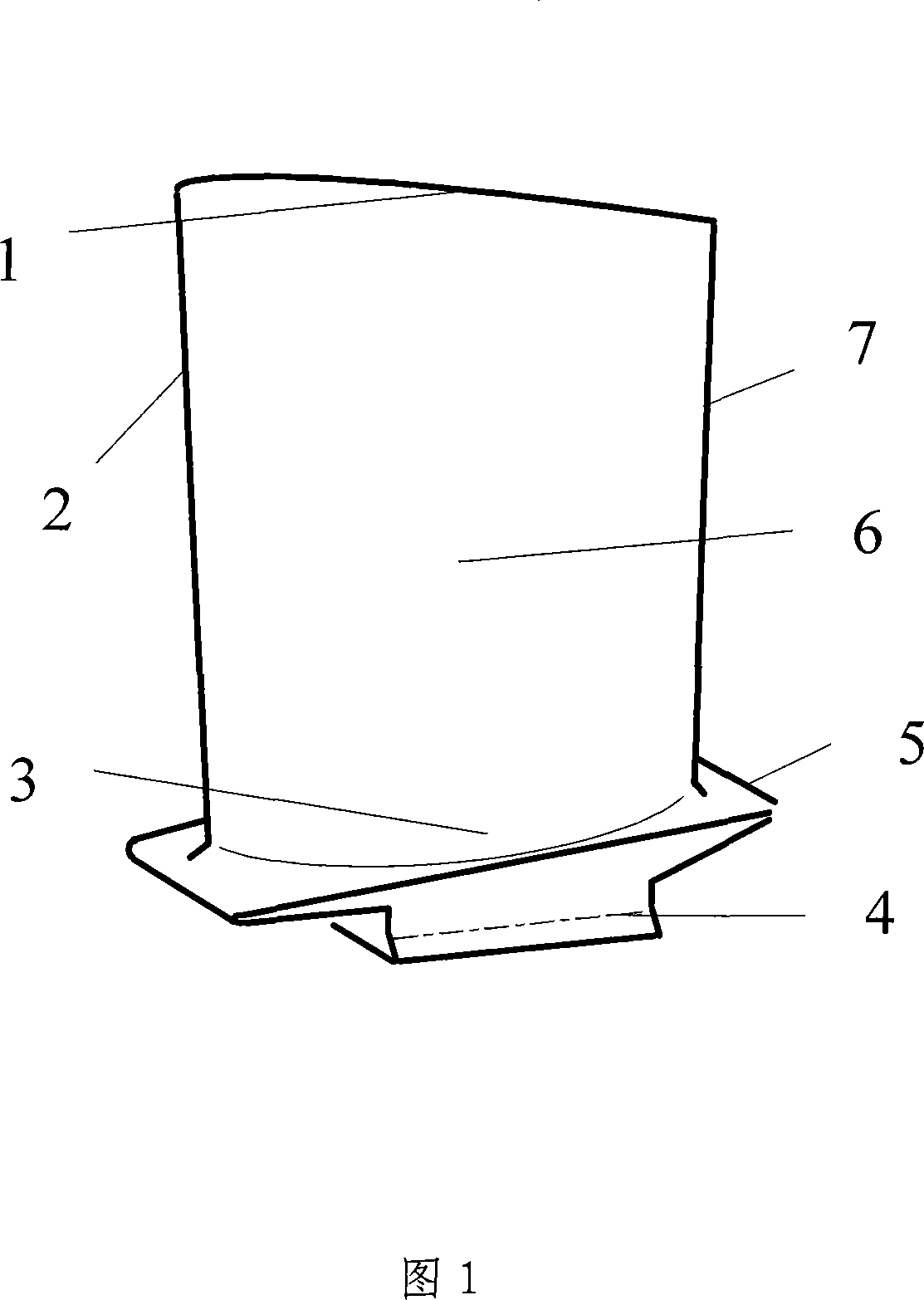

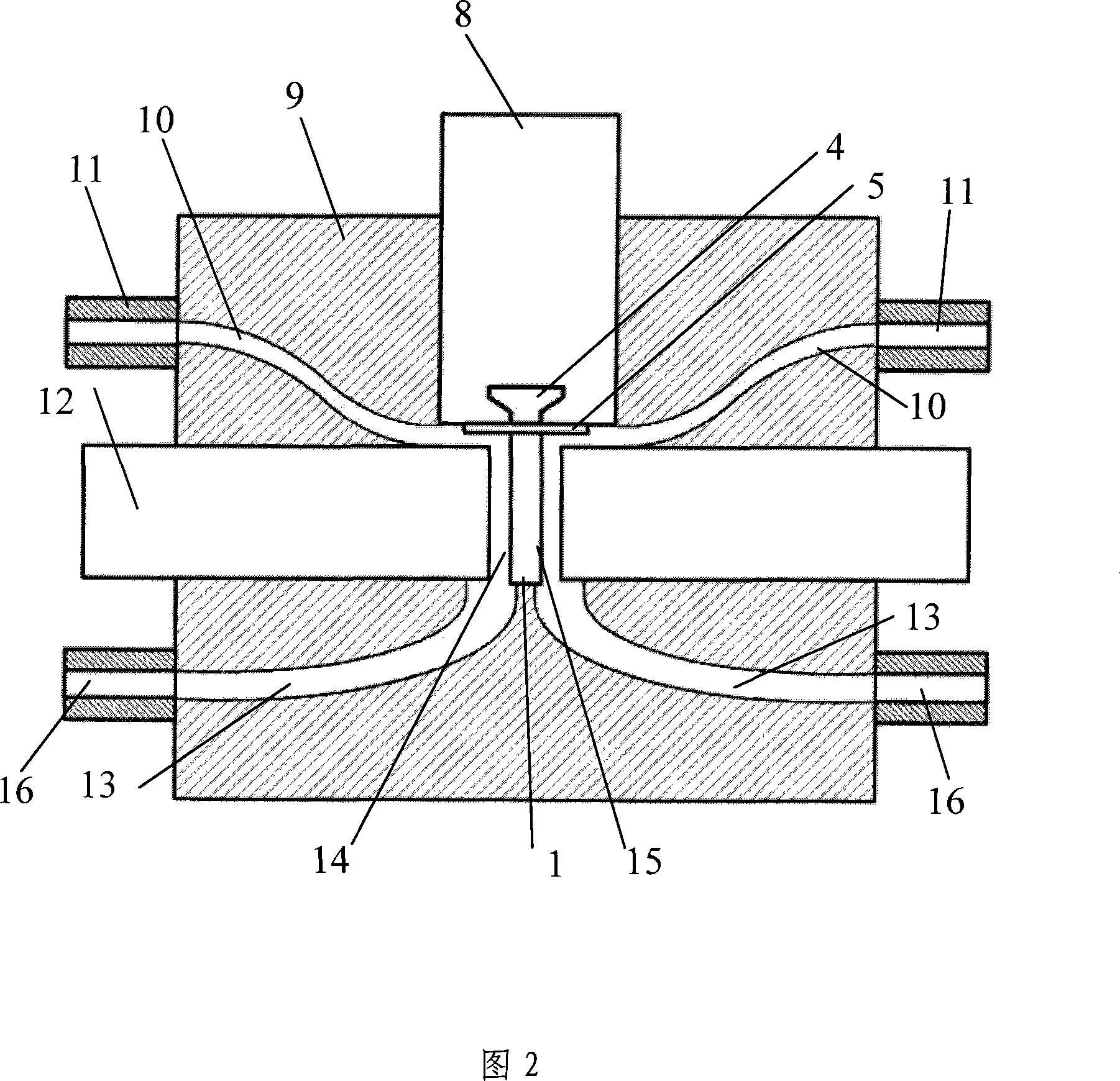

[0033] As shown in Figures 1 and 2, the electrolyte splitting device is included in the fixture 9, and the main part of the fixture 9 is made of insulating materials such as epoxy resin. There are four flow channels extending from the edge to the processing area around the inside of the fixture 9, which correspond to each other, respectively, the electrolyte inflow (outflow) channel 10 and the electrolyte outflow (inflow) channel 13, and the electrolyte inflow (outflow) The ends of the channel 10 and the electrolyte outflow (inflow) channel 13 are connected with four inlet or outlet ports of the electrolyte, and the electrolyte is introduced into the electrolyte inflow (outflow) channel 10 through the inlet or outlet ports of the electrolyte And the electrolyte solution flows out (flows) into the channel 13 .

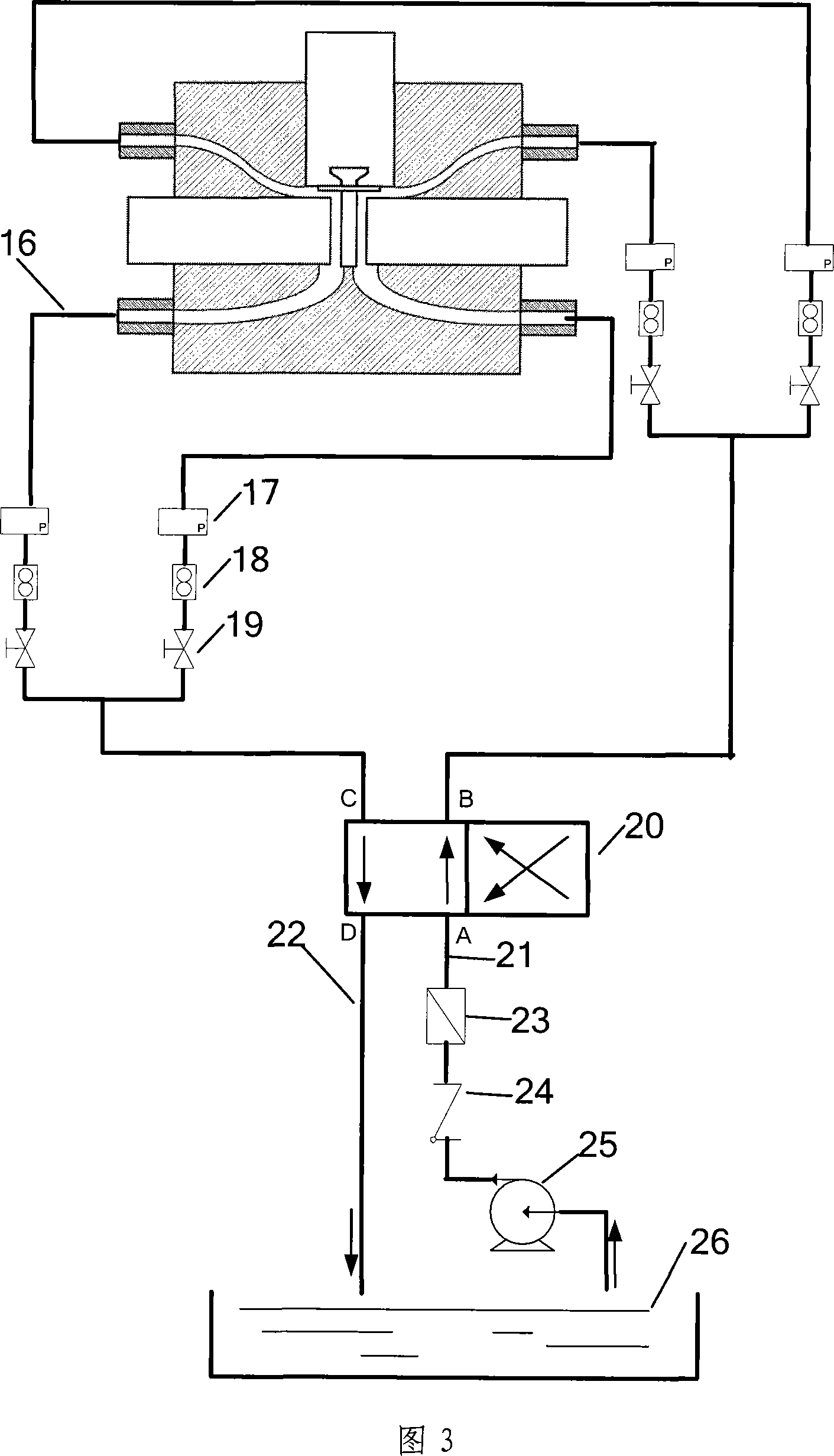

[0034] As shown in Figure 3, it is a schematic diagram of the electrolyte flow equalization and reversing device. Including 17. Pressure gauge, 18. Flow meter, 19. Reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com