Method for preparing Grignard reagent

A Grignard reagent and Grignard reaction technology, which is applied in the field of Grignard reagent preparation, can solve the problems of deterioration, Grignard reagent contact with air, etc., and achieve the effects of improving utilization rate, facilitating recycling, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

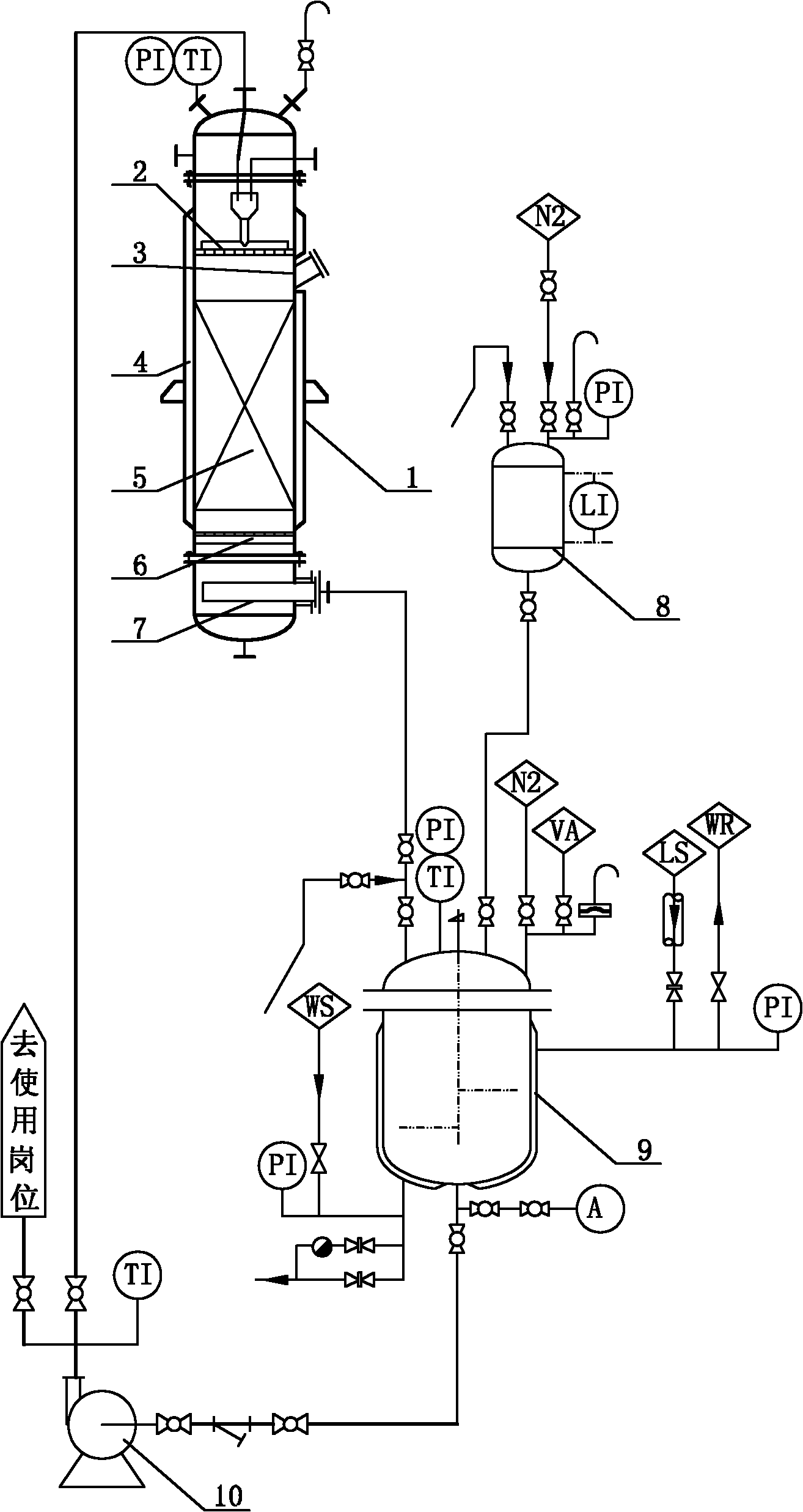

[0020] exist figure 1 In the external circulation Grignard reagent preparation device, the reaction equipment is a reaction kettle 9 and a magnesium ingot tower 1 connected in series with it, and large-grained magnesium or magnesium ingots 5 are placed in the magnesium ingot tower 1, and the magnesium ingot tower 1 is provided with for supporting large The support plate 6 of granular magnesium or magnesium ingot and the filter element 7 located under the support plate, the magnesium ingot tower has a jacket 4 outside, add solvent and initiator to the reaction kettle for Grignard reaction, and the liquid filtered by the filter element flows into the reaction kettle 9, the liquid coming out of the bottom of the reaction kettle is pumped back into the magnesium ingot tower with a circulation pump 10, and the liquid is sprayed to large-grained magnesium or magnesium ingots through the distributor 2 located at the upper part of the magnesium ingot tower. Feeding port 3 below the di...

Embodiment 2

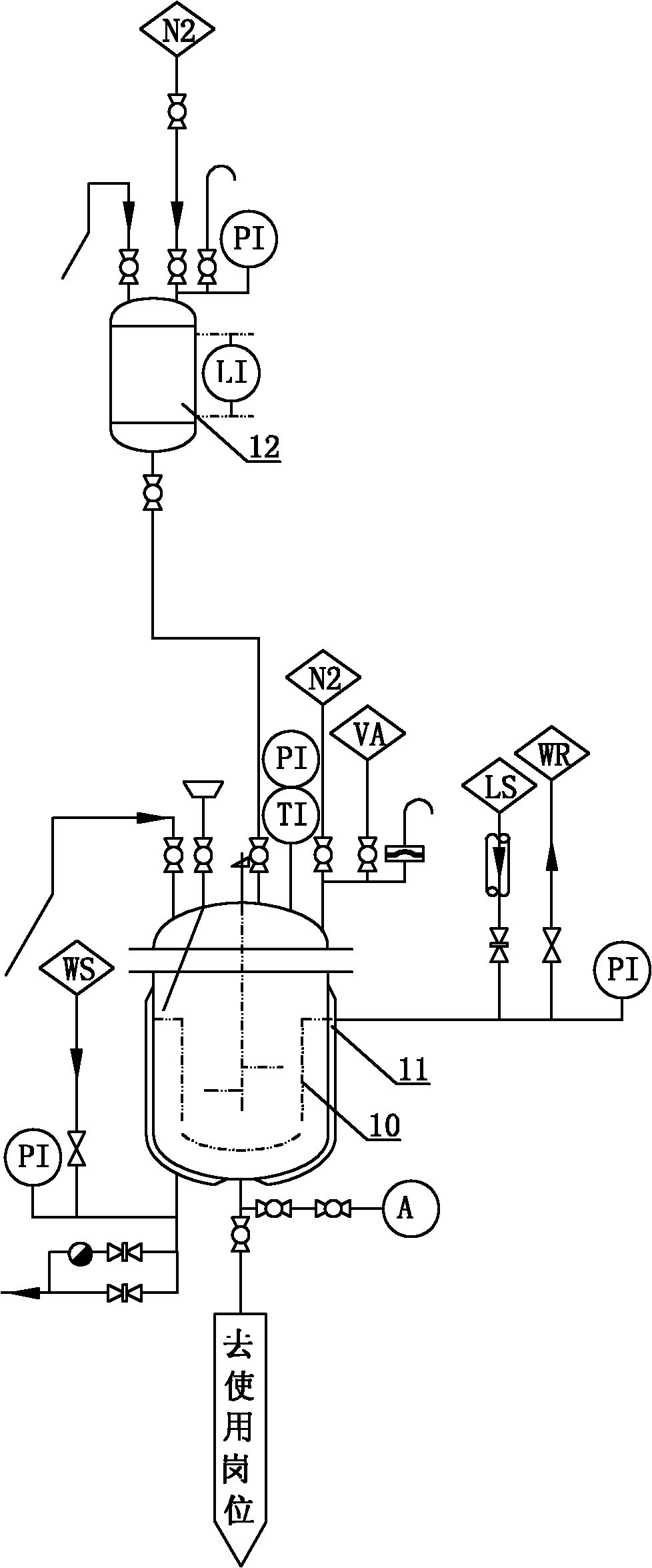

[0027] exist figure 2 In the kettle reaction Grignard reagent preparation device (the reaction kettle volume is 500L). Magnesium is in a static state, and stainless steel wire mesh is used to make a net bag 11 and fixed on the wall of the reaction kettle 12. The magnesium is placed in the net bag, and the mesh hole diameter of the net bag is ≤5mm.

[0028] The specific preparation method is as follows: put 200Kg (10*10*20) of metal magnesium particles into the magnesium fixed net bag around the reaction kettle by using the feeding pipe in advance, put 95L of tetrahydrofuran into the reaction kettle by using vacuum, and add 0.12Kg of iodine as an initiator. Nitrogen replacement was carried out in the reactor. After replacement, close the drain port. Open the jacket of the reaction kettle to heat the steam, adjust the steam pressure to 0.05MPa, perform slow heating, adjust the steam pressure, and control the temperature inside the kettle at 80-90°C. The mixed liquid of 40Kg ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com