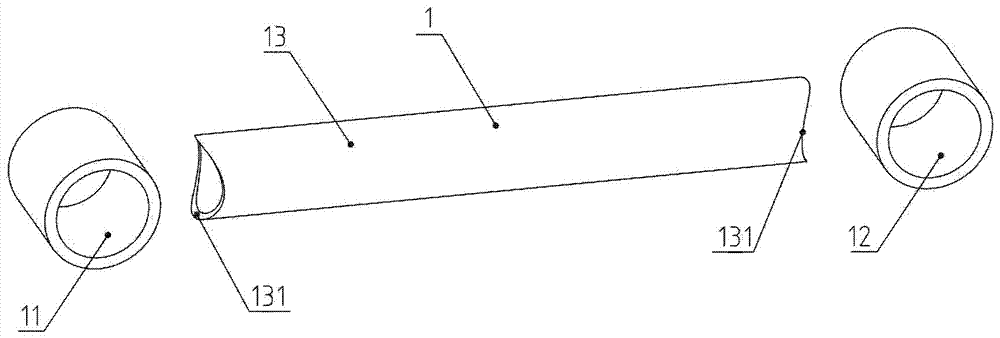

Semi-automatic welding positioner of double-lug-ring connecting rod

A semi-automatic welding and positioner technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low efficiency, multiple chips, and difficulty in recruiting workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

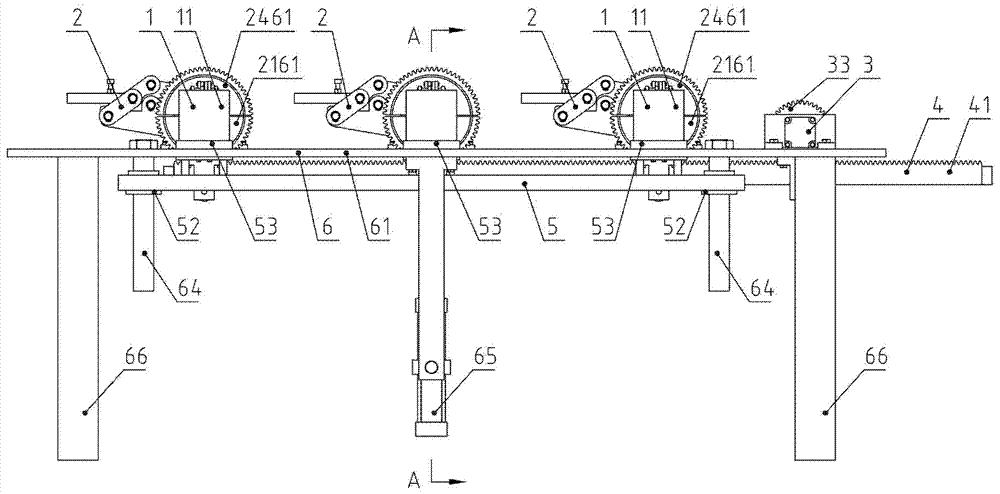

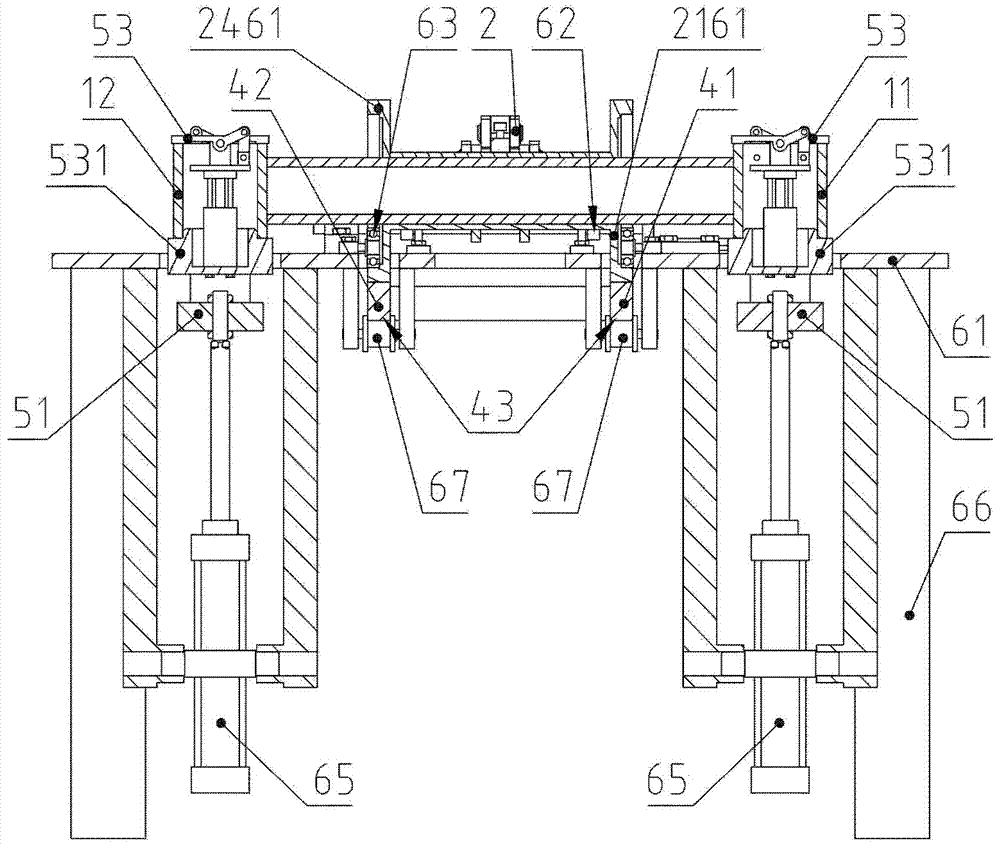

[0059] Example: see Figure 1 to Figure 23 .

[0060] A semi-automatic welding positioner for clevis connecting rods, including three gear assemblies 2, a servo motor assembly 3, a rack frame 4, two lifting assemblies 5 and a platform assembly 6;

[0061] The platform assembly 6 includes a platform surface 61, an outer ring bearing 62, an inner ring bearing 63, a guide rod 64, two lifting cylinders 65, supporting legs 66 and a rack back sheave 67; the platform surface 61 is set horizontally, and the supporting legs 66 are fixed Connected to the bottom of the platform surface 61; the platform surface 61 is provided with a transparent earring positioning through hole 611, a gear assembly avoidance hole 612, a driven gear avoidance hole 613 and a driving gear avoidance hole 614, and the gear assembly avoidance hole 612 is a rectangle. Located in the middle of the platform surface 61, driven gear avoidance holes 613 are symmetrically distributed on both sides of the gear assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com