Rotating extrusion forming die for cabin workpiece

A technology for extrusion forming and workpieces, which is applied in the field of rotary extrusion forming molds for workpieces in cabins, can solve problems such as waste of materials, and achieve the effects of reducing production costs, reducing post-processing consumption, and avoiding temperature reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

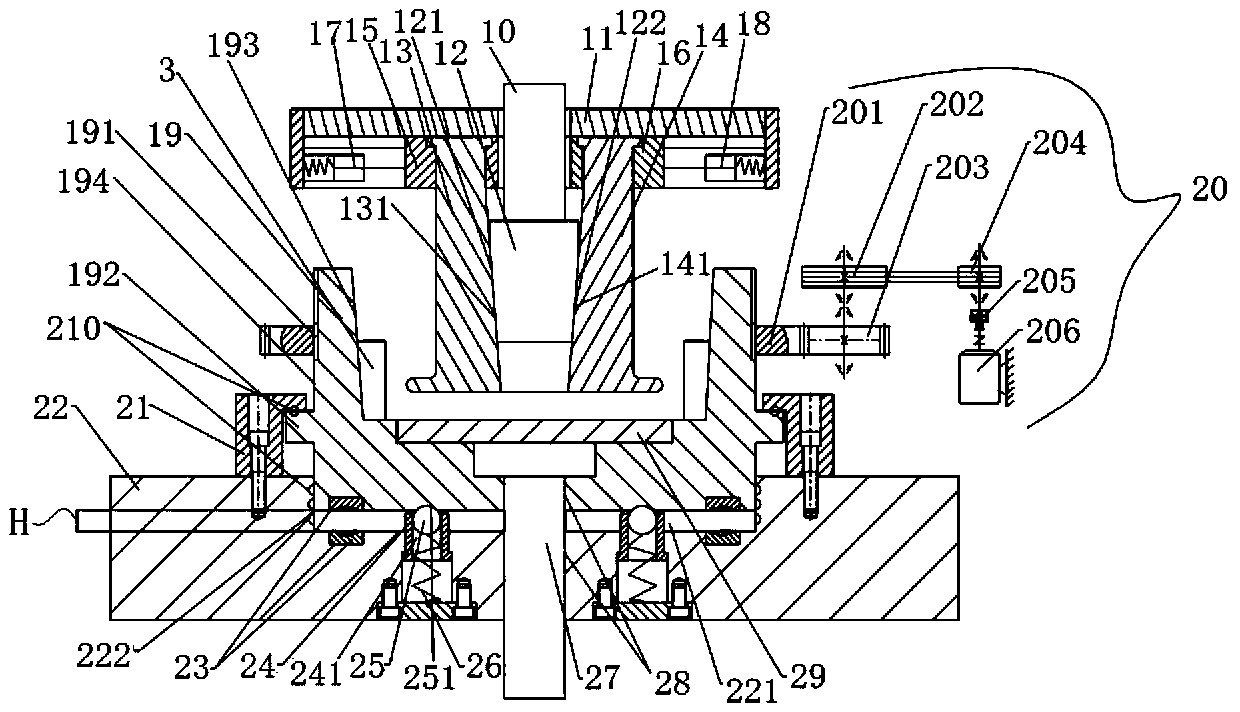

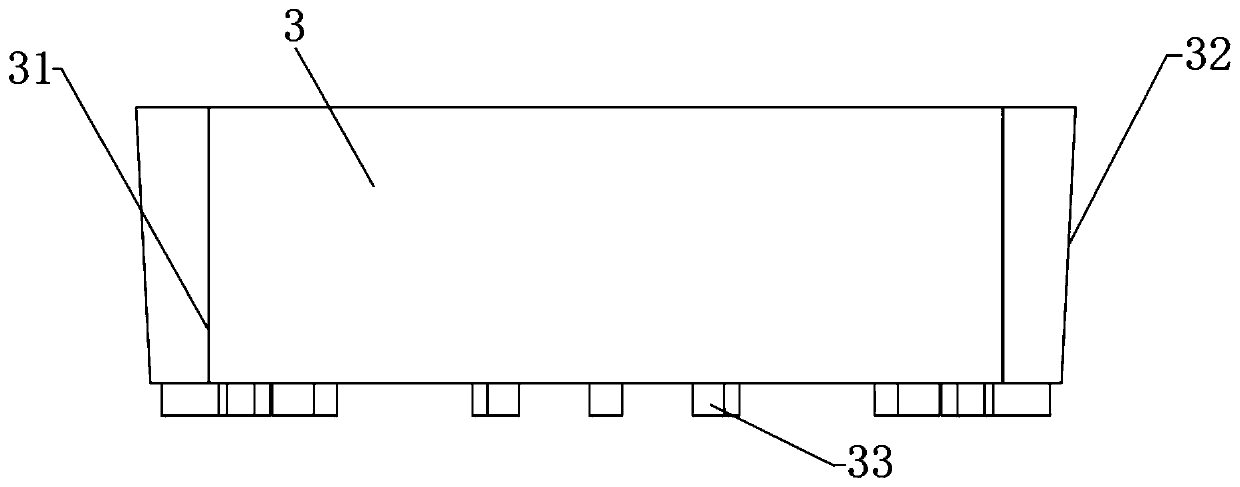

[0042] Such as Figure 1 to Figure 16 As shown, the present invention provides a rotary extrusion molding die for cabin workpieces, which is mainly used for extrusion molding of special-shaped thin-walled cabin workpieces; the forming mold includes a punch, a die 19, an upper mold assembly and a lower mold Base 22; wherein, die 19 is a floating die, which can rotate on lower die base 22 and can float up and down; specifically, die cavity 193 is provided in die 19, and die cavity 193 can be used to place and fix blank 3 The die 19 is rotatably arranged on the lower die base 22 around the vertical axis, that is, the groove 19 can rotate horizontally on the upper die base 22; the punch is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com