Plastic electric-spraying throttle valve body assembly

A technology of electric fuel injection throttle and throttle, which is applied in the direction of mechanical equipment, engine control, machine/engine, etc., can solve the problems of different thermal expansion coefficients of metal and plastic, leakage of bypass channels, etc., to achieve rapid exchange, avoid leakage, avoid The effect of large size changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

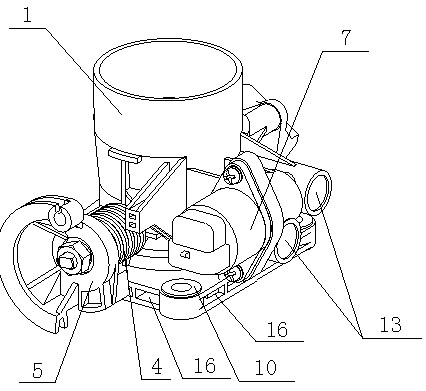

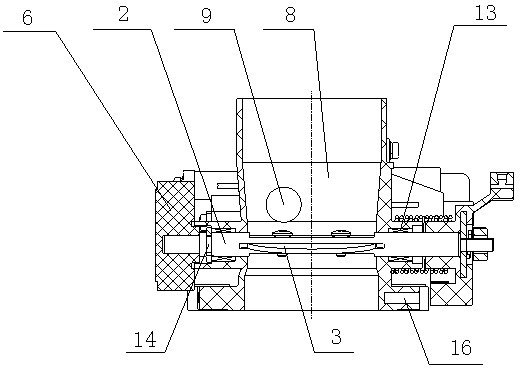

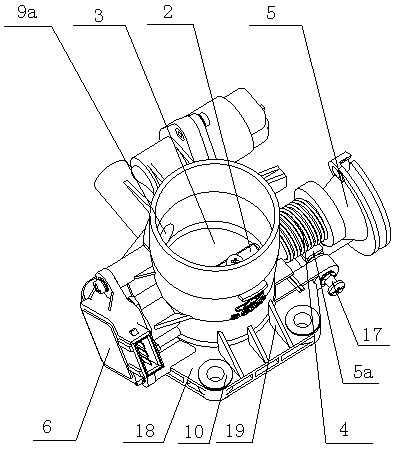

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a plastic EFI throttle body assembly includes a throttle body 1, a throttle shaft 2, a throttle plate 3, a torsion spring 4, a swivel frame 5, a position sensor 6, a stepping motor 7, and a card 14 , Idle adjustment screw 17 and flange 18.

[0028] Throttle valve body 1 is a uniform thin-walled structure, using PPS plastic plus glass fiber as the base material for one-time injection molding, including the intake main channel 8 and idle speed bypass channel 9, the metal insert 10 is fixed on the flange 18, and the intake air A number of reinforcing ribs 19 are provided at the connection between the main channel and the flange 18 .

[0029] The throttle body 1 includes an idle screw mounting insert 11, a stepping motor and position sensor mounting insert 12 and a flange mounting insert 10, and the stepp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com