Method for preparing silicon-aluminum alloy electronic packaging material by virtue of rapid injection molding

An electronic packaging material and a silicon-aluminum alloy technology are applied in the field of rapid injection molding to prepare silicon-aluminum alloy electronic packaging materials, which can solve the problems of difficult composition control, difficult forming, and high equipment requirements, and achieve process controllability and repeatability. Avoid machining processes, the effect of low specific gravity of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

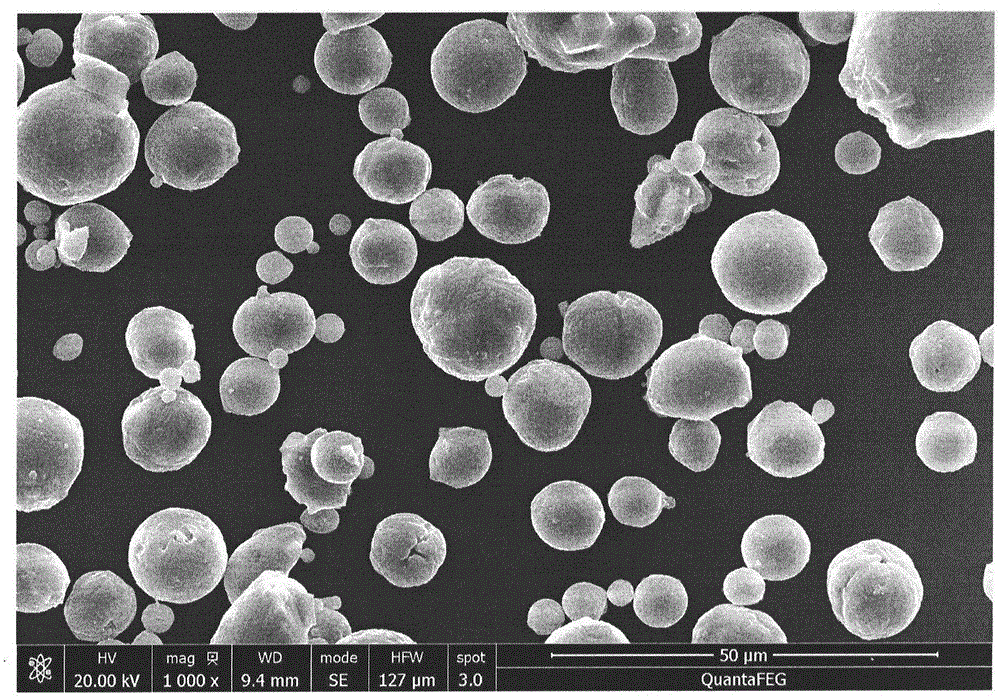

[0022] A method for preparing silicon-aluminum alloy electronic packaging materials by rapid injection molding, the steps are as follows: uniformly mix silicon powder with a weight ratio of 60% and aluminum powder with a weight ratio of 40% to prepare silicon-aluminum alloy powder with a particle size of 50 μm, such as figure 1 ; Mix the silicon-aluminum alloy powder and a certain amount of binder on an internal mixer at 190°C for 2 hours to obtain a uniformly mixed feed; after the feed is crushed, it is injected into the injection machine at a temperature of 180°C and a pressure of 110MPa for 25s Time rapid injection molding to obtain green bodies with corresponding structures; after thermally removing the binder, the green bodies were sintered at 650 °C with a heating rate of 300 °C / h under vacuum conditions, and the holding time was 5 h to obtain relative A silicon-aluminum alloy electronic packaging composite material with a density of 97%.

Embodiment 2

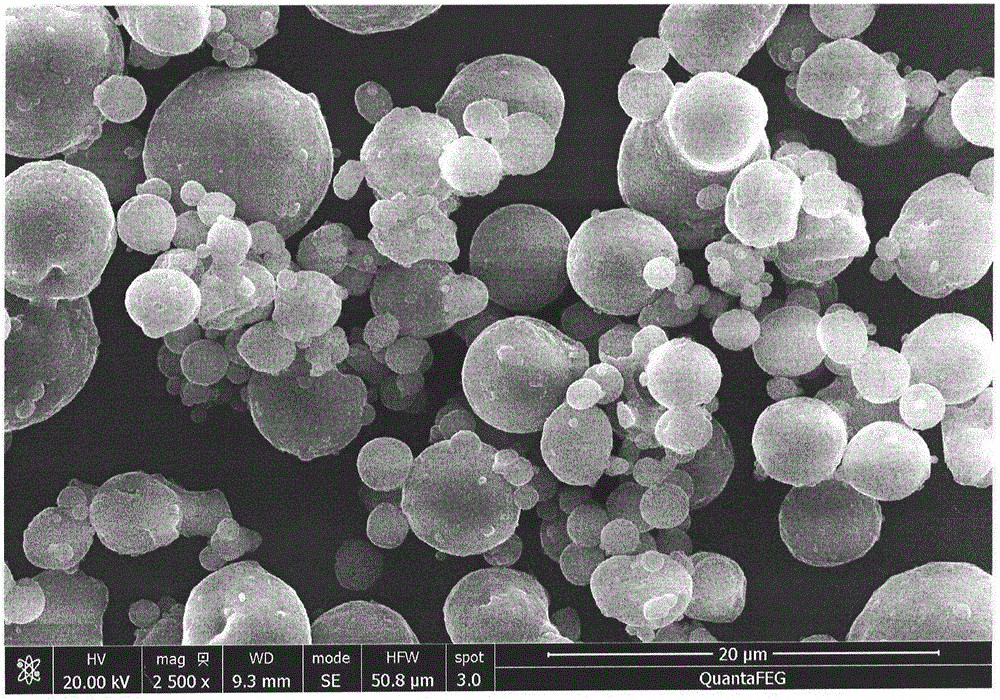

[0024] A method for preparing silicon-aluminum alloy electronic packaging materials by rapid injection molding, the steps are as follows: uniformly mix 10% silicon powder and 90% aluminum powder by weight to make silicon-aluminum alloy powder with a particle size of 5 μm, such as figure 2 ; Mix the silicon-aluminum alloy powder and a certain amount of binder on an internal mixer at a temperature of 140°C for 0.5 hours to obtain a uniformly mixed feed; after the feed is crushed, it is injected in the injection machine at a temperature of 155°C and a pressure of 60MPa. Rapid injection molding in 2s to obtain green bodies with corresponding structures; after thermally removing the binder, the green bodies were sintered at 550°C with a heating rate of 120°C / h under vacuum conditions, and the holding time was 1h to obtain A silicon-aluminum alloy electronic packaging composite material with a relative density of 98%.

Embodiment 3

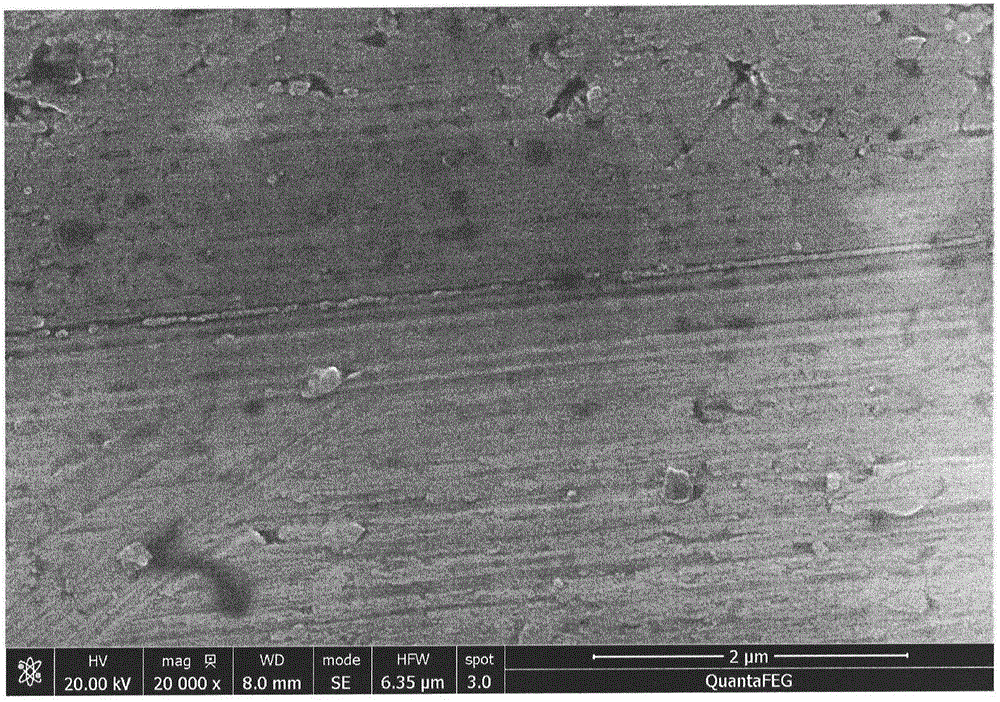

[0026]A method for preparing a silicon-aluminum alloy electronic packaging material by rapid injection molding, the steps are as follows: making a silicon-aluminum alloy powder with a particle size of 25 μm by weight ratio of 40% silicon powder and 60% aluminum powder; mixing the silicon-aluminum alloy powder with a certain A large amount of binder is mixed on the internal mixer at 175°C for 1 hour to obtain a uniformly mixed feed; after the feed is crushed, it is quickly injected into the injection machine at a temperature of 173°C and a pressure of 90 MPa after 5 seconds to obtain the corresponding structure. The green body; after the green body is thermally removed from the binder, it is sintered at a temperature of 580°C, a heating rate of 200°C / h, and a vacuum condition, and the holding time is 3h, to obtain a silicon-aluminum alloy with a relative density of 99%. Electronic packaging composites such as image 3 .

[0027] The structures of the above Examples 1-3 are sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com